G643 (E) Service Manual Chapter 3. Engine Mechanical System 98

IMPORTANT: Each connecting rod and bearing

cap should be marked, beginning at the front of

the engine. Cylinders 1, 3, and 5 are the right

bank and 2, 4, and 6 are the left bank (when

viewed from the front of the engine). The

numbers on the connecting rod and bearing cap

must be on the same side when installed in the

cylinder bore. If a connecting rod is ever

transposed from one block or cylinder to

another, new connecting rod bearings should be

fitted and the connecting rod should be

numbered to correspond with the new cylinder

number.

NOTICE: Refer to “Notice” on page 1.

5. Connecting rod cap with bearing insert and nut.

Tighten

• Connecting rod bolt nuts to 27 Nm (20 lbft.).

• Connecting rod bolt nuts an additional 70° using

J 36660.

Measure

• Connecting rod side clearance as outlined

previously.

Balance Shaft Installation

Figures 12-72 through 12-76

NOTICE: Refer to “Notice” on page 1.

Tools Required:

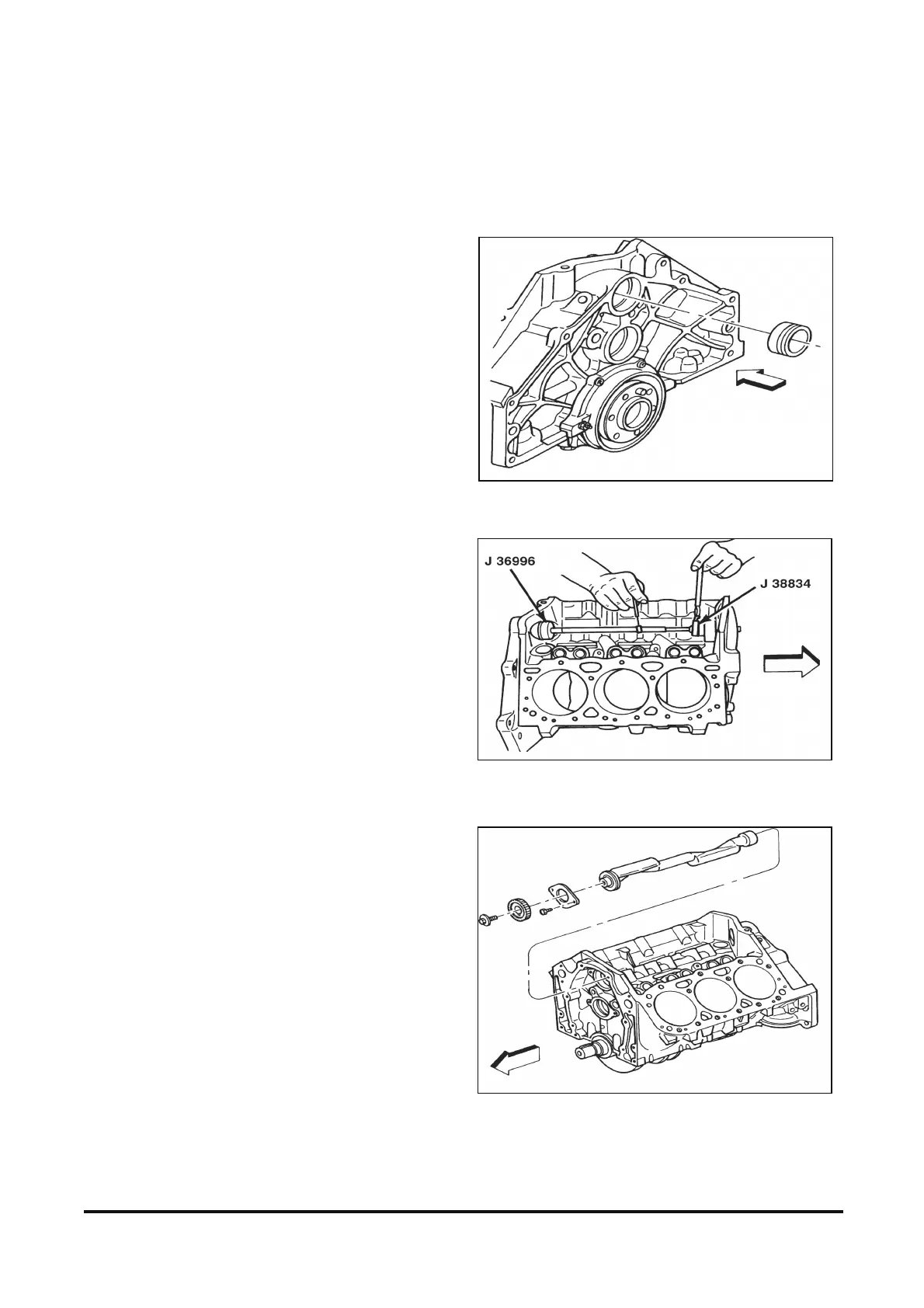

J 38834 Balance Shaft Bearing Service Kit

J 36996 Balance Shaft Installer

J 8092 Driver Handle

J 36660 Torque Angle Meter

Install or Connect

1. Balance shaft rear bearing using J 38834

(figures 12-72 and 12-73).

2. Balance shaft into block using J 36996 and

J 8092 (figure 12-74).

A. Dip the front balance shaft bearing into clean

engine oil before assembly.

B. Retaining ring on balance shaft front bearing

must be seated on case.

3. Install balance shaft bearing retainer and bolts.

Tighten

• Balance shaft retainer bolts to 14 N•m (124 lb.in.).

4. Balance shaft driven gear (2) and bolt (1).

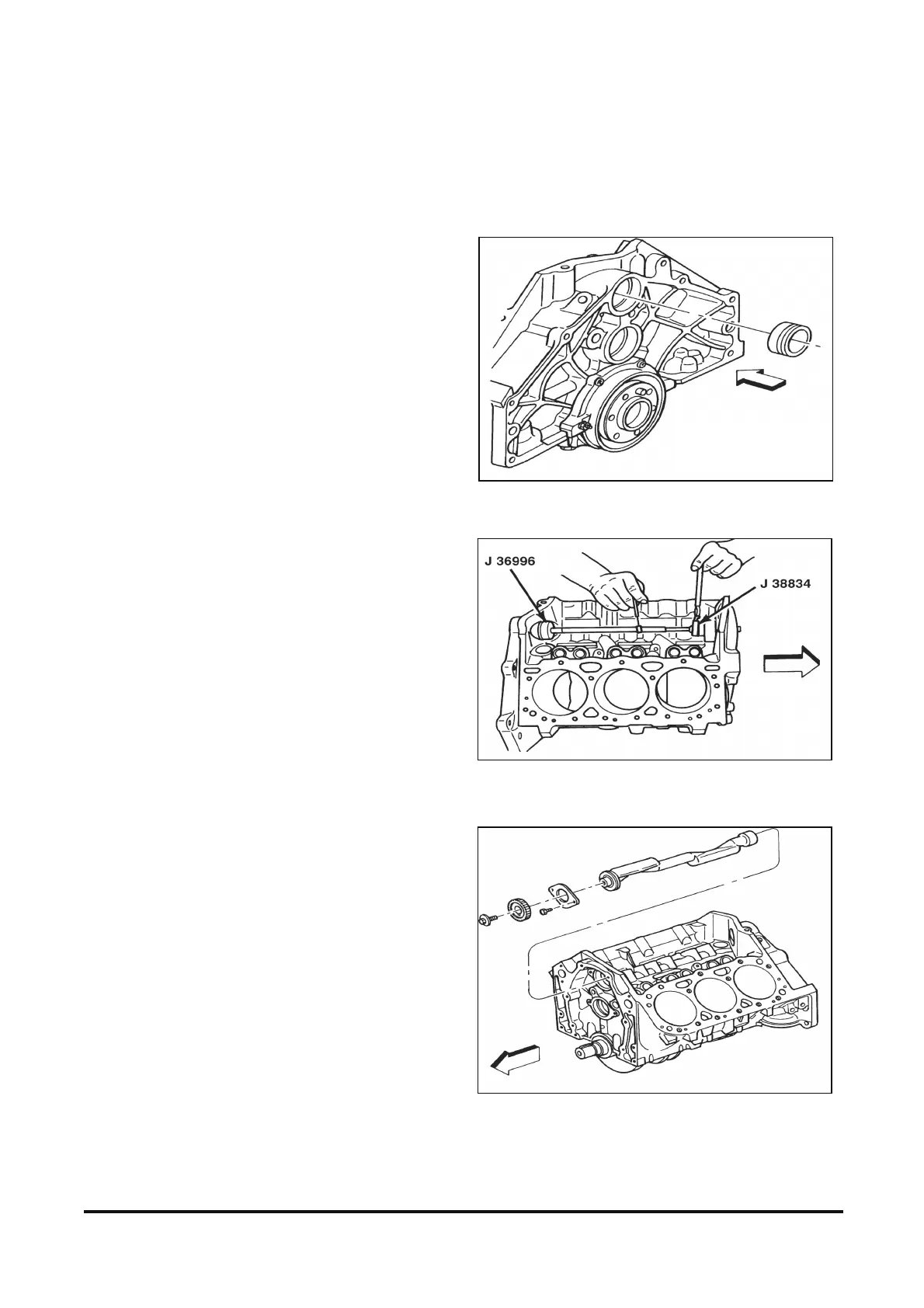

Figure 12-72 Rear Balance Shaft Sleeve Bearing

Figure 12-73 Installing Balance Shaft Rear Bearing

Figure 12-74 Balance Shaft and Components

Loading...

Loading...