2.7 Advantages

2.7.1 Why use a Frequency Converter for

Controlling Fans and Pumps?

A frequency converter takes advantage of the fact that

centrifugal fans and pumps follow the laws of propor-

tionality for such fans and pumps. For further information

see the text and figure The Laws of Proportionality.

2.7.2 The Clear Advantage - Energy Savings

The very clear advantage of using a frequency converter

for controlling the speed of fans or pumps lies in the

electricity savings.

When comparing with alternative control systems and

technologies, a frequency converter is the optimum energy

control system for controlling fan and pump systems.

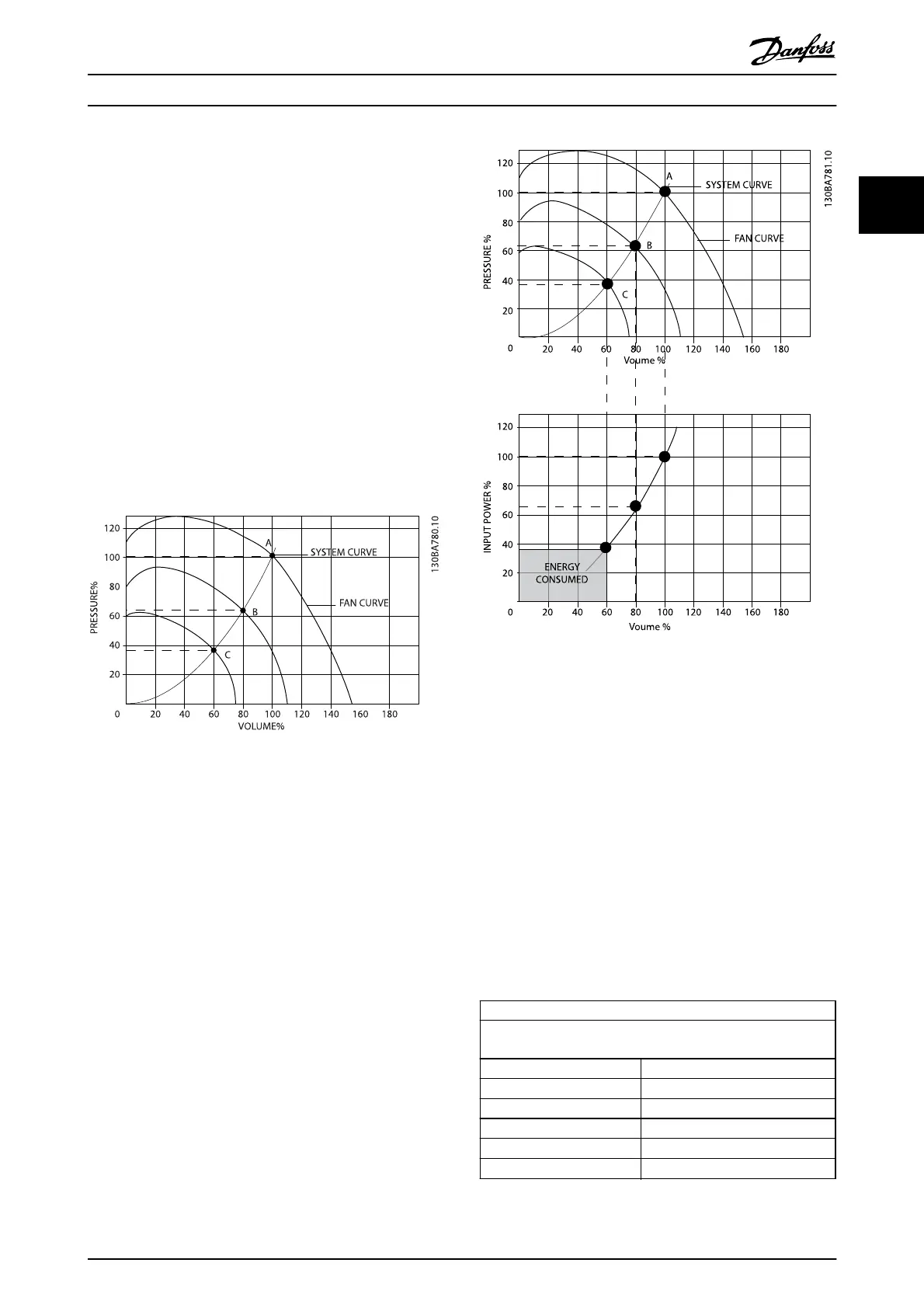

Illustration 2.4 The Graph is Showing Fan Curves (A, B and C) for

Reduced Fan Volumes.

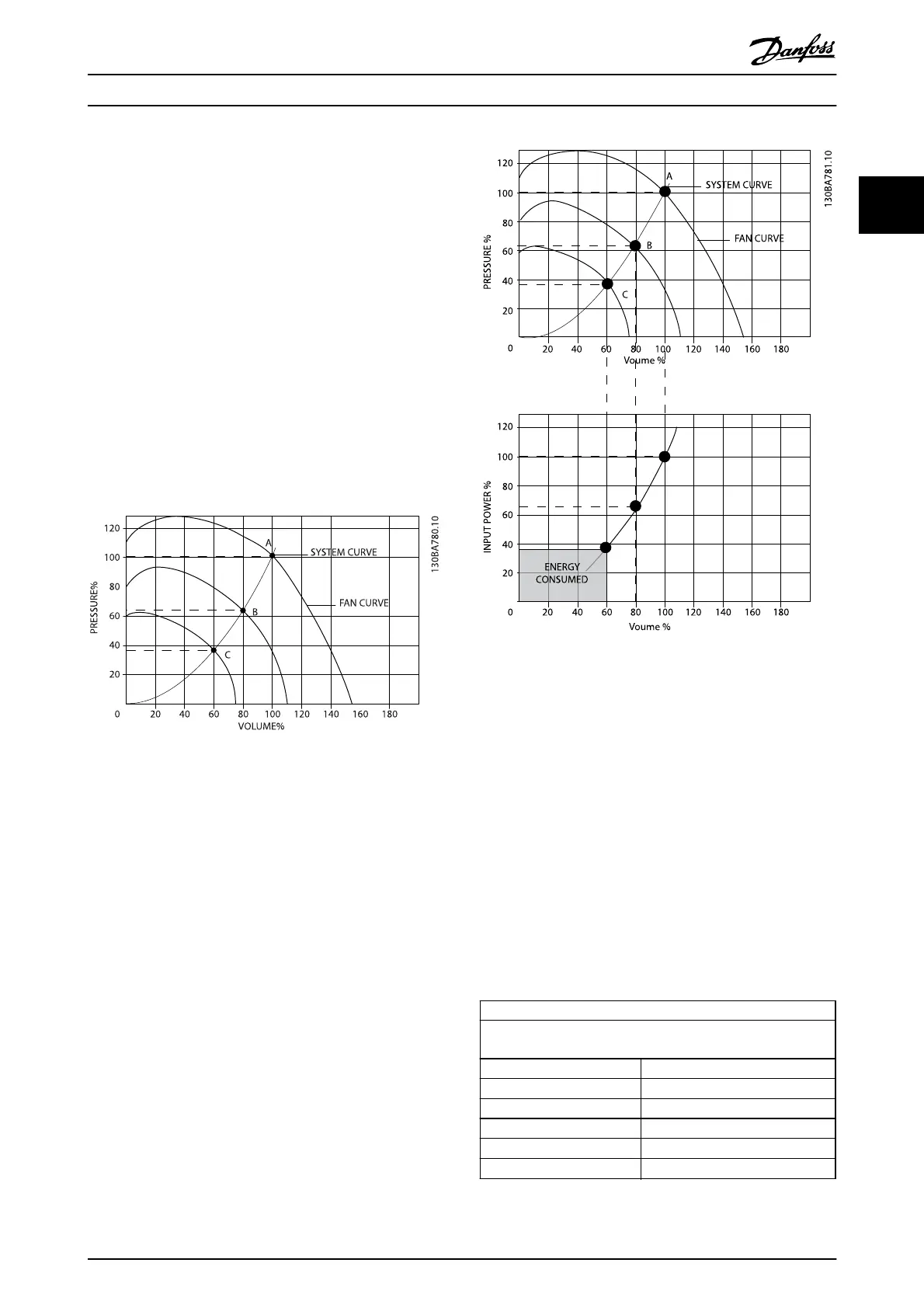

Illustration 2.5 When Using a Frequency Converter to Reduce

Fan Capacity to 60% - More Than 50% Energy Savings May Be

Obtained in Typical Applications.

2.7.3 Example of Energy Savings

As can be seen from the figure (the laws of propor-

tionality), the flow is controlled by changing the RPM. By

reducing the speed only 20% from the rated speed, the

flow is also reduced by 20%. This is because the flow is

directly proportional to the RPM. The consumption of

electricity, however, is reduced by 50%.

If the system in question only needs to be able to supply a

flow that corresponds to 100% a few days in a year, while

the average is below 80% of the rated flow for the

remainder of the year, the amount of energy saved is even

more than 50%.

The laws of proportionality

Illustration 2.6 describes the dependence of flow, pressure and

power consumption on RPM.

Q = Flow P = Power

Q

1

= Rated flow P

1

= Rated power

Q

2

= Reduced flow P

2

= Reduced power

H = Pressure n = Speed regulation

H

1

= Rated pressure n

1

= Rated speed

H

2

= Reduced pressure n

2

= Reduced speed

Table 2.3

Introduction

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 17

2

Loading...

Loading...