ASDA Series Application Note Application Examples

March, 2015 3-107

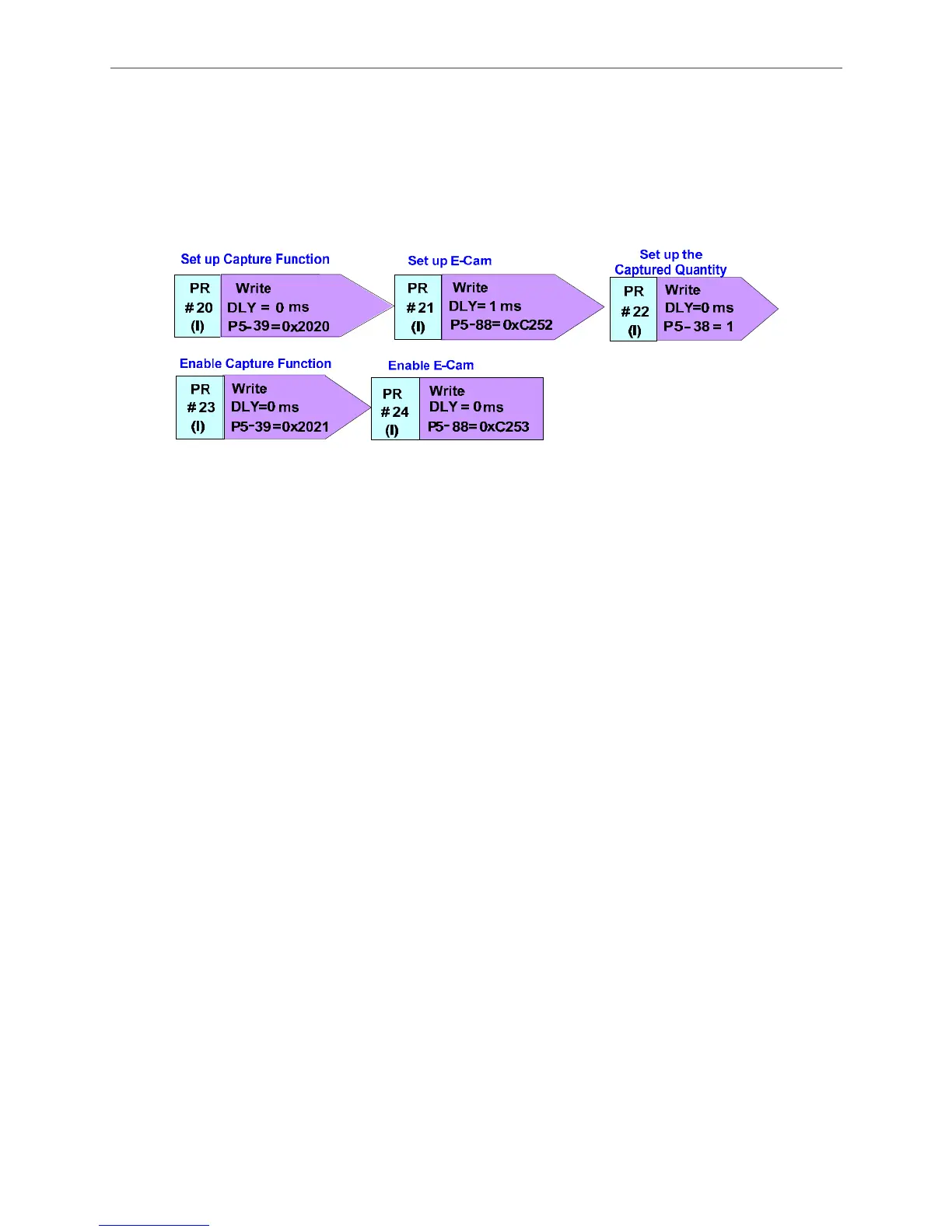

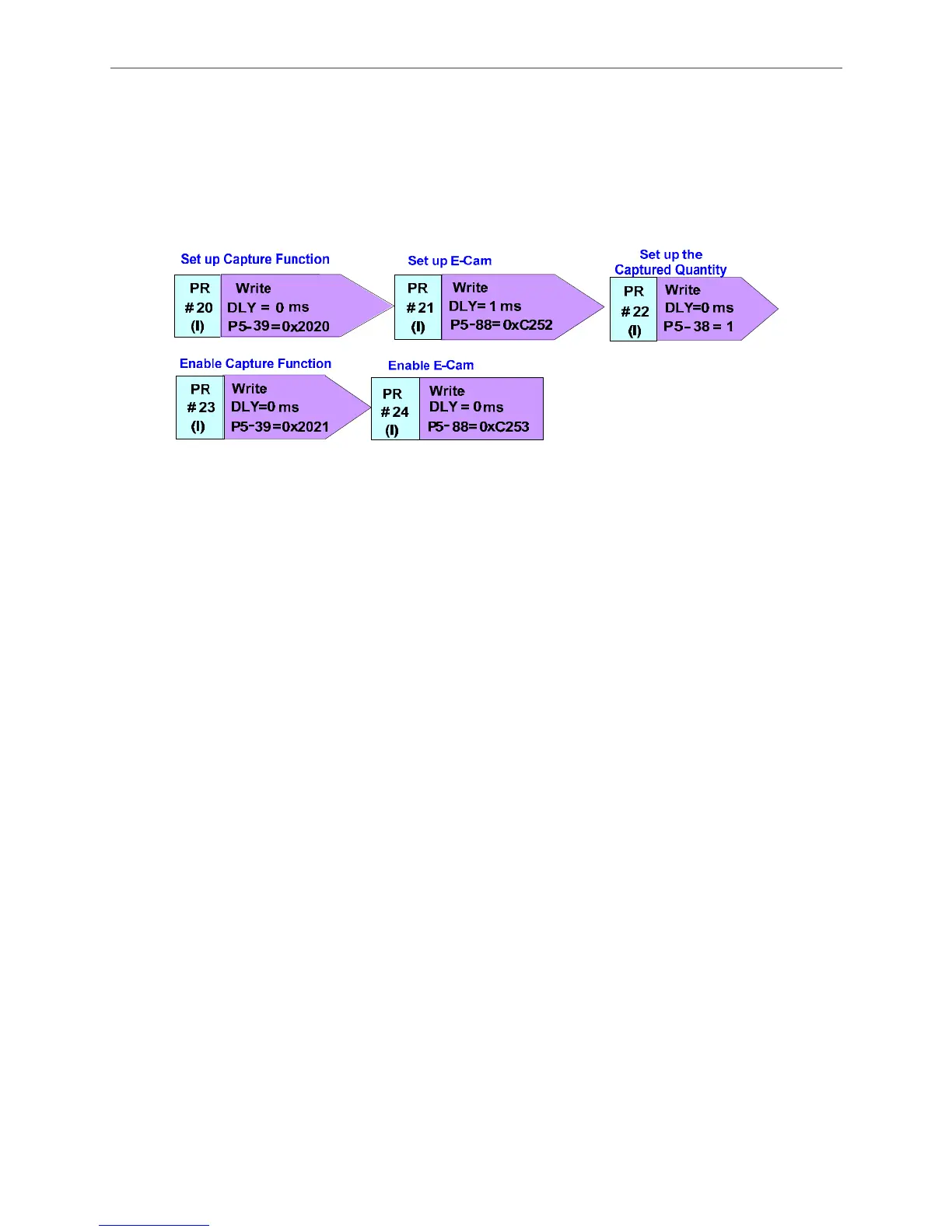

PR#22: P5-38 is to set up the captured quantity. The capture function captures one data every

cycle. Therefore, P5-38 = 1.

PR#23: Enable Capture Function, P5-39.X = 1.

PR#24: Enable E-Cam, P5-88.X1 = 1.

Figure 3.8.7 PR Setting of Synchronous Capture Axis Application on Cam

Cam Positioning

The application of cam positioning is illustrated in Figure 3.8.8. Users need to set the target

position first. The system will follow the setting and adjust it according to the difference between

the actual position and the setting one by calculating every cycle. The target position, which is

where the sensor installed, is set up by the pulse number of master axis. Take the application on

wrapping film positioning as the example. When the sensor detects the mark of the wrapping film,

the signal will be sent back to the drive. The system will check if the master axis is in the setting

position and calculate the difference of the camshaft so as to do the adjustment. For instance, if

the cam needs 36000 pulses to travel a cycle (e.g. P5-83 = 1, P5-84 = 36000), and the master

axis has 19000 pulses when setting positioning. Also, from the E-cam curve, the corresponding

position which is 9000 PUU can be known. When reading the mark, if the pulse number of

master axis is 17000, the system knows it has 2000 pulses difference from the positioning target,

the system will therefore calculate the error, 2000 pulses. With the error number calculated from

the cam curve, the correction rate which is 500 PUU can be known. This is called cam

positioning. Therefore, with the correction rate, positioning will be completed by overlap

commands.

Loading...

Loading...