G643(E) Service Manual Chapter 5. Engine Management System (EMS) 178

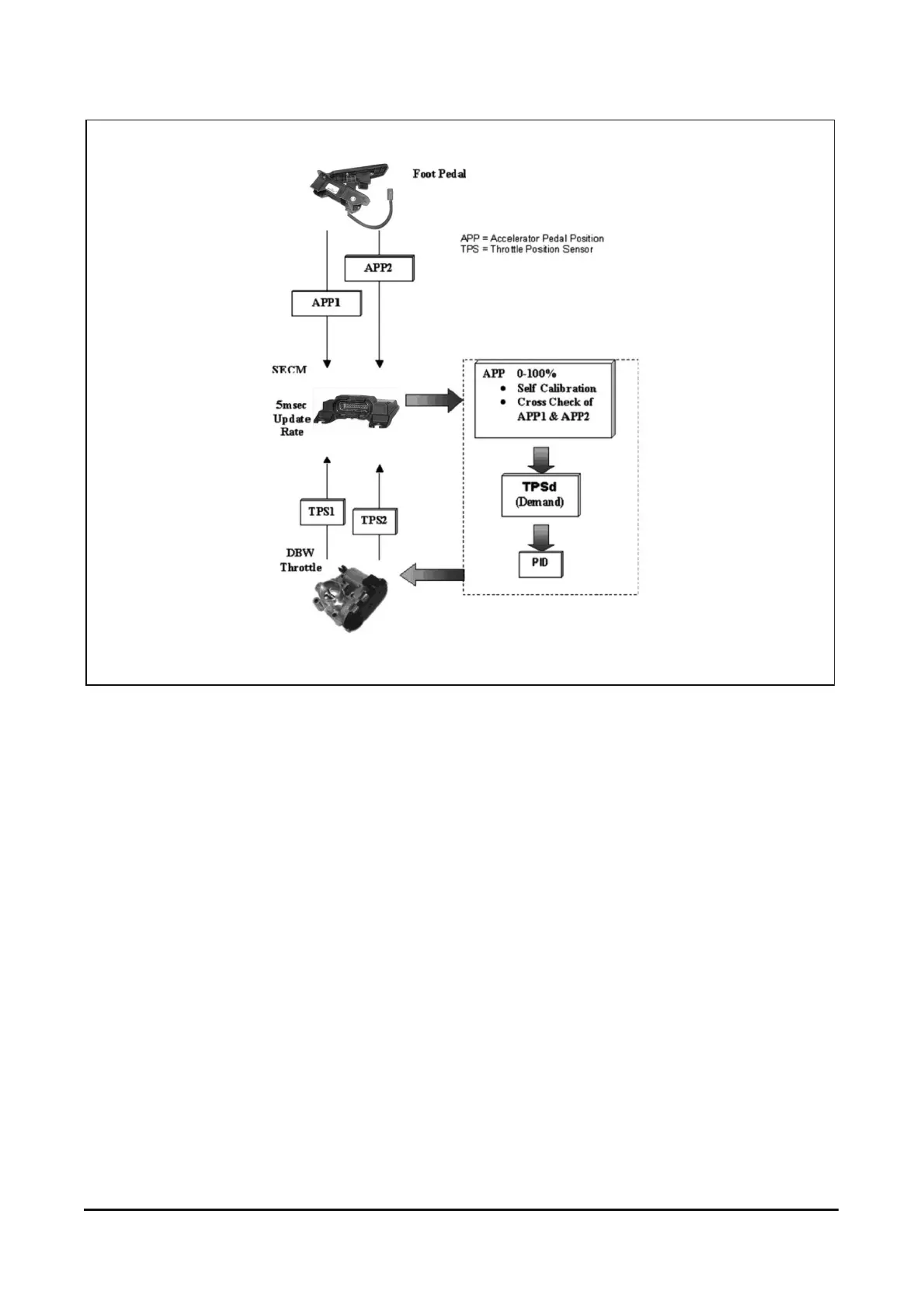

Figure 21. Drive-By-Wire Signal Flow Process

(Figure 21) describes the signal flow process of the

MI-07 DBW section. The foot pedal assembly uses

two potentiometers to detect pedal position. These

two signals, accelerator pedal position 1 (APP1) and

accelerator pedal position 2 (APP2) are sent directly

to the SECM. The SECM uses a series of algorithms

to self calibrate and cross check the signals from the

pedal assembly. A demand position for the throttle

will then be derived and sent to the throttle as a

throttle position sensor demand (TPSd). This signal

will be processed through a PID (Proportional,

Integral, Derivative) controller in the SECM to

achieve the appropriate motor-current response

then passed to the throttle. The throttle moves to the

commanded position and provides a feedback signal

from the throttle position sensor (TPS) to the SECM.

MI-07 Ignition Management

In the normal course of events, with the engine

operating at the correct temperature in defined

conditions, the SECM will use load and engine

speed to derive the correct ignition timing. In

addition to load and speed there are other

circumstances under which the SECM may need to

vary the ignition timing, including low engine coolant

temperature, air temperature, start-up, idle speed

control.

Loading...

Loading...