Introduction of E-Cam Operation ASDA Series Application Note

2-42 March, 2015

2.7 E-Cam Setting Example

(This example only illustrates the basic setting of E-Cam, real application example can be found

in Chapter 3 of this application note.)

2.7.1 Creating an E-Cam Curve

In this example, Speed Fitting Creation in ASDA-Soft is used to create a simple E-Cam curve.

For details about ways to create E-Cam curves, please refer to ASDA-Soft user manual.

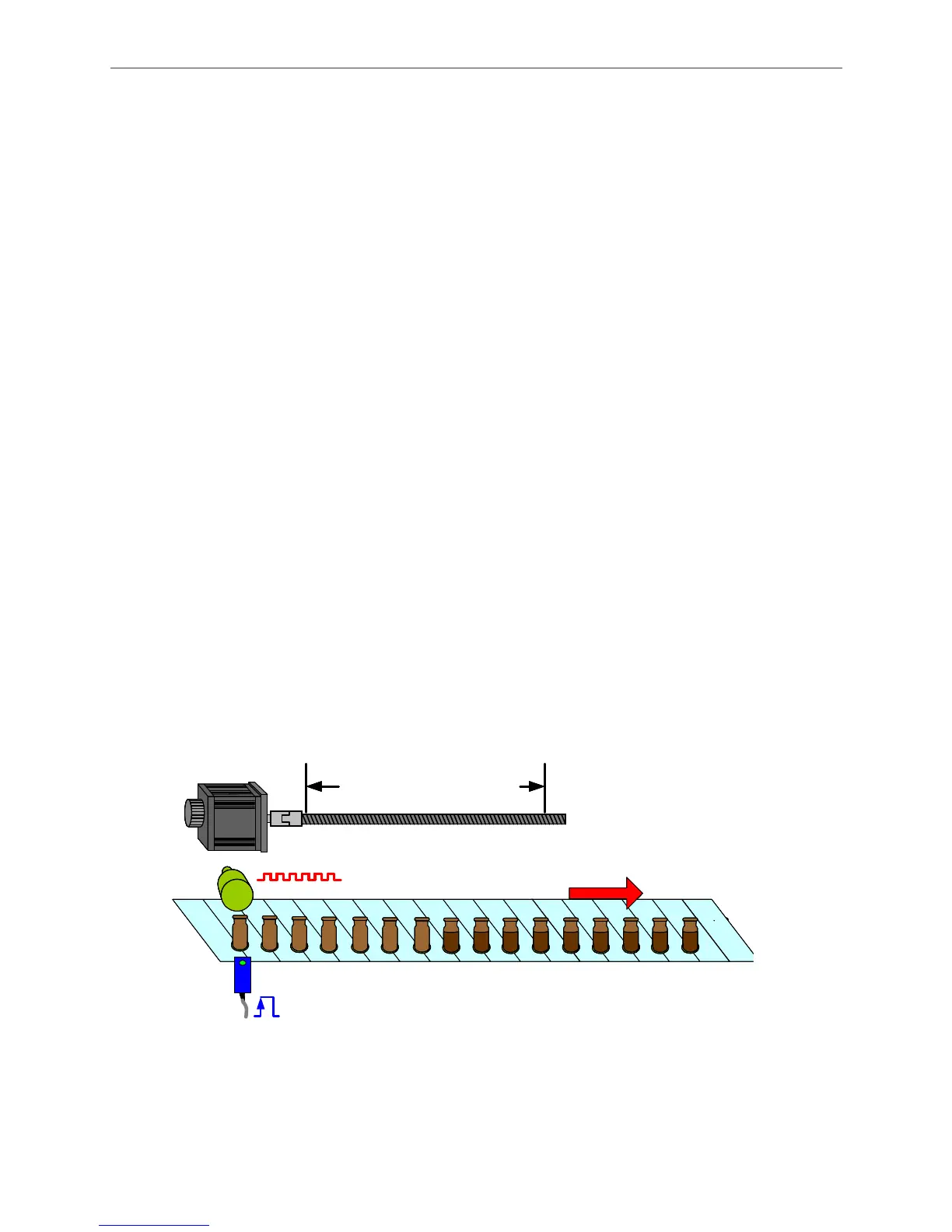

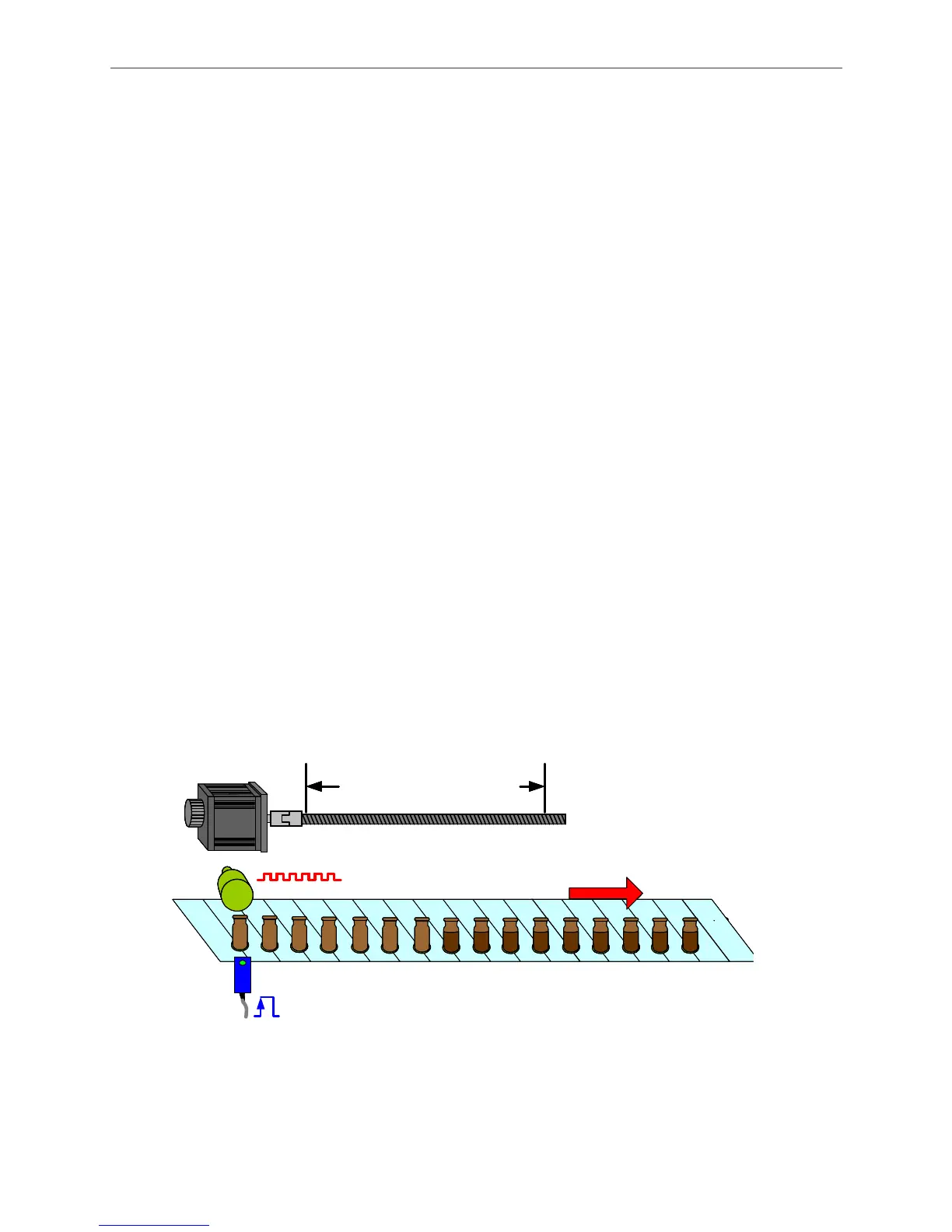

The first step is to figure out the motion of the slave axis and mechanical specifications. Then,

translate the motion into an E-Cam curve. Please note that the mechanical specifications might

change the scale of the curve. The mechanical motion and specification below is also shown in

Figure 2.61:

The master axis is a material feeding axis that operates with a constant speed. And there is an

encoder equipped on this axis. When material feeding axis moves, it will drive the encoder to

operate. The traveling distance of the material feeding axis is the total rotating distance of the

encoder. Pulses sent by the encoder are directly transmitted to CN1 of the slave axis as the

source of the master axis. The encoder will send 52 pulses every 1 mm and this is the

specification of the encoder.

The slave axis is a ball screw which pitch is 10 mm and total length is slightly longer than 200

mm. After E-Cam is engaged, the position of the slave axis operates from 0 mm to 200 mm. After

reaching the position, E-Cam will disengage. Then, a PR position command will be triggered to

take the slave axis back to position 0. Then, it uses the CAP function triggered by the sensor to

make E-Cam engaged. The E-gear ratio setting of the slave axis is P1-44 = 128 and P1-45 = 10,

which means it takes 100000 PUU for motor of the slave axis to make one full rotation.

Slave Axis

Master Axis

Pulse No. of the Encoder: 52 pulse/mm

Lead of the carrier: 200 mm

Pitch of the ball screw: 10 mm

DI 7

Use capture function

to engage E-Cam

Figure 2.61 Mechanical Specification

From the information above, the required setting value for creating an E-Cam curve can be

known.

Loading...

Loading...