5 Categories and Use of Basic Application Instructions

DVP-PM Operation Instruction

5-20

API Mnemonic Function

07

WDT P Watchdog Timer Refresh

Controllers

20PM 10PM

OP Descriptions Program Steps

N/A

No operand. No contact to drive the instruction is required

WDT, WDTP: 1 step

Explanations:

1. WDT instruction can be used to reset the Watch Dog Timer. If the PLC scan time (from address 0 to END or

FEND instruction) is more than 200ms, the ERROR LED will flash. In this case, users have to turn the power

OFF and then ON to clear the fault. PLC will determine the status of RUN/STOP according to RUN/STOP

switch. If there is no RUN/STOP switch, PLC will return to STOP status automatically.

2. Time to use WDT:

a) When error occur in PLC system.

b) When the scan time of the program exceeds the WDT value in D1000. It can be modified by using the following

two methods.

i. Use WDT instruction

T1

T2

STEP0 END(FEND)

WDT

ii. Use the set value in D1000 (Default: 200ms) to change the time for watchdog.

Points to note:

1. When the WDT instruction is used it will operate on every program scan as long as its input condition has been

made. To force the WDT instruction to operate for only ONE scan, users have to use the pulse (P) format of

the WDT instruction, i.e. WDTP.

2. The watchdog timer has a default setting of 200ms. This time limit can be customized to users requirement by

editing the content in D1000, the wathdog timer register.

Program example:

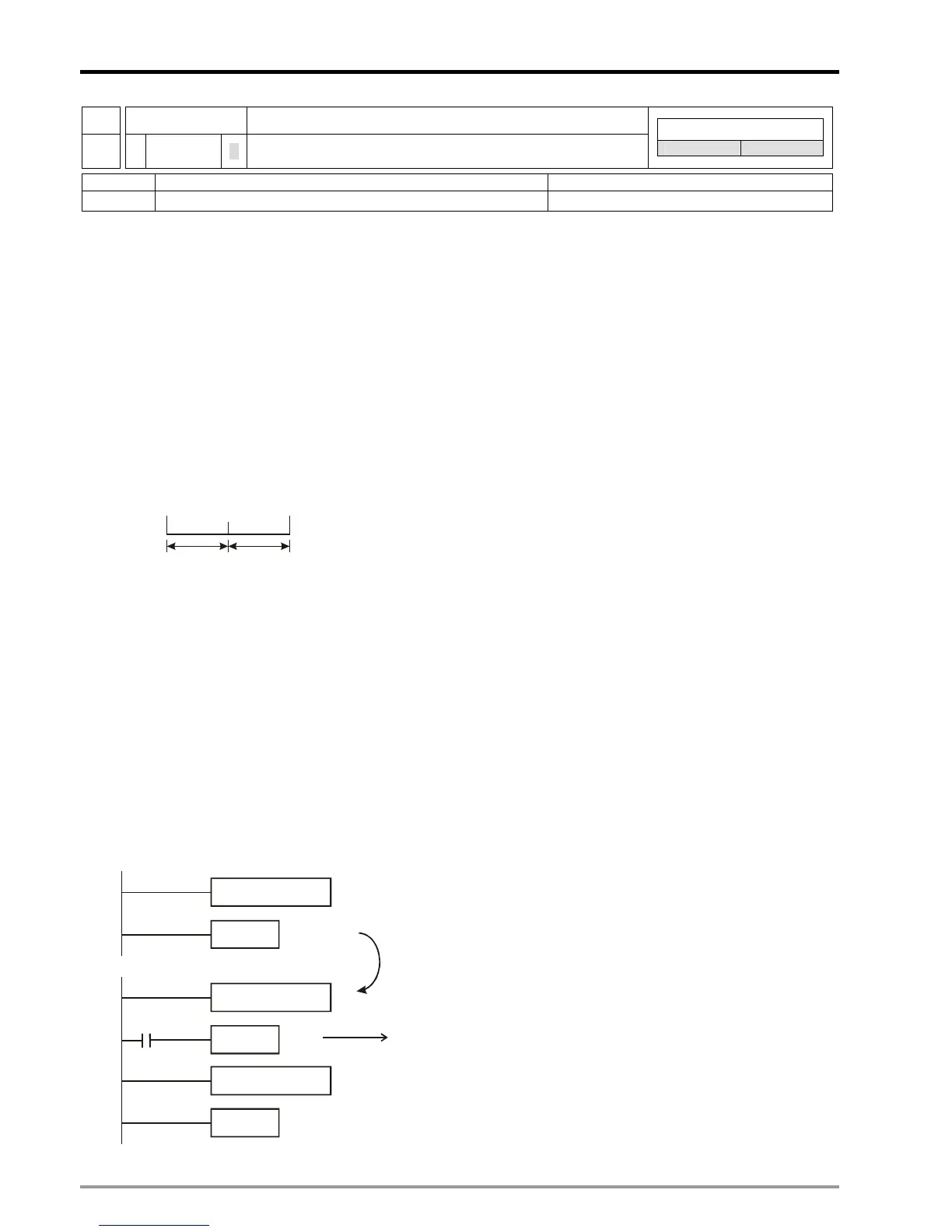

If the program scan time is over 300ms, users can divide the program into 2 parts. Insert the WDT instruction in

between, making scan time of the first half and second half of the program being less than 200ms.

X0

END

END

WDT

300ms program

150ms program

150ms program

Dividing the program to two parts

so that both parts scan time are

less than 200ms.

Watchdog timer reset

Loading...

Loading...