Mechanical Specifications

53

Additional Design Recommendations

The following list provides additional design guidance with respect to thermal management in

applications with operating temperatures at the high end or beyond the specified standard ambient

temperature range.

Providing air movement will improve heat dissipation.

The host PCB plays a large part in dissipating the heat generated by the module. A large

copper plane located under the Digi Connect ME 9210 is soldered to the module’s mounting

tabs will improve the heat dissipation capabilities of the PCB.

If the design allows, added buried PCB planes will also improve heat dissipation. The copper

planes create a larger surface to spread the heat into the surrounding environment.

Adding a thermal pad or thermal compound, such as Sil-Pad

®

, Gap Pad

®

or Gap Filler

products made by the Bergquist Company (www.bergquistcompany.com), between the host

PCB and the underside of the module will significantly increase the thermal transfer between

the module’s enclosure and the host PCB. Limit the fill area to the folded metal portion of the

module’s underside.

Mechanical Specifications

Bar Code

The 50m PN is code 3 of 9 (39) and the MAC is code 128. All scanners are set up so if they read

code 3 of 9 they will automatically read 128. The reason for the two different code types is to

maximize the size of the bars within a given space to improved readability.

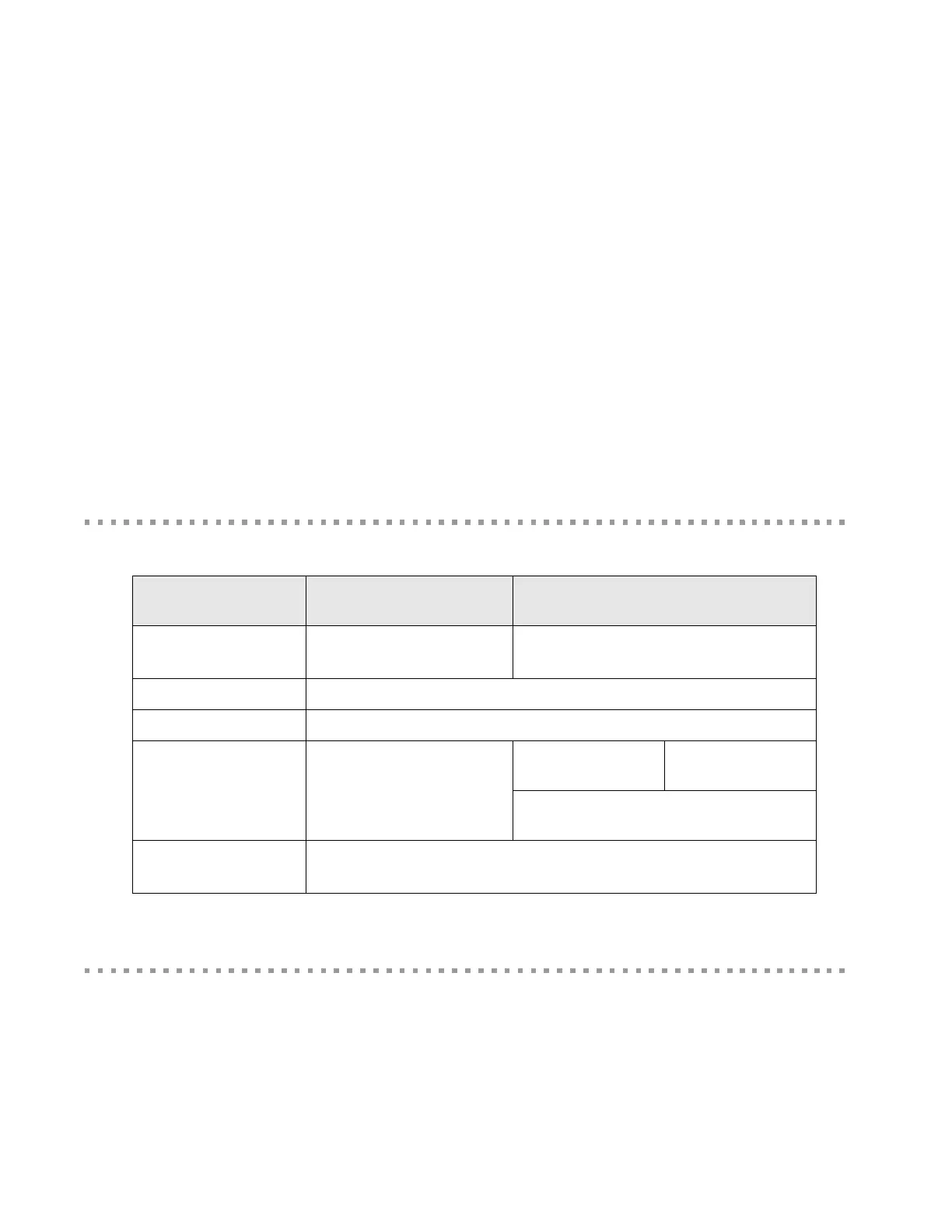

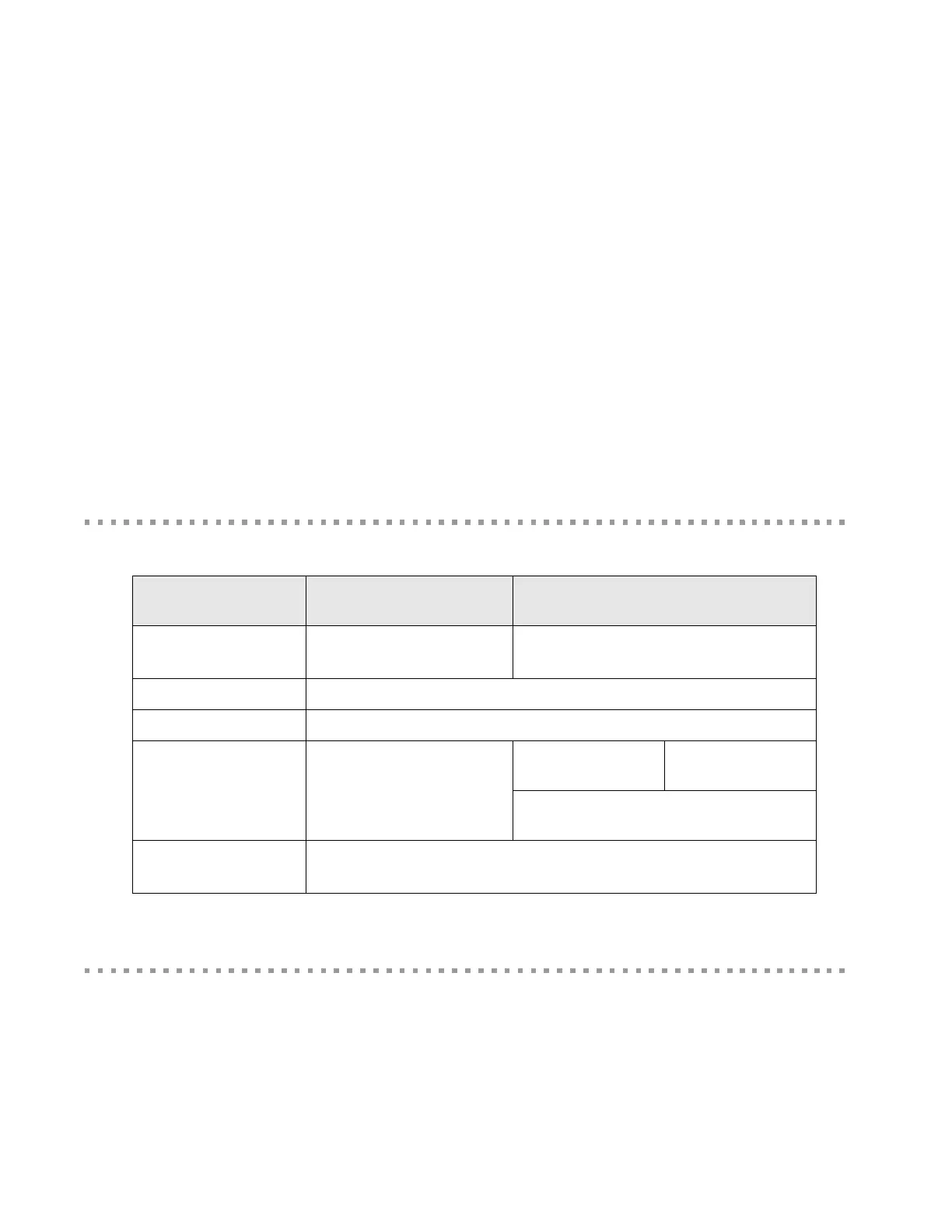

Dimensions

Digi Connect

ME

Digi Connect

Wi-ME

Length

1.445 in.

(36.703 mm)

1.85 in

(46.99 mm)

Width 0.75 in. (19.05 mm)

Height 0.854 in. (21.69 mm)

Weight

.616oz.

17.463g

.696 oz.

19.731 g.

Antenna:.408 oz.

11.567 g

Total: 1.104 oz.

31.298 g

Device/serial

interface connector

20-pin micro header (10-pin double row) with .05-inch (1.27-mm) pitch (Samtec

P/N FTS-110-01-F-DV-TR or similar). Positions 3 through 6 are removed.

Loading...

Loading...