G643(E) Service Manual Chapter 5. Engine Management System (EMS) 148

G643E EMS (Engine Management System) Overview

General Description

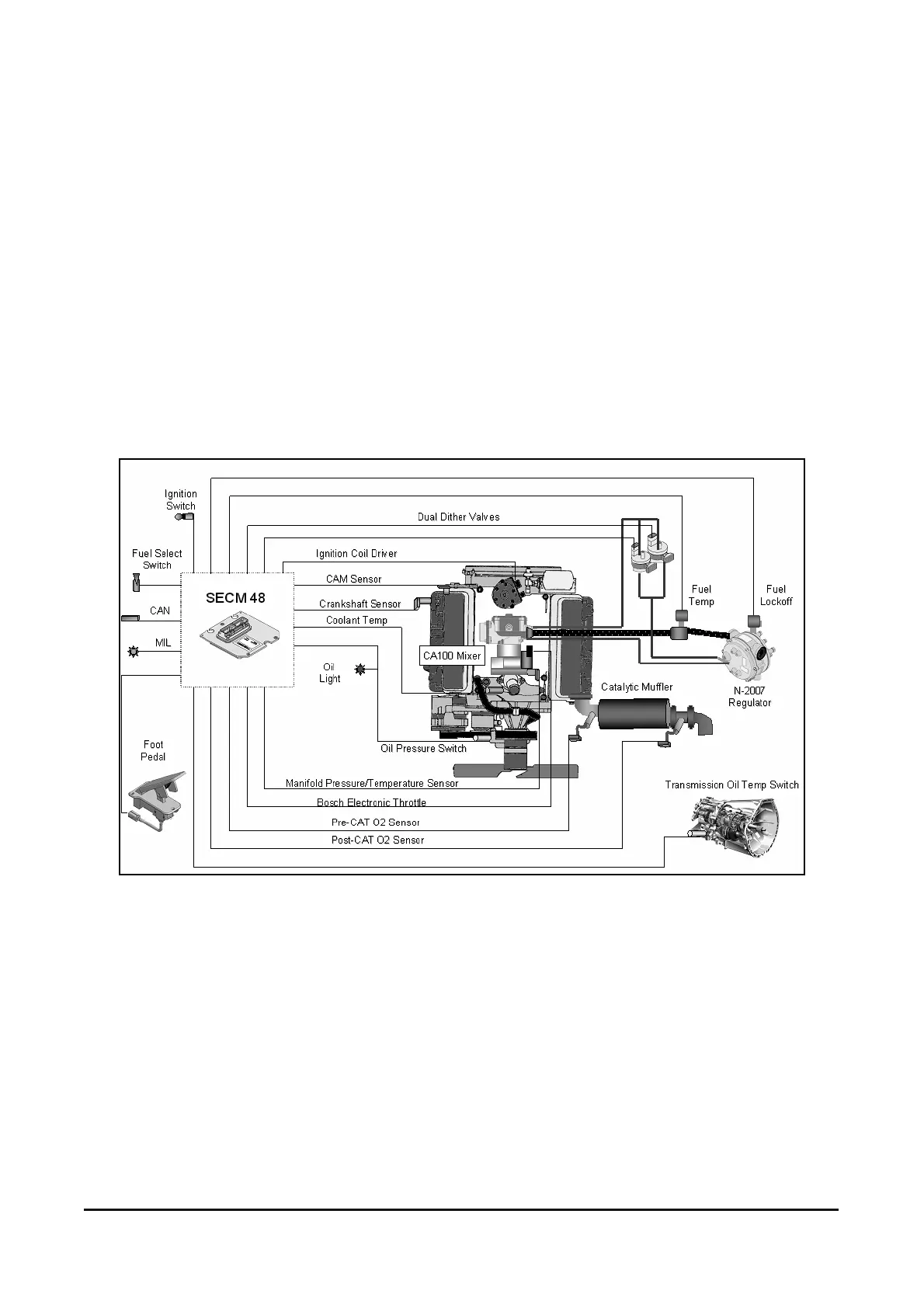

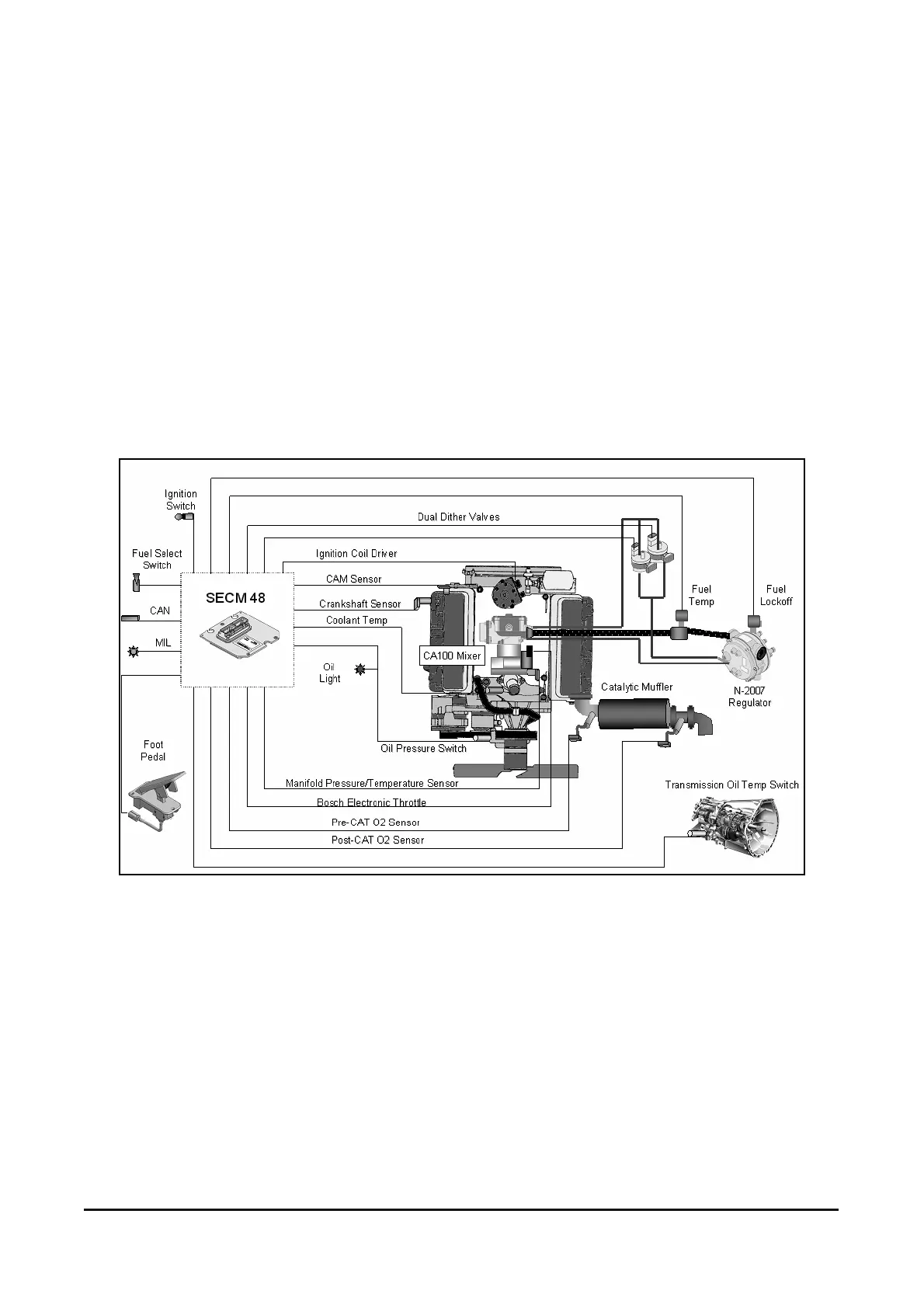

MI-07 control system provides a complete, fully

integrated engine management system that meets

or exceeds 2007 emission standards for Large

Spark Ignited (LSI) engines established by the

California Air Resources Board (CARB) and the

Environmental Protection Agency (EPA).

The control system is applicable to naturally

aspirated engines running on LPG and/or gasoline.

It provides accurate, reliable, and durable control of

fuel, spark, and air over the service life of the engine

in the extreme operating environment found in

heavy-duty, under hood, on-engine electronic

controls.

MI-07 is a closed loop system utilizing a catalytic

muffler to reduce the emission level in the exhaust

gas. In order to obtain maximum effect from the

catalyst, an accurate control of the air fuel ratio is

required. A small engine control module (SECM)

uses two heated exhaust gas oxygen sensors

(HEGO) in the exhaust system to monitor exhaust

gas content. One HEGO is installed in front of the

catalytic muffler and one is installed after the

catalytic muffler.

[Figure 1] MI-07 LP Fuel System for G643E Engine

The SECM makes any necessary corrections to the

air fuel ratio by controlling the inlet fuel pressure to

the air/fuel mixer by modulating the dual fuel trim

valves (FTV) connected to the regulator. Reducing

the fuel pressure leans the air/fuel mixture and

increasing the fuel pressure enriches the air/fuel

mixture. To calculate any necessary corrections to

the air fuel ratio, the SECM uses a number of

different sensors to gain information about the

engine’s performance. Engine speed is monitored

by the SECM through a Variable reluctance (VR)

sensor. Intake manifold air temperature and

absolute pressure are monitored with a TMAP

sensor. MI-07 is a drive-by-wire (DBW) system

connecting the accelerator pedal to the electronic

throttle through the electrical harness; mechanical

cables are not used. A throttle position sensor (TPS)

monitors throttle position in relation to the

accelerator pedal position sensor (APP) command.

Even engine coolant temperature and adequate oil

pressure are monitored by the SECM. The SECM

controller has full adaptive learning capabilities,

allowing it to adapt control function as operating

conditions change. Factors such as ambient

temperature, fuel variations, ignition component

wear, clogged air filter, and other operating variables

are compensated.

Loading...

Loading...