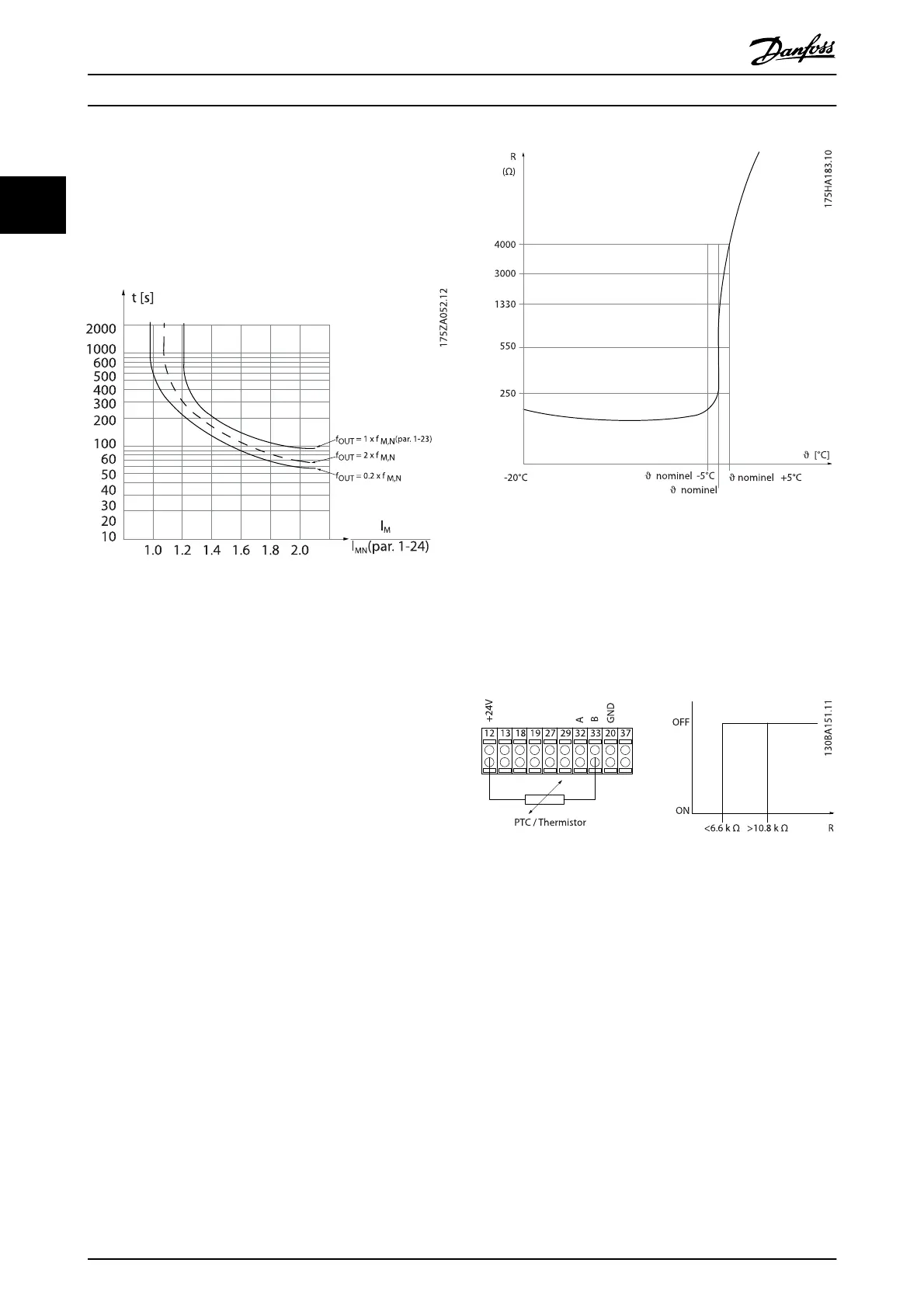

2.12.1 Motor Thermal Protection

This is the way Danfoss is protecting the motor from being

overheated. It is an electronic feature that simulates a

bimetal relay based on internal measurements. The charac-

teristic is shown in Illustration 2.27

Illustration 2.27 The X-axis is showing the ratio between I

motor

and I

motor

nominal. The Y-axis is showing the time in seconds

before the ETR cuts off and trips the frequency converter. The

curves are showing the characteristic nominal speed at twice the

nominal speed and at 0,2x the nominal speed.

It is clear that at lower speed the ETR cuts of at lower heat

due to less cooling of the motor. In that way the motor

are protected from being over heated even at low speed.

The ETR feature is calculating the motor temperature

based on actual current and speed. The calculated

temperature is visible as a read out parameter in

16-18 Motor Thermal in the frequency converter.

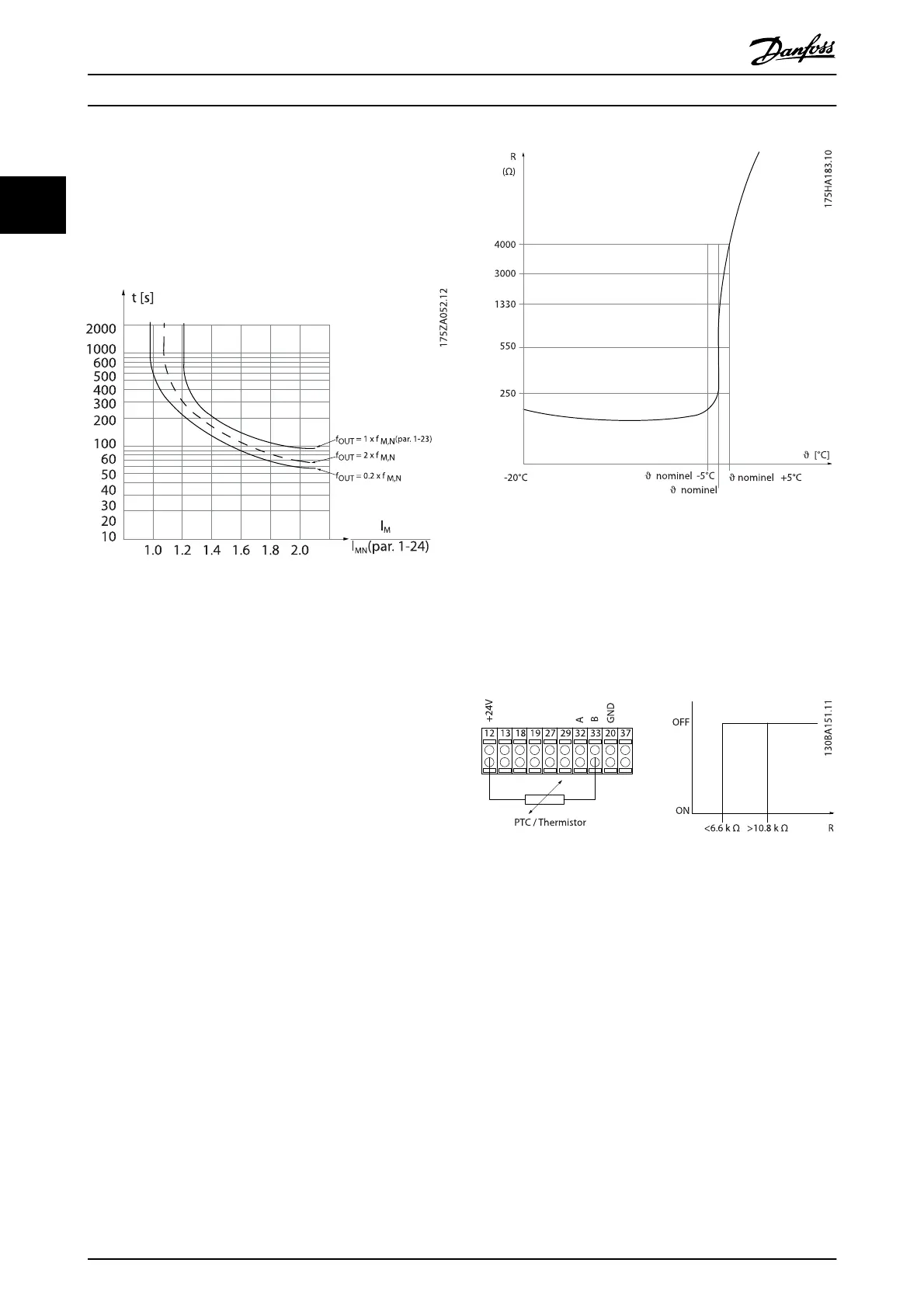

The thermistor cut-out value is > 3 kΩ.

Integrate a thermistor (PTC sensor) in the motor for

winding protection.

Motor protection can be implemented using a range of

techniques: PTC sensor in motor windings; mechanical

thermal switch (Klixon type); or Electronic Thermal Relay

(ETR).

Illustration 2.28

Using a digital input and 24 V as power supply:

Example: The frequency converter trips when the motor

temperature is too high.

Parameter set-up:

Set 1-90 Motor Thermal Protection to [2] Thermistor Trip

Set 1-93 Thermistor Source to [6] Digital Input 33

Illustration 2.29

Using a digital input and 10 V as power supply:

Example: The frequency converter trips when the motor

temperature is too high.

Parameter set-up:

Set 1-90 Motor Thermal Protection to [2] Thermistor Trip

Set 1-93 Thermistor Source to [6] Digital Input 33

Introduction

VLT

®

Refrigeration Drive Design Guide

34 MG16G102 - VLT

®

is a registered Danfoss trademark

2

Loading...

Loading...