ASDA Series Application Note Application Examples

March, 2015 3-123

the distance the position command needs to move. After this PR is triggered, the cutter axis will

move to the target position.

PR

#

7

(I)

PR#46

(I)

PR for cam registration

PR

#1

2

PR#45

(I)

Write

DLY = 0 ms

P5-97 = 0xD

Enable macro D

PR

#12

PR#44

(I)

Write

DLY = 0 ms

P5-95 = 0

PR

#1

2

PR#43

(I)

Write

DLY = 0 ms

P5-93 = 0x0101002E

Setting before enabling macro D

Position

D = 0, S = 1500 rpm

0 PUU, INC

Setup available

forward rate

Figure 3.8.26 PR procedure when E-Cam do positioning again

3.8.3.3 Design of E-Cam Curve

In this system, E-Cam curves for operating film feeding axis and cutter axis have to be set up.

Film feeding axis operates at constant speed according to master axis, thus, its E-Cam curve is

the oblique straight line, which can be done by Manually create a table in E-CAM Editor. E-Cam

curve of cutter axis is the curve of flying shear, which can be done by Rotary Shear– W/O

Sealing Zone or macro command (if it has constant speed area).

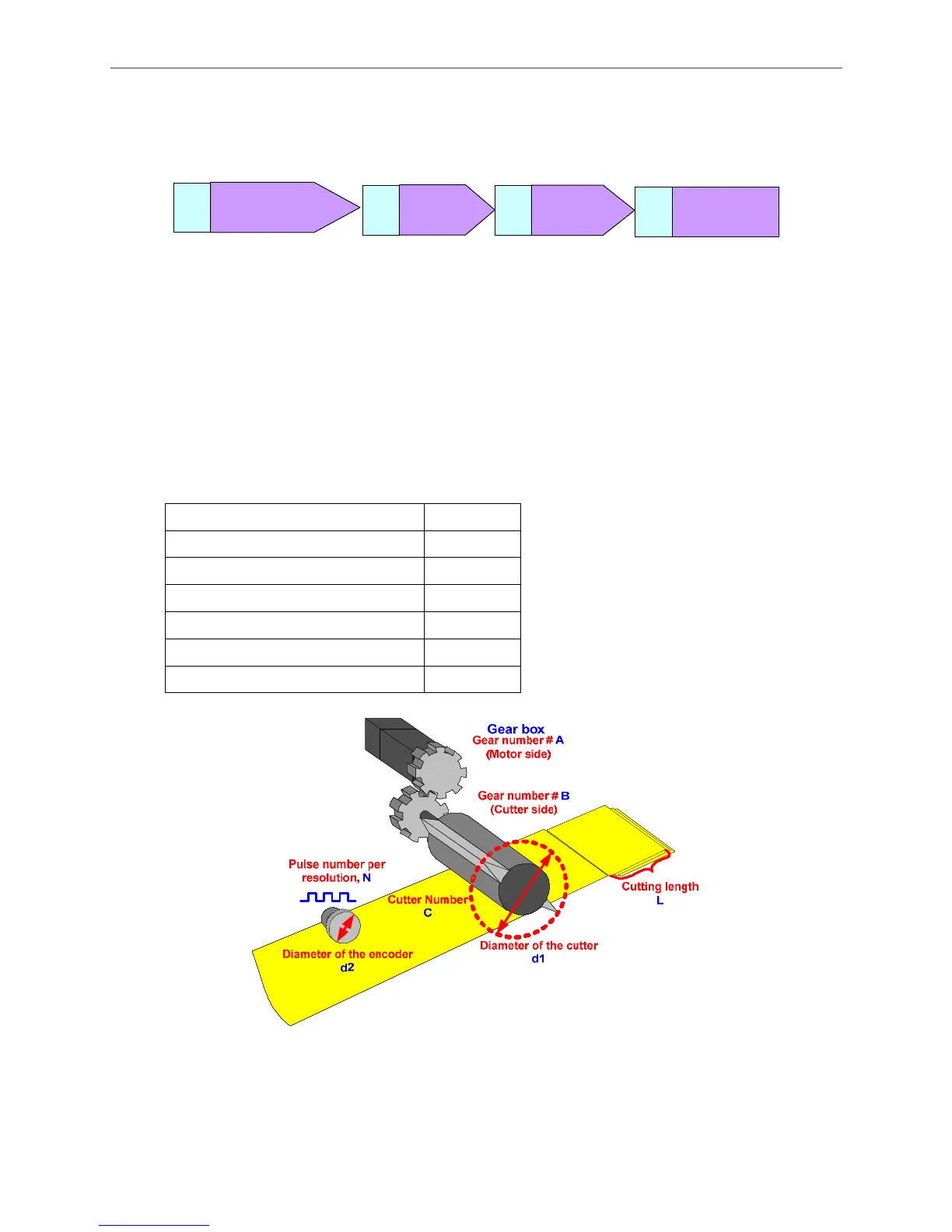

Followings are the mechanism specification:

Figure 3.8.27 Mechanism specification

Gear number at motor side # (A) 5

Gear number at cutter side # (B) 5

Diameter of the encoder (d2) 20 mm

Pulse number per resolution (N) 10000

Cutter number (C) 1

Diameter of the cutter (d1) 200 mm

Cutting length (L) 500 mm

Loading...

Loading...