G643 (E) Service Manual Chapter 3. Engine Mechanical System 80

Measure

• Ring clearance. Use a feeler gage and compare

with “Specifications”.

Figure 12-39 Measuring Ring-to-Land Clearance

Intake and Exhaust Manifolds

Figure 12-40

Clean

• Mating surfaces on intake manifold and cylinder

head.

• Excessive carbon buildup in the exhaust

passages of the intake manifold.

• Scale and deposits from the coolant passages of

the intake manifold.

• EGR passage of excessive carbon deposits.

Inspect

• Manifolds for cracks, broken flanges, and gasket

surface damage.

• Alignment of manifold flanges. Use a straightedge

and feeler gage. If the flanges do not align, the

manifold is warped and should be replaced.

Figure 12-40 Checking Manifold Flange Alignment

Camshaft

Figures 12-41 and 12-42

Tool Required:

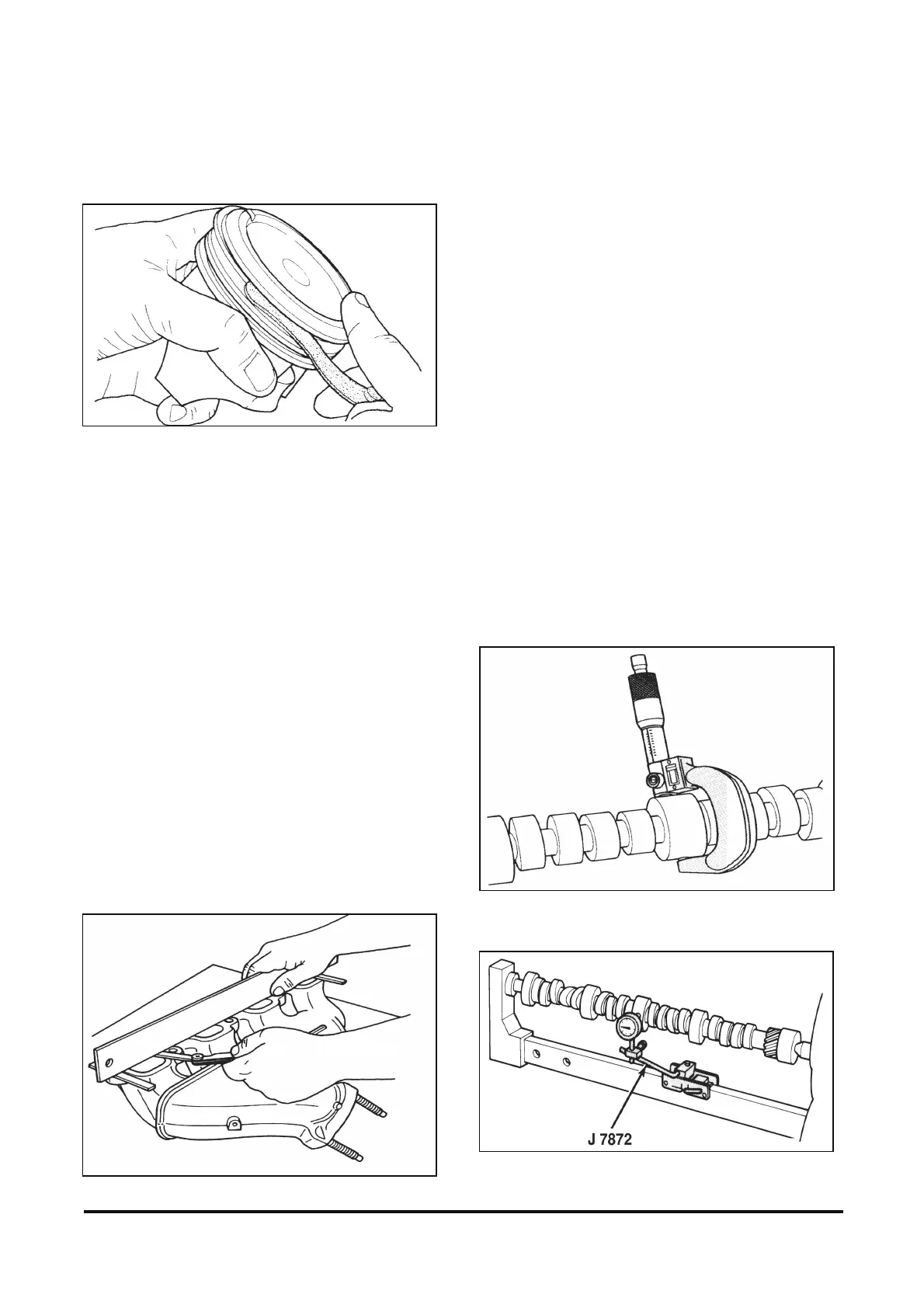

J 7872 Dial Indicator or Equivalent

IMPORTANT: Do not attempt to repair the

camshaft, replace it if damaged. Whenever the

camshaft is replaced, a new set of lifters must

also be installed.

Inspect

• Bearing surfaces and lobes for wear.

• Sprockets.

• Keyway and threads for galling, gouges, or

overheating.

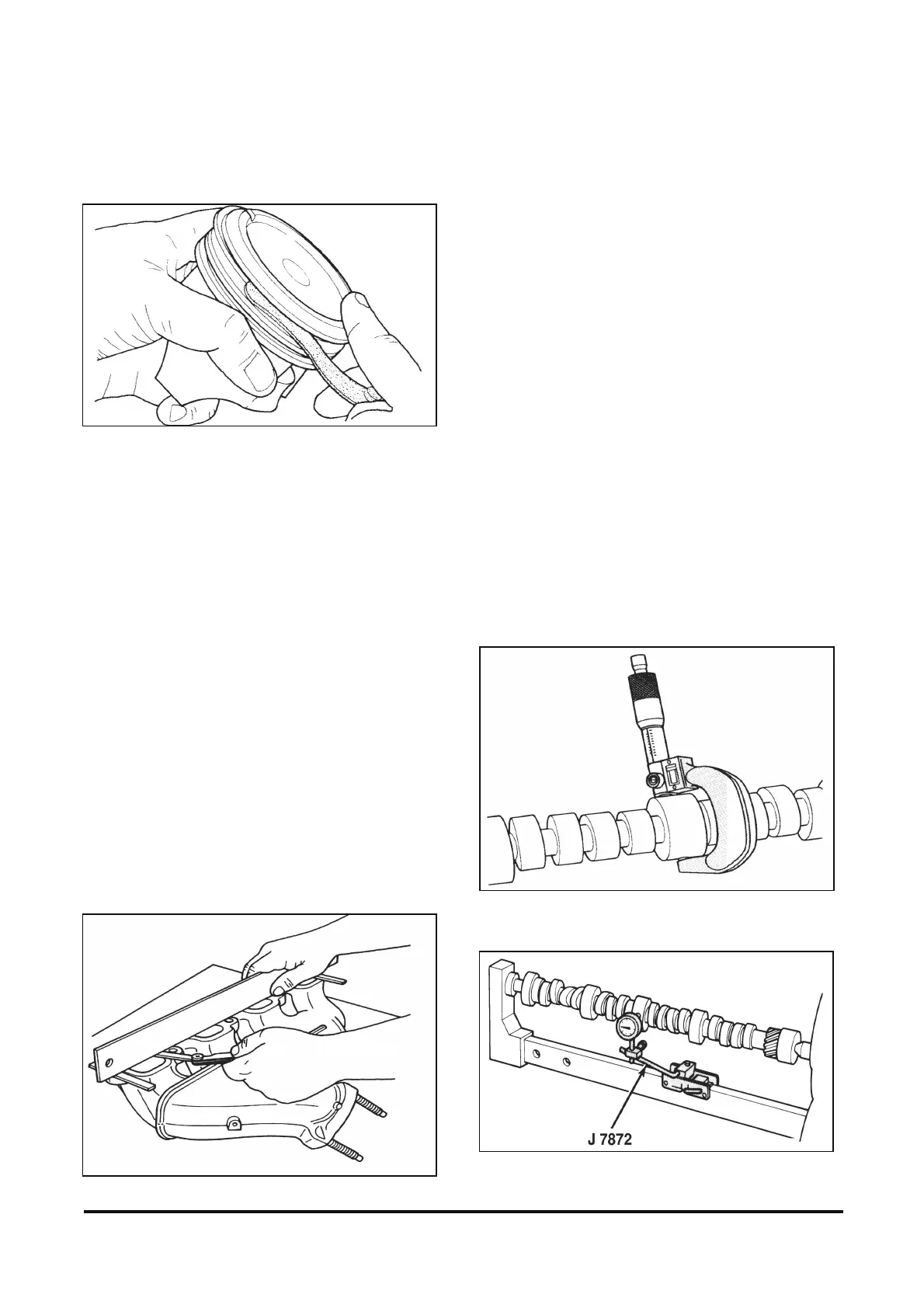

• Camshaft journal diameters (figure 12-41). Refer

to “Engine Specifications” for proper diameters.

• Camshaft runout (figure 12-42). Mount the

camshaft in V-blocks or between centers. Using J

7872, check the intermediate camshaft journal.

Compare camshaft runout with “Specifications”. If

the camshaft is excessively bent, replace the

camshaft and camshaft bearings.

Figure 12-41 Measuring Camshaft Journals

Figure 12-42 Measuring Camshaft Runout

Loading...

Loading...