G643 (E) Service Manual Chapter 3. Engine Mechanical System 86

Valve Lifters

This engine uses hydraulic valve lifters. Valve lifters

are serviced only as an assembly. No internal parts

are available. Service is limited to disassembly and

cleaning. Discard valve lifters that are excessively

worn or damaged.

IMPORTANT: Whenever the camshaft needs to

be replaced, a new set of hydraulic lifters must

also be installed.

Cylinder Head

Disassembly

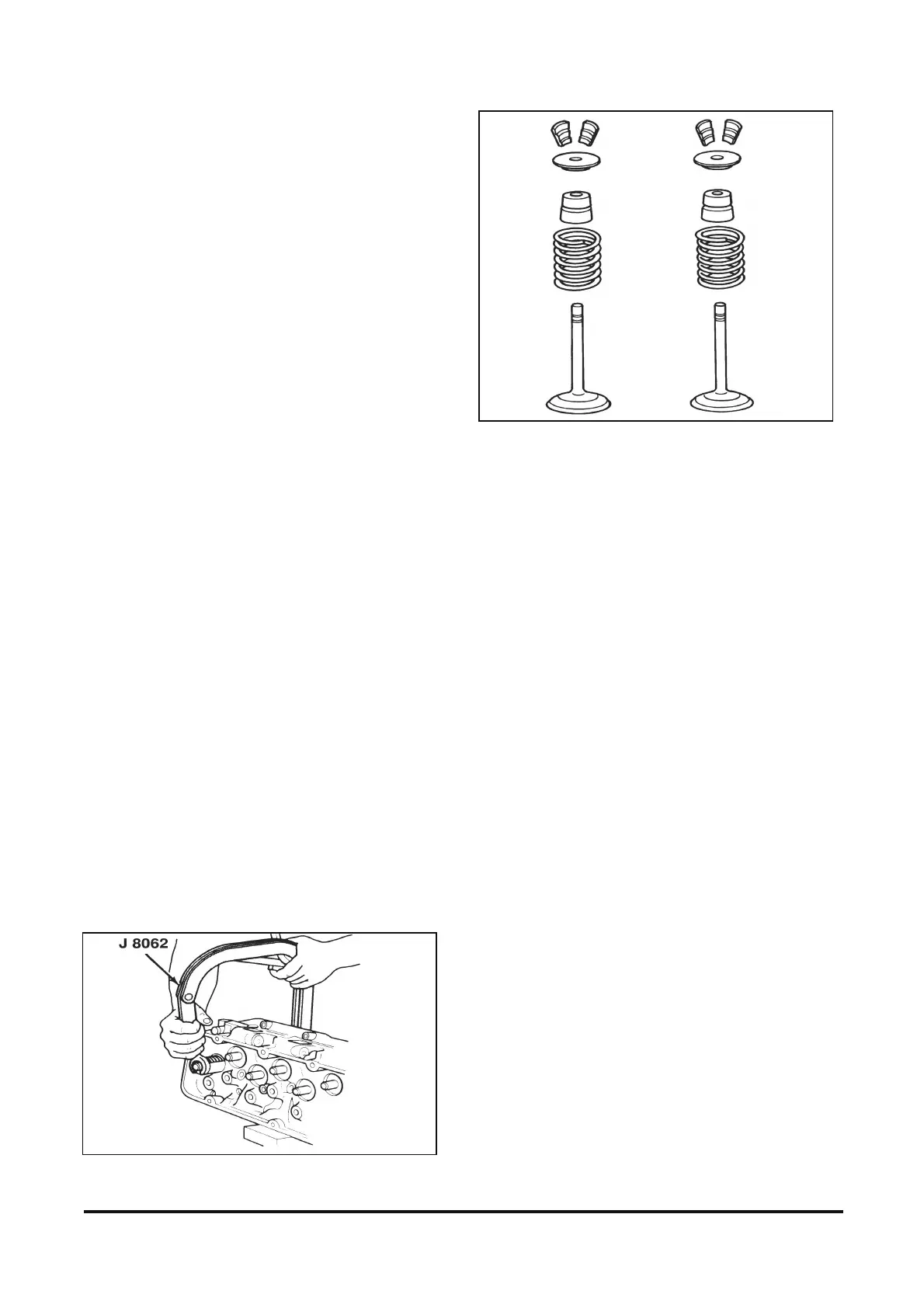

Figures 12-48 and 12-49

Tool Required:

J 8062 Valve Spring Compressor

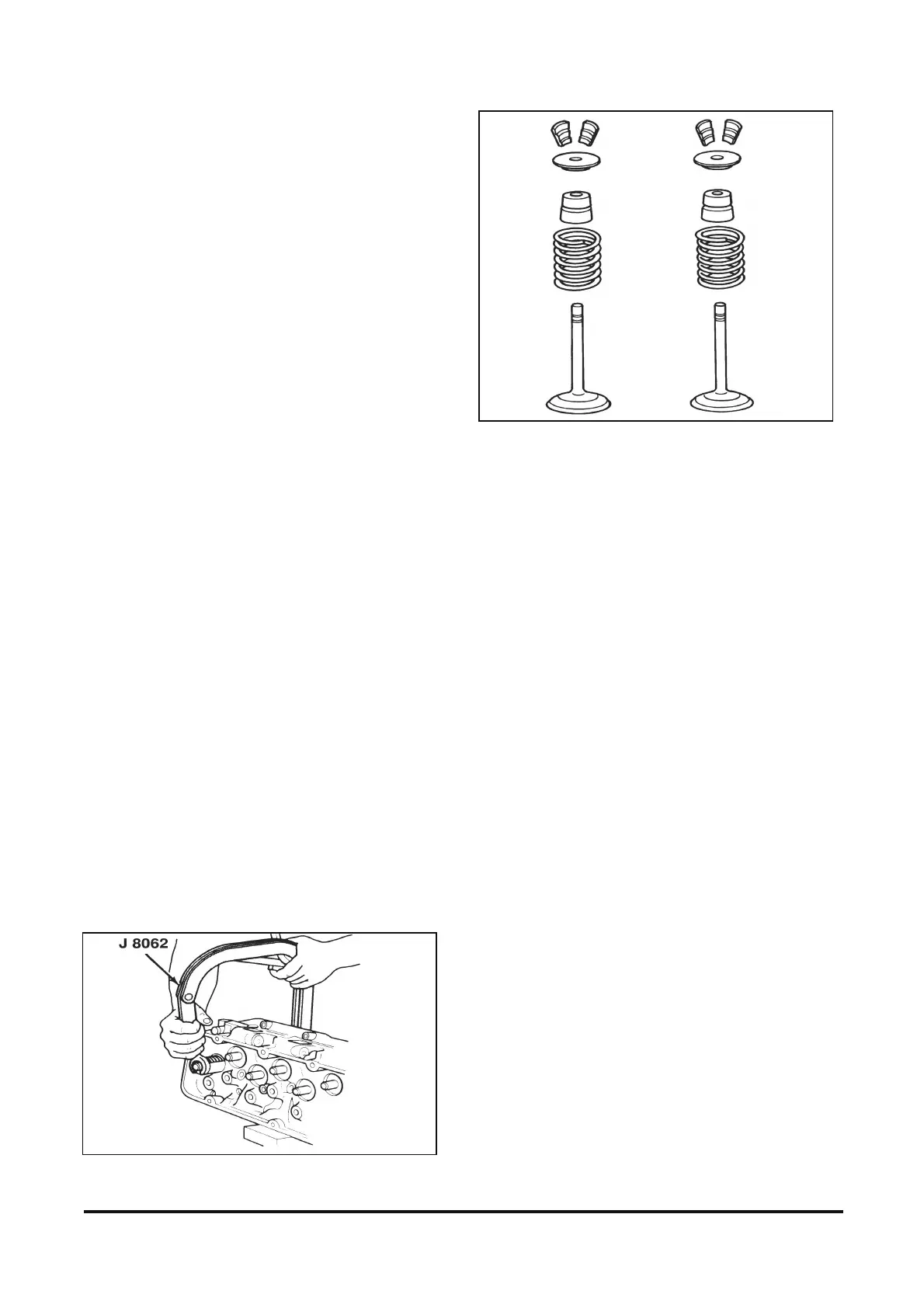

Remove or Disconnect

1. Compress the springs with J 8062

(figure 12-48).

2. Keys.

3. Valve spring cap.

4. Spring.

5. Seal.

6. Valves.

IMPORTANT: Place the valves in an organizer

rack so they can be replaced in their original

position at reassembly.

Figure 12-48 Compressing Valve Springs

Figure 12-49 Valves and Components

Cleaning, Inspection, and Measurement

Figures 12-50 through 12-54

Tool Required:

J 8089 Wire brush

Clean

• Carbon from the combustion chambers using J

8089.

• Valve stems and heads on a wire wheel.

• Carbon and old gasket from the cylinder head

gasket surface.

• Valve guides using a valve guide cleaner.

Inspect

• Cylinder head for cracks in the exhaust ports,

combustion chambers, or external cracks to the

coolant chamber. Gasket surfaces should be free

of damage.

• Valves for burning, pitting, or warpage. Refer to

“Valve Grinding” in this Section. Check the valve

stems for scoring or excessive wear. Stems must

not be bent.

• Valve rocker arm studs for wear, damage, or

improper fit.

• Valve seats for pitting or other damage. Grind or

reface as needed.

• Rotators (if used). The rotators should move

smoothly without binding.

• Cylinder head for surface flatness (figure 12-51).

Loading...

Loading...