ASDA Series Application Note Application Examples

March, 2015 3-105

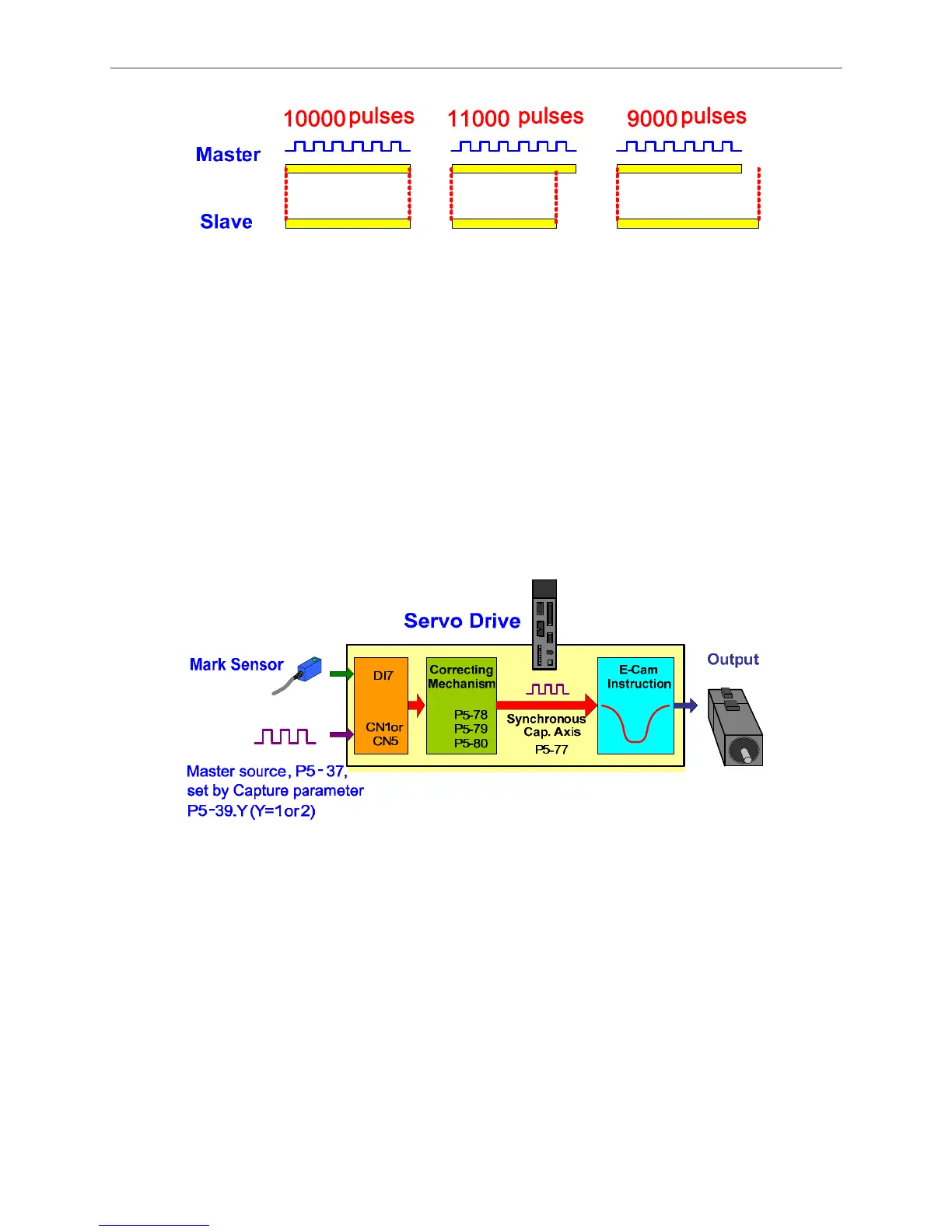

Figure 3.8.4 Relation of the Pulse from the Master Axis and the Cutting Length

In order to solve the problem of abnormal pulse sent by master axis, the pulse number between

two marks can be regarded as the basis. And the difference between the actual receiving pulses

of two marks can be the basis for adjusting the cutting length. See figure 3.8.5. After comparing

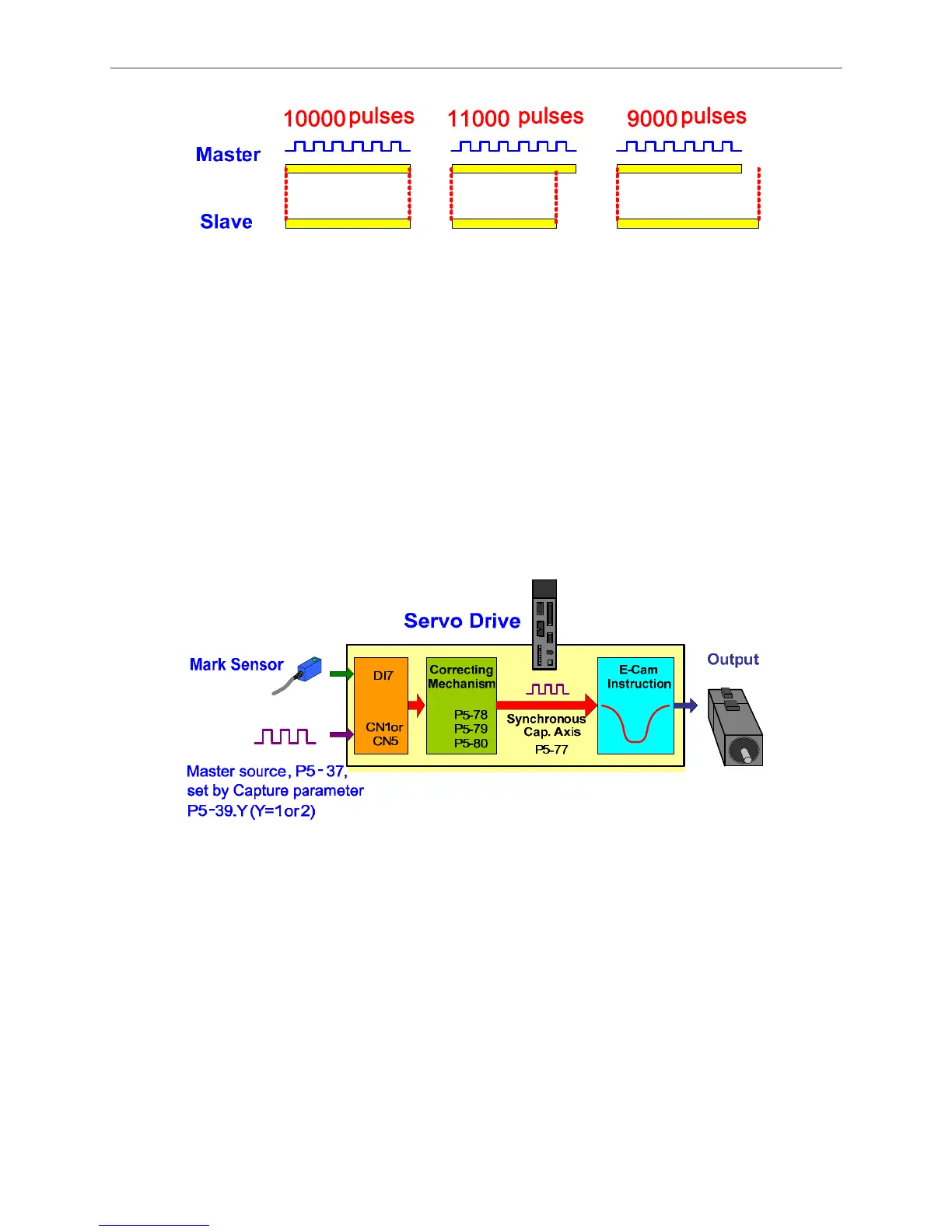

the pulse number triggered by DI7 for two times and the pulse number set by master axis, the

differences will be adjusted by correcting mechanism. The adjusted signal is the synchronous

capture axis. Use the adjusted synchronous capture axis as the master axis to drive the

camshaft. And the pulse of master axis corresponded by the camshaft will be adjusted by

synchronous capture axis. Therefore, even when the pulse number of master axis is incorrect,

the camshaft still can do the adjustment in time.

Figure 3.8.5 Synchronous Capture Axis

If the user wants to use synchronous capture axis, signal of the mark sensor must be input

by DI7 of CN1 of ASDA-A2 Servo;

The source of master axis of E-cam must set to 5. This setting is to select synchronous

capture axis as the source of master axis;

The engaging condition must set to 2 and use capturing to control the engaging time;

The pulse number between two marks must be set in P5-78. The setting of P5-78 must be

correct, or the system has no basis for comparison. Generally, P5-78 = P5-84. If P5-83 = 1,

then the distance between two marks is the distance the cam curve travels for a cycle. See

figure 3.8.6. In every cycle, the actual pulse number output by master axis between two

Loading...

Loading...