ASDA Series Application Note Chapter 4 Application Techniques

March, 2015

4-15

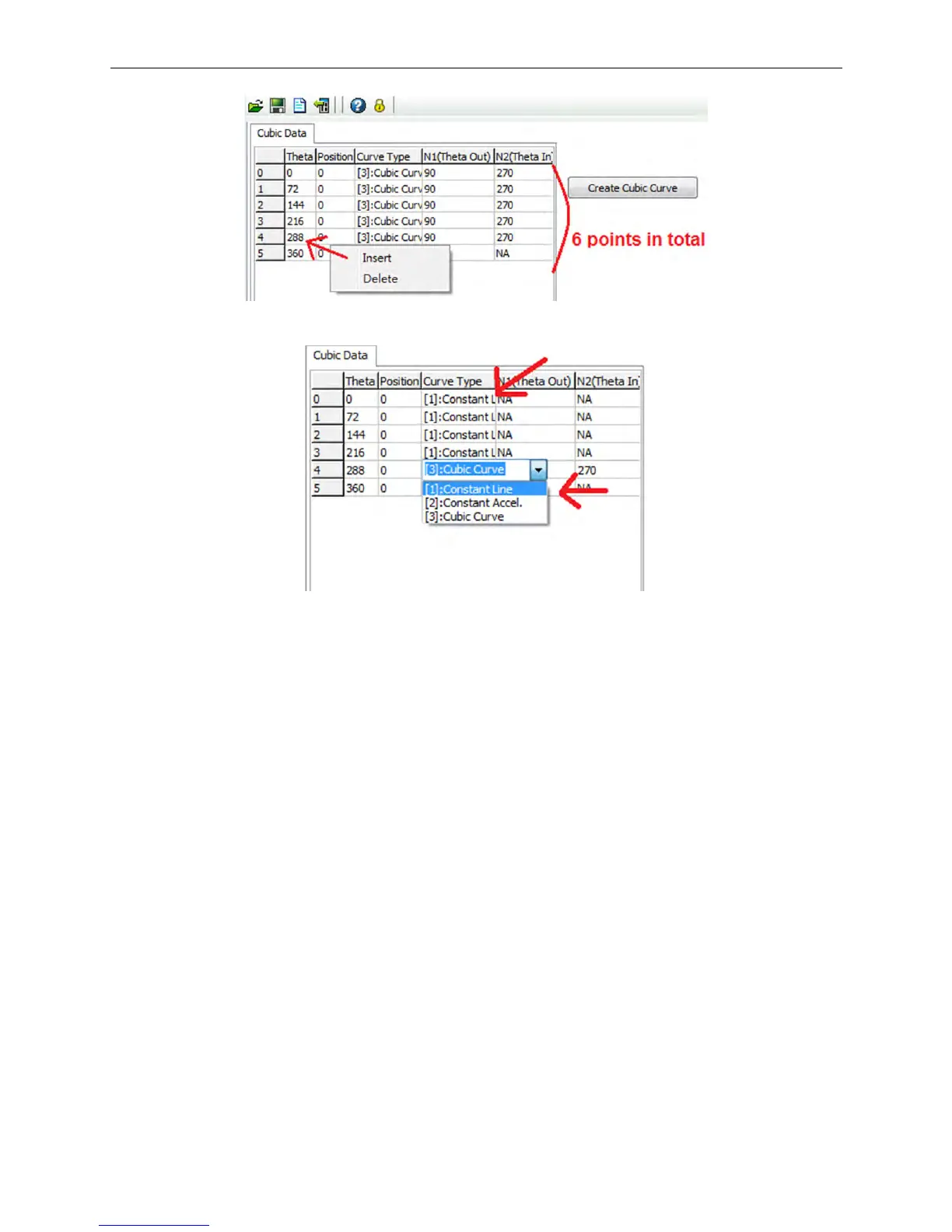

Figure 4.2.14 Total points = measuring points + origin

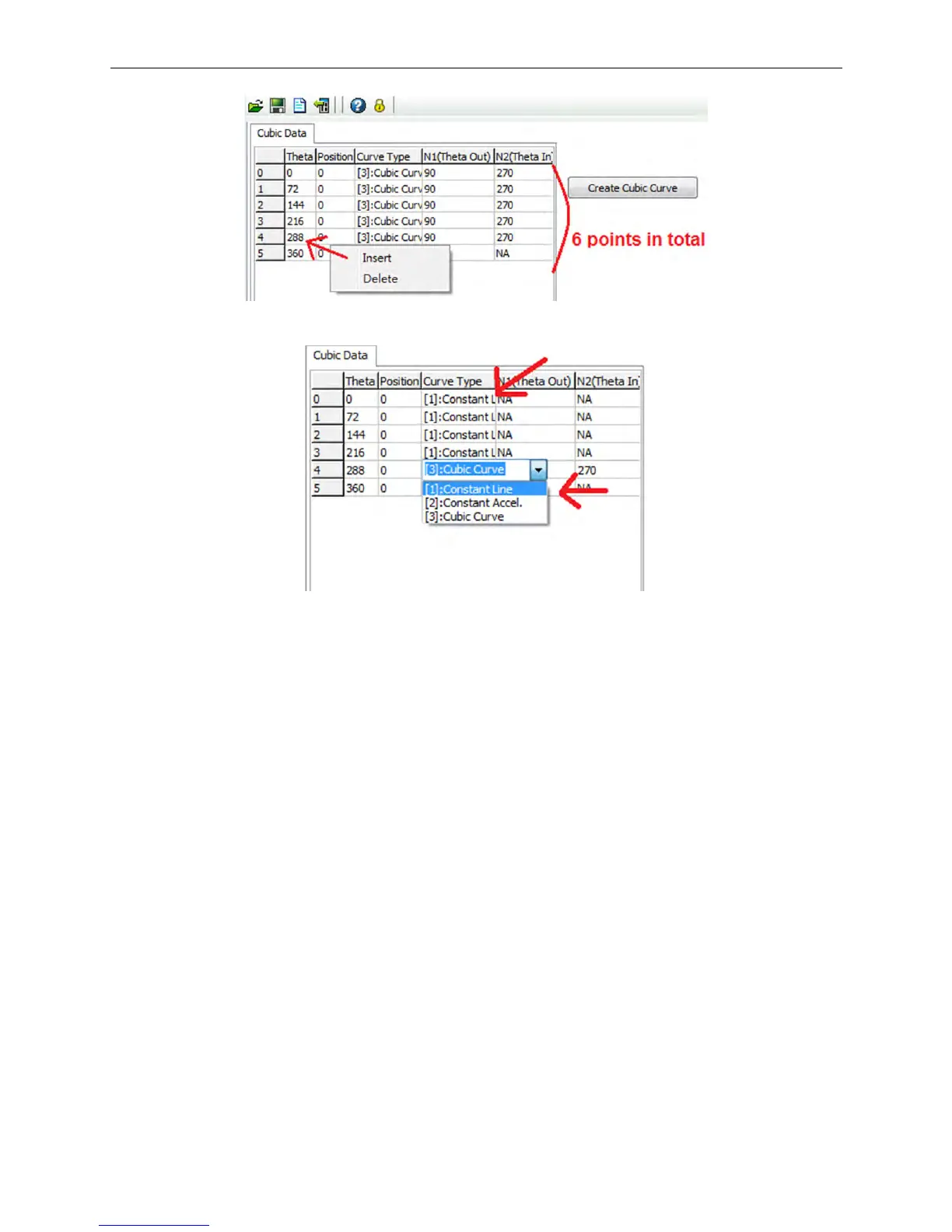

Figure 4.2.15 Set Curve Type of Every Angle to [1]: constant line

4. Please refer to Figure 4.2.9 and Figure 4.2.10. Calculate the angle of the master axis and

take 0.1 mm/pulse as the basis of command resolution.

0 mm 0 Pulse 0° 0 PUU

102 mm 1020 pulse 360 * 1020 / 5000=73.44° 1000000 PUU

208 mm 2080 pulse 360 * 2080 / 5000=149.76° 2000000 PUU

298 mm 2980 pulse 360 * 2980 / 5000=214.56° 3000000 PUU

404 mm 4040 pulse 360 * 4040 / 5000=290.88° 4000000 PUU

502 mm 5020 pulse 360 * 5020 / 5000=361.44° 5000000 PUU

As the last one has exceeded 360°, edit the data and keep it within the range (360°):

500 mm 5000 pulse 360° 5000000 * 5000 / 5020 = 4980080 PUU

5. Fill in the data mentioned above. Then, set Sample ang. (sampling angle) to 1°. Click on

Create Cubic Curve Download table

Burn Table Data. This will be the curve specially

made for this lead screw.

Loading...

Loading...