9 Electrical CAM

DVP-PM Application Manual

9-63

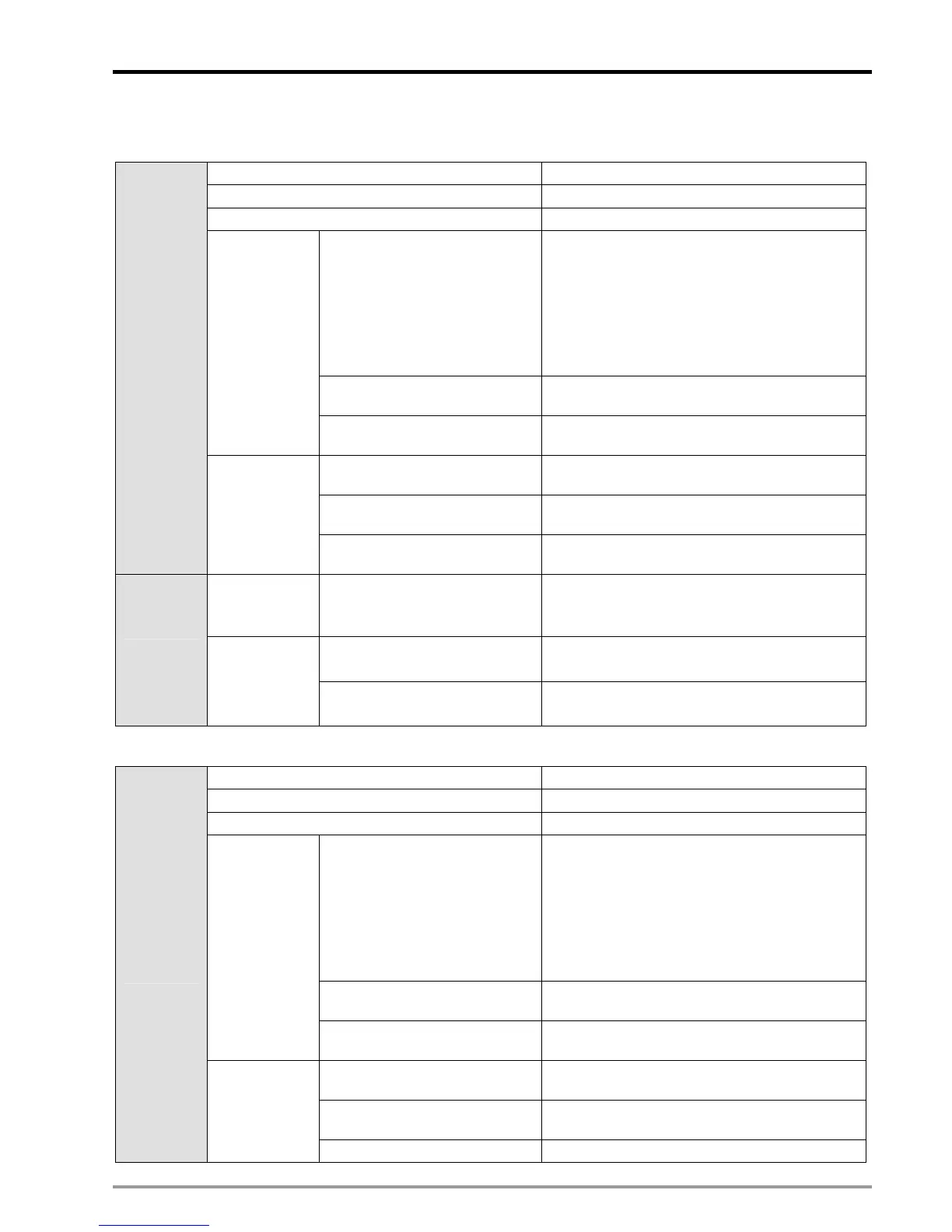

Here are 2 examples of obtainng the settings of Master and Slave

Example 1

Rounds per layer N1 = 10

Total rounds of winding N2 = 80

Coil spacing (mm) D = 0.2

Mechanism parameter

(mm/revolution)

There is no actual moving distance of Master

because winding shaft is directly driven by

signals. The winding principle is that Slave

moves certain distance when Master rotates a

round, therefore mechanism parameter of

Master can be regarded the same as that of

Slave.

A

Master

= A

Slave

Servo parameter

(pulses/revolution)

B

Master

= 3600

Winding shaft

(Master/Y

axis)

Mechanical parameter

(mm/pulses)

C

Master

= A

Master

/B

Master

Mechanism parameter

(mm/revolution)

A

Slave

= 10

Servo parameter

(pulses/revolution)

B

Slave

= 10000

Input

parameters

Coil shaft

(Slave/X axis)

Mechanical parameter

(mm/pulses)

C

Slave

= A

Slave

/B

Slave

Winding shaft

(Master/Y

axis)

Length of single speed

positioning (pulses)

=N2 x B

Master=

= 80 x 3600 = 288000

Master

Max

(pulses)

=2 x N1 x B

Master

= 2 x 10 x 3600 = 72000

“2” indicates double layer winding

Settings

Coil shaft

(Slave/X axis)

Slave

max

(pulses)

=N1 x D/C

Slave

= 10 x 0.2 / (0.1/100)

=2000

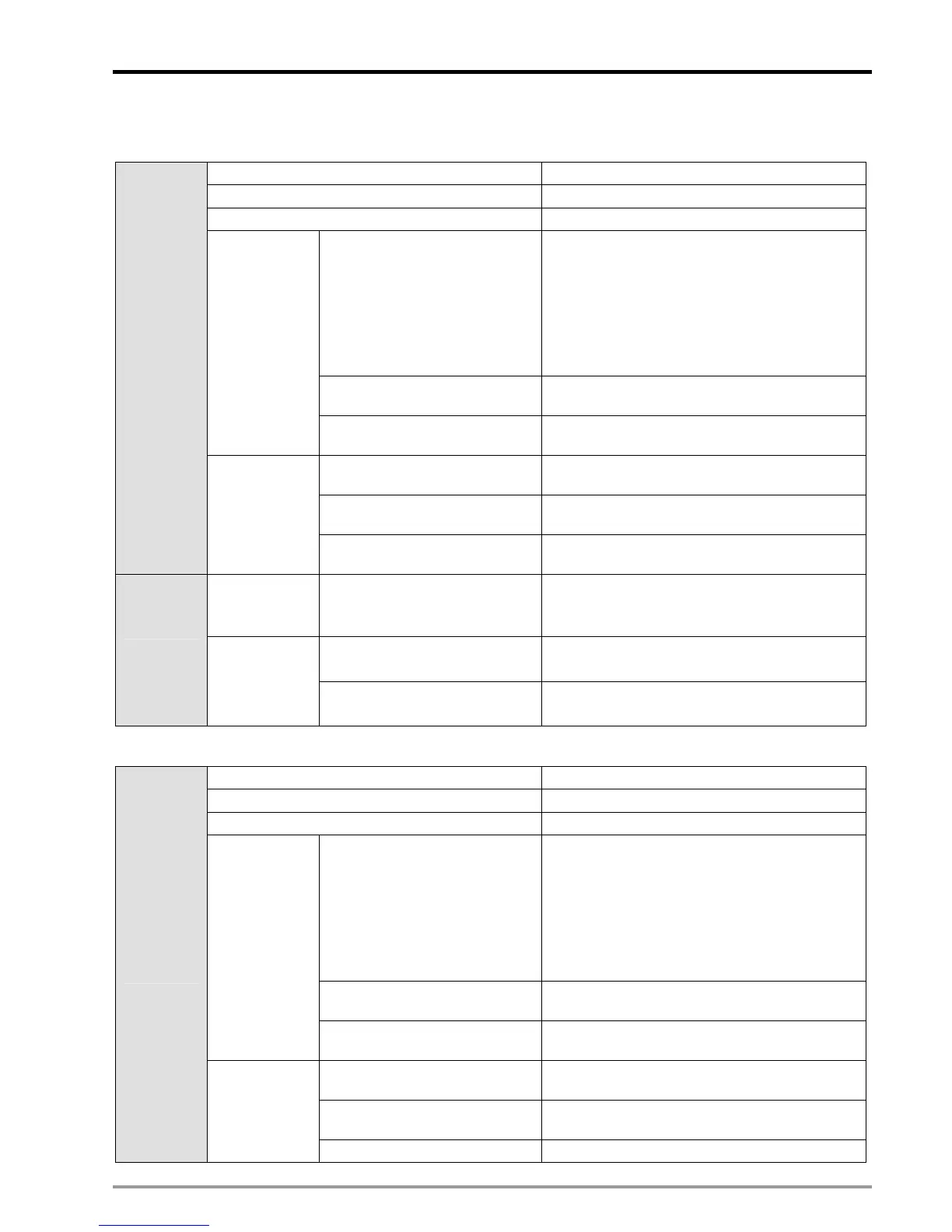

Example 2

Rounds per layer N1 = 20

Total rounds of winding N2 = 100

Coil spacing (mm) D = 0.3

Mechanism parameter

(mm/revolution)

There is no actual moving distance of Master

because winding shaft is directly driven by

signals. The winding principle is that Slave

moves certain distance when Master rotates a

round, therefore mechanism parameter of

Master can be regarded the same as that of

Slave.

A

Master

= A

Slave

Servo parameter

(pulses/revolution)

B

Master

= 3600

Winding shaft

(Master/Y

axis)

Mechanical parameter

(mm/pulses)

C

Master

= A

Master

/B

Master

Mechanism parameter

(mm/revolution)

A

Slave

= 10

Servo parameter

(pulses/revolution)

B

Slave

= 10000

Input

parameters

Coil shaft

(Slave/X axis)

Mechanical parameter

C

Slave

= A

Slave

/B

Slave

Loading...

Loading...