ASDA Series Application Note Introduction of E-Cam Operation

March, 2015

2-43

1. The moving distance of the carrier is 200 mm and the pitch of the ball screw is 10 mm.

It takes 20 rotations for the moving carrier to reach the entire traveling distance.

2. It takes 100000 PUU for the motor to make one rotation. It takes 2000000 PUU in total

for the motor to make 20 rotations.

3. It takes 100000 PUU for the motor to make one rotation and its traveling distance is 10

mm per rotation. It takes 10000 PUU to travel 1 mm.

4. The carrier’s moving distance is 200 mm and the encoder which connects to the master

axis sends 52 pulses every 1 mmWhen the slave axis travels 200 mm, it means the

encoder will send 10,400 (52 x 200) pulses to the slave axis when the slave axis

operates one cycle.

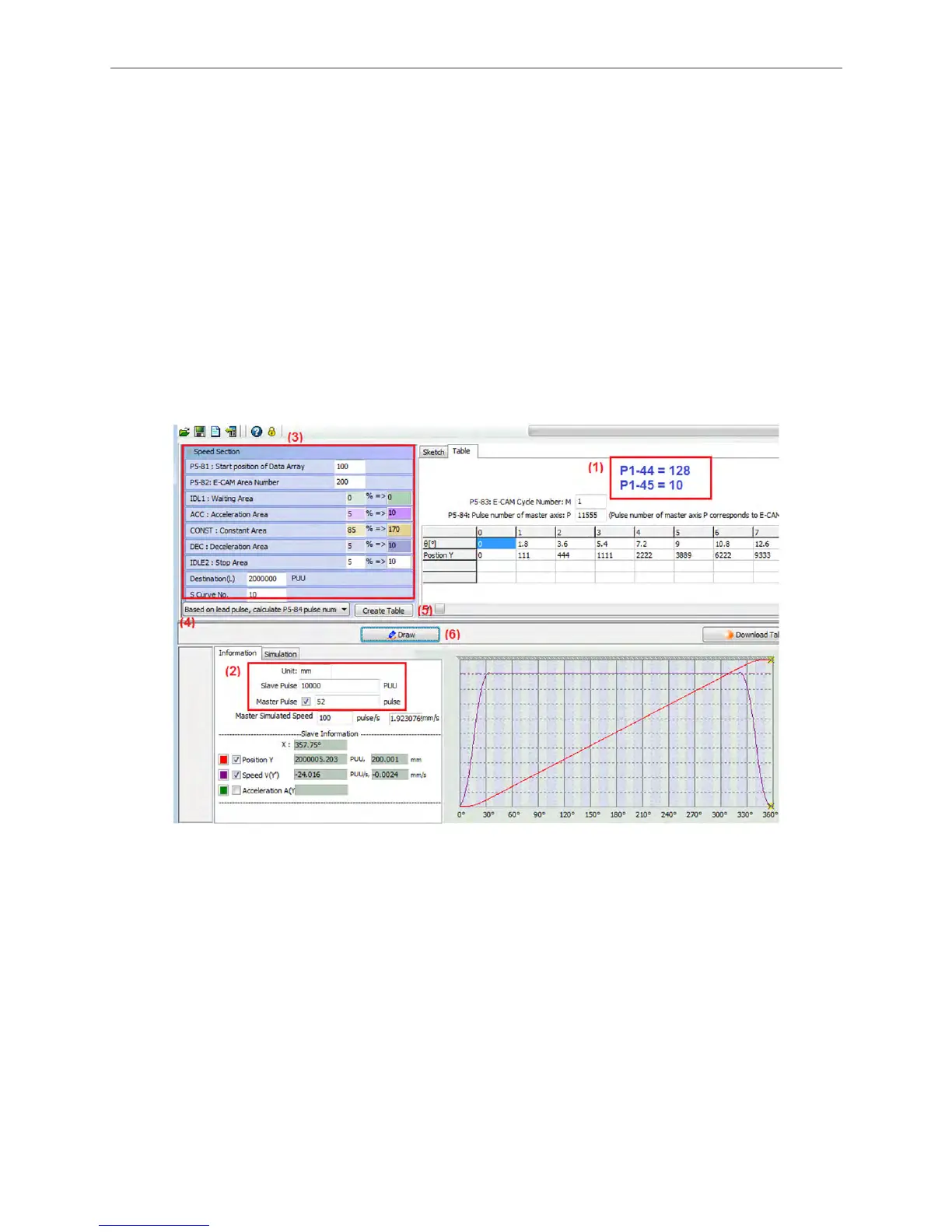

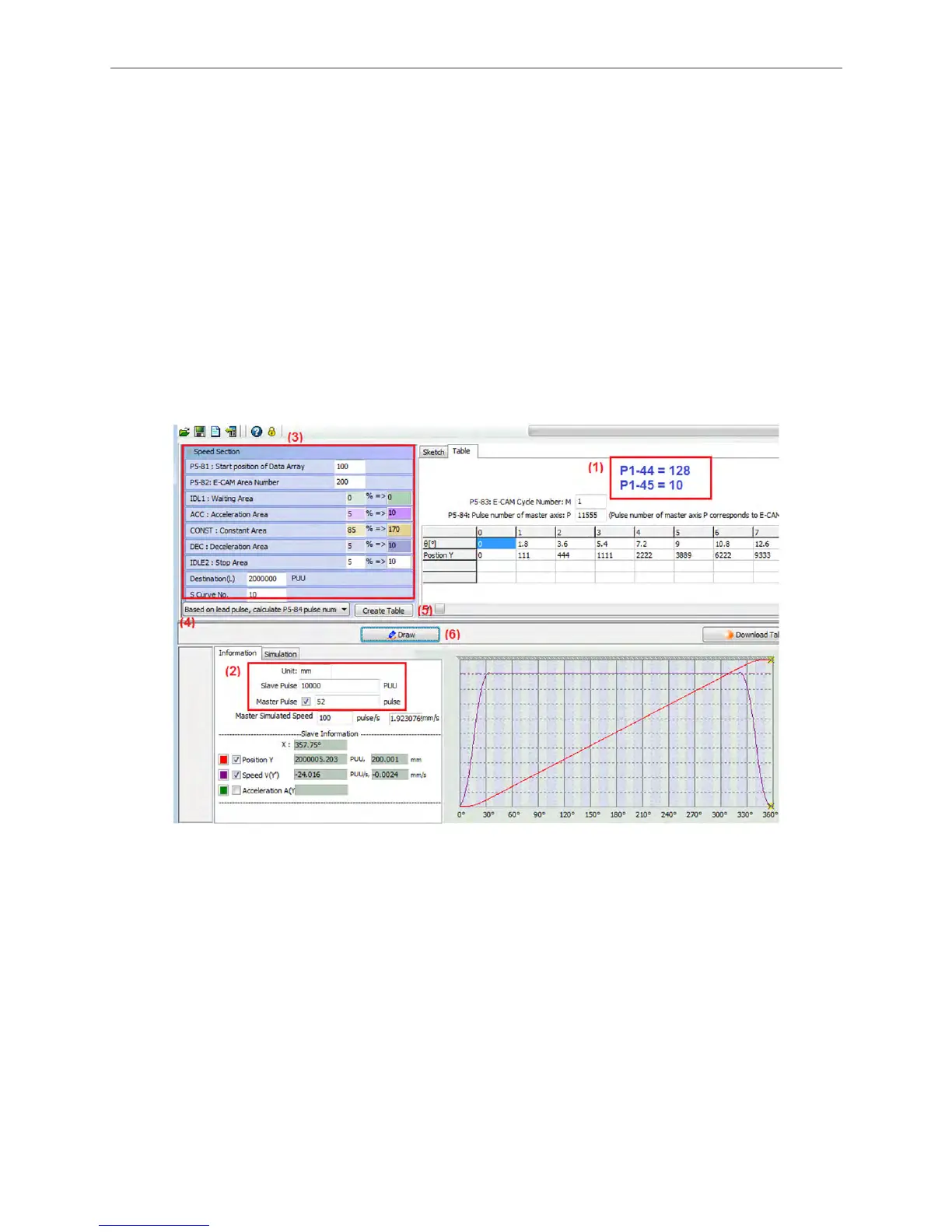

See Figure 2.62 for example of creating E-Cam curve by Speed Fitting Creation.

Figure 2.62 Speed Fitting Creation

1. Set up the E-gear ratio: P1-44 = 128 and P1-45 = 10。

2. Specify the required pulse number when both master and slave axis operate every 1 mm.

The unit of the master axis is pulse; the unit of slave axis is PUU. From Figure 2.61, we

can know that when the master axis operates for 1 mm, the encoder will send 52 pulses;

from calculation above, it takes 10000 PUU for the slave axis to operate every 1 mm.

3. Speed Section. This section allows users to set the proportion of each area, namely

Waiting area, Acceleration Area, Constant Area, Deceleration Area, and Stop Area).

Area proportion will change the speed of the slave axis. The total traveling distance can

be known from the calculation above, which is 2000000 PUU. Total points of this E-Cam

curve can be set in P5-81; P5-82 allows users to specify the address where this E-Cam

Loading...

Loading...