ASDA Series Application Note Application Examples

March, 2015 3-7

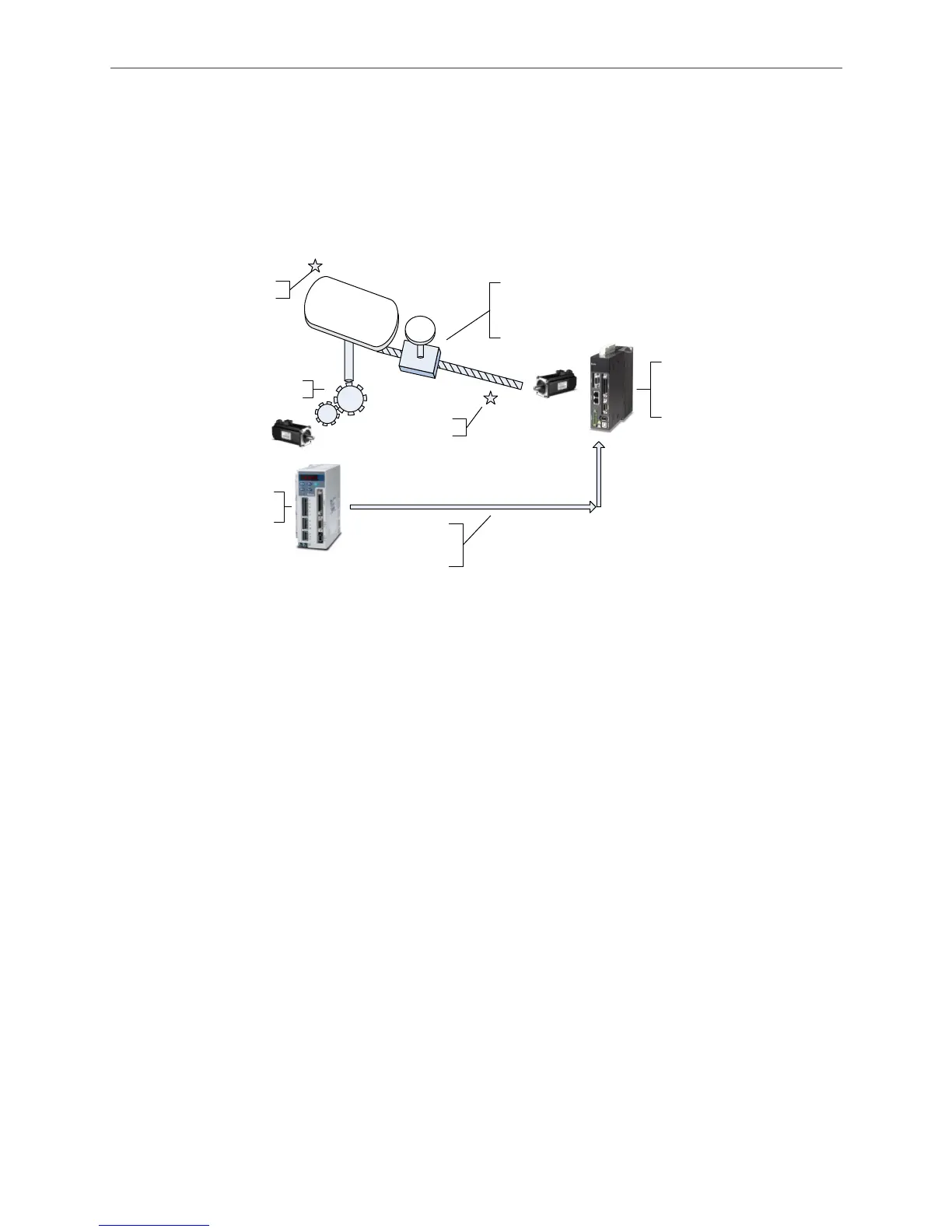

3.1.3.1 System Structure

The master axis used here is an ASDA-A series servo drive and the slave axis used is an

ASDA-A2 series servo drive. There is a decelerator which reduces the speed to 1/5 of the

original speed. The slave axis drives the ball screw via the servo motor. See Figure 3.1.4 system

structure. On master and slave axis, approximation sensors are equipped with the system as the

reference origin for the system.

ASDA-A

series servo drive

Master axis

A2 series servo drive

(slave axis)

1 : 5 decelerator

The platform will

move according to

E-Cam curve from

A2 servo

Pulse signal is sent

to A2 as the master

source signal of the

E-Cam curve

ORG sensor

ORG sensor

operates according to

E-Cam curve

Figure 3.1.4 System Structure

3.1.3.2 Wiring

Regarding the master axis, DI signals that need to connect to the servo drive are DI.SHOM

(search for the origin), DI.ORGP (origin sensor), and DI.CTRG (internal trigger). Among these DI

signals, the function of DI.CTRG is to control the motion of the master axis, making it stop when it

travels one sampling point of the slave axis and allowing the slave axis to complete sampling.

Other signals are for internal use. Since controlling of ON/OFF is not required, actual wiring for

these will be saved, making the I/O wiring easier.

For the slave axis, DI signals that need to connect to the servo drive are mainly DI.SHOM

(search for the origin), DI.ORGP (origin positioning sensor), DI.EV1 (Event 1, for internal trigger),

and DI.CAPTURE (DI7, the trigger point set by the system; setting for register is not required.

When capture function is enabled, this DI will be enabled automatically.) Other DI signals that do

not need to control ON/OFF will be replaced by internal signals without actual wiring.

Loading...

Loading...