frequency converter. In this example it is less than a year

when compared with valves and constant speed.

Energy savings

P

shaft

=P

shaft output

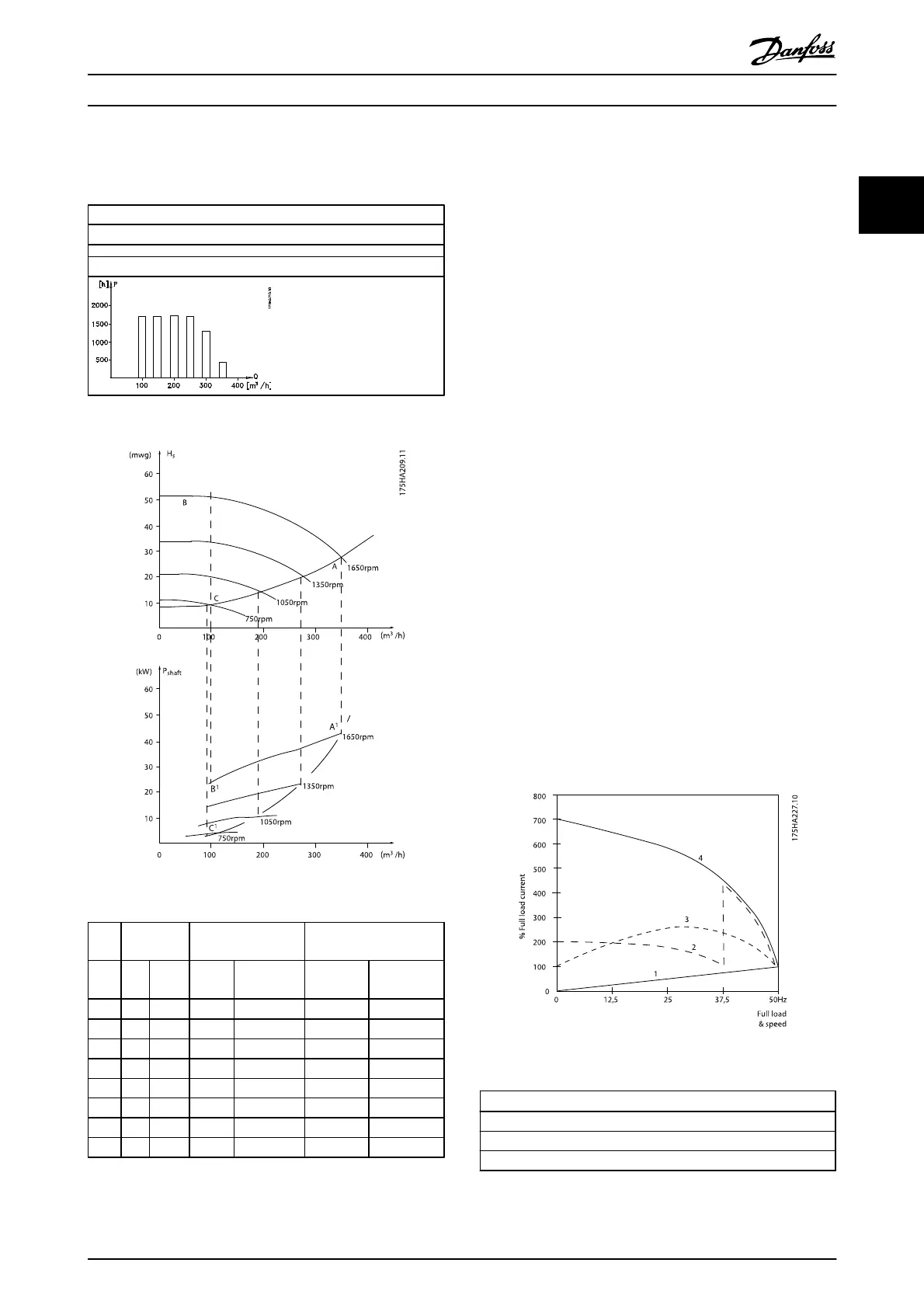

Flow distribution over 1 year

Table 2.4

Illustration 2.9

m

3

/h

Distri-

bution

Valve regulation Frequency converter

control

% Hours Power Consumpti

on

Power Consumptio

n

A

1

- B

1

kWh A

1

- C

1

kWh

350 5 438 42,5 18.615 42,5 18.615

300 15 1314 38,5 50.589 29,0 38.106

250 20 1752 35,0 61.320 18,5 32.412

200 20 1752 31,5 55.188 11,5 20.148

150 20 1752 28,0 49.056 6,5 11.388

100 20 1752 23,0 40.296 3,5 6.132

Σ 100 8760 275.064 26.801

Table 2.5

2.7.6 Better Control

If a frequency converter is used for controlling the flow or

pressure of a system, improved control is obtained.

A frequency converter can vary the speed of the fan or

pump, thereby obtaining variable control of flow and

pressure.

Furthermore, a frequency converter can quickly adapt the

speed of the fan or pump to new flow or pressure

conditions in the system.

Simple control of process (Flow, Level or Pressure) utilizing

the built in PID control.

2.7.7

Cos φ Compensation

Generally speaking, the VLT

®

Refrigeration Drive FCR 103

has a cos φ of 1 and provides power factor correction for

the cos φ of the motor, which means that there is no need

to make allowance for the cos φ of the motor when sizing

the power factor correction unit.

2.7.8 Star/Delta Starter or Soft-starter not

Required

When larger motors are started, it is necessary in many

countries to use equipment that limits the start-up current.

In more traditional systems, a star/delta starter or soft-

starter is widely used. Such motor starters are not required

if a frequency converter is used.

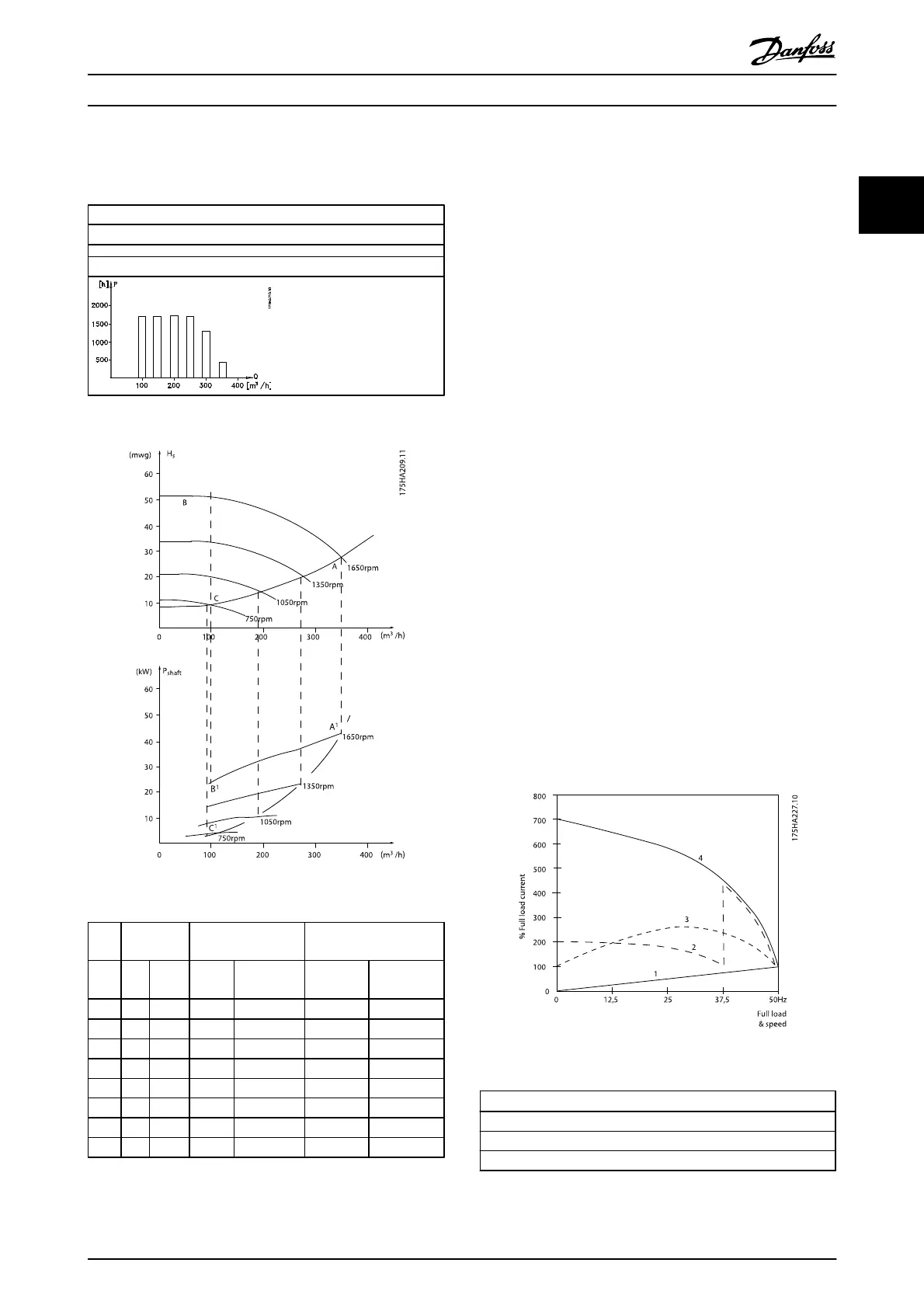

As illustrated in the figure below, a frequency converter

does not consume more than rated current.

Illustration 2.10

1 = VLT

®

Refrigeration Drive FCR 103

2 = Star/delta starter

3 = Soft-starter

4 = Start directly on mains

Table 2.6

Introduction

VLT

®

Refrigeration Drive Design Guide

MG16G102 - VLT

®

is a registered Danfoss trademark 19

2

Loading...

Loading...