Illustration 3.11 Connection to 24 V Backup Supplier (A5-C2).

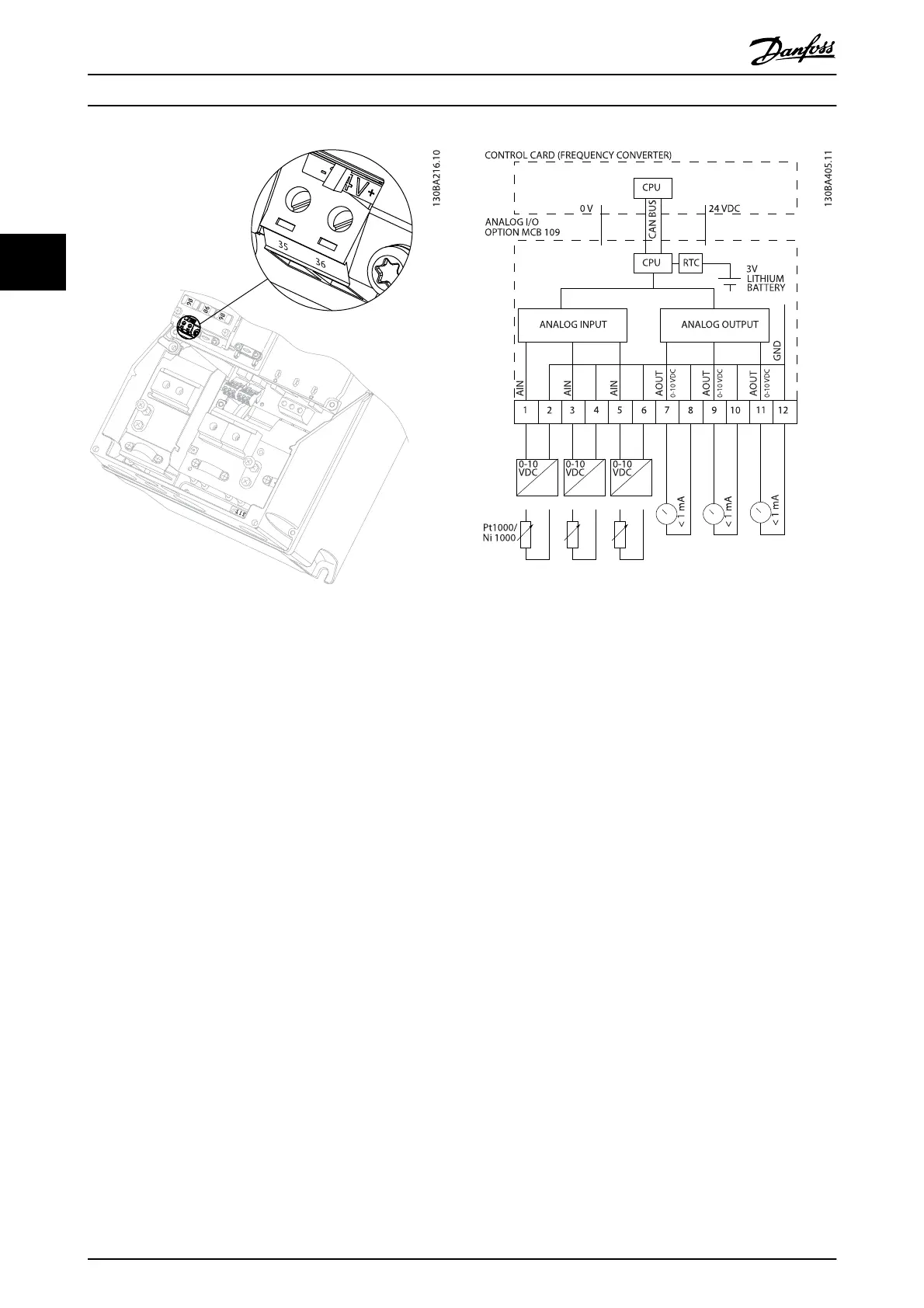

3.1.9 Analog I/O option MCB 109

The Analog I/O card is supposed to be used in e.g. the

following cases:

•

Providing battery back-up of clock function on

control card

•

As general extension of analog I/O selection

available on control card, e.g. for multi-zone

control with three pressure transmitters

•

Turning frequency converter into de-central I/O

block supporting Building Management System

with inputs for sensors and outputs for operating

dampers and valve actuators

•

Support Extended PID controllers with I/Os for set

point inputs, transmitter/sensor inputs and

outputs for actuators.

Illustration 3.12 Principle diagram for Analog I/O mounted in

frequency converter.

Analog I/O configuration

3 x Analog Inputs, capable of handling following:

•

0 - 10 V DC

OR

•

0-20 mA (voltage input 0-10 V) by mounting a

510 Ω resistor across terminals (see NOTE)

•

4-20 mA (voltage input 2-10 V) by mounting a

510 Ω resistor across terminals (see NOTE)

•

Ni1000 temperature sensor of 1000 Ω at 0° C.

Specifications according to DIN43760

•

Pt1000 temperature sensor of 1000 Ω at 0° C.

Specifications according to IEC 60751

3 x Analog Outputs supplying 0-10 V DC.

Drive Selection

VLT

®

Refrigeration Drive Design Guide

42 MG16G102 - VLT

®

is a registered Danfoss trademark

3

Loading...

Loading...