G643 (E) Service Manual Chapter 3. Engine Mechanical System 99

Tighten

• Balance shaft driven gear bolt to 20 Nm

(15 lb. ft.) plus an additional turn of 35° using

J 36660.

IMPORTANT: Rotate balance shaft by hand to

make sure there is clearance between the

balance shaft and retainer. If balance shaft does

not rotate freely, check to be sure retaining ring

on front bearing is seated on case. Turn the

camshaft so, with the balance shaft drive gear

temporarily installed, the timing mark on the

drive gear is straight up. With the balance shaft

drive gear removed, turn the balance shaft so

the timing mark on the driven gear points

straight down.

5. Balance shaft drive gear onto camshaft.

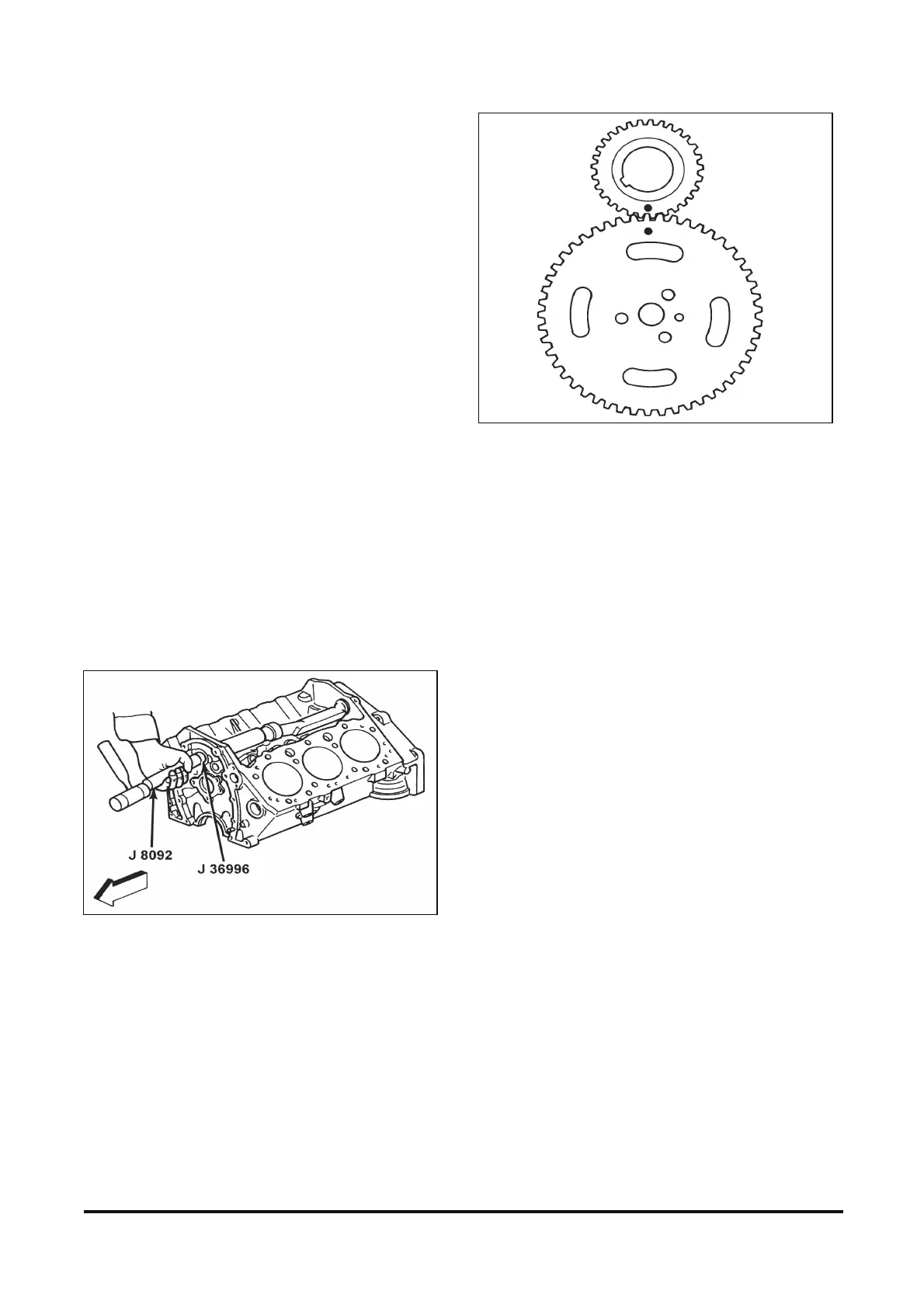

IMPORTANT: Make sure the timing marks on the

balance shaft drive gear and driven gear line up

(figure 12-76).

6. Balance shaft drive gear bolt.

Tighten

• Bolt to 16 Nm (12 lb. ft.).

Figure 12-75 Installing Balance Shaft

Figure 12-76 Balance Shaft Drive Gear-to- Driven Gear Timing

Marks

Camshaft Installation

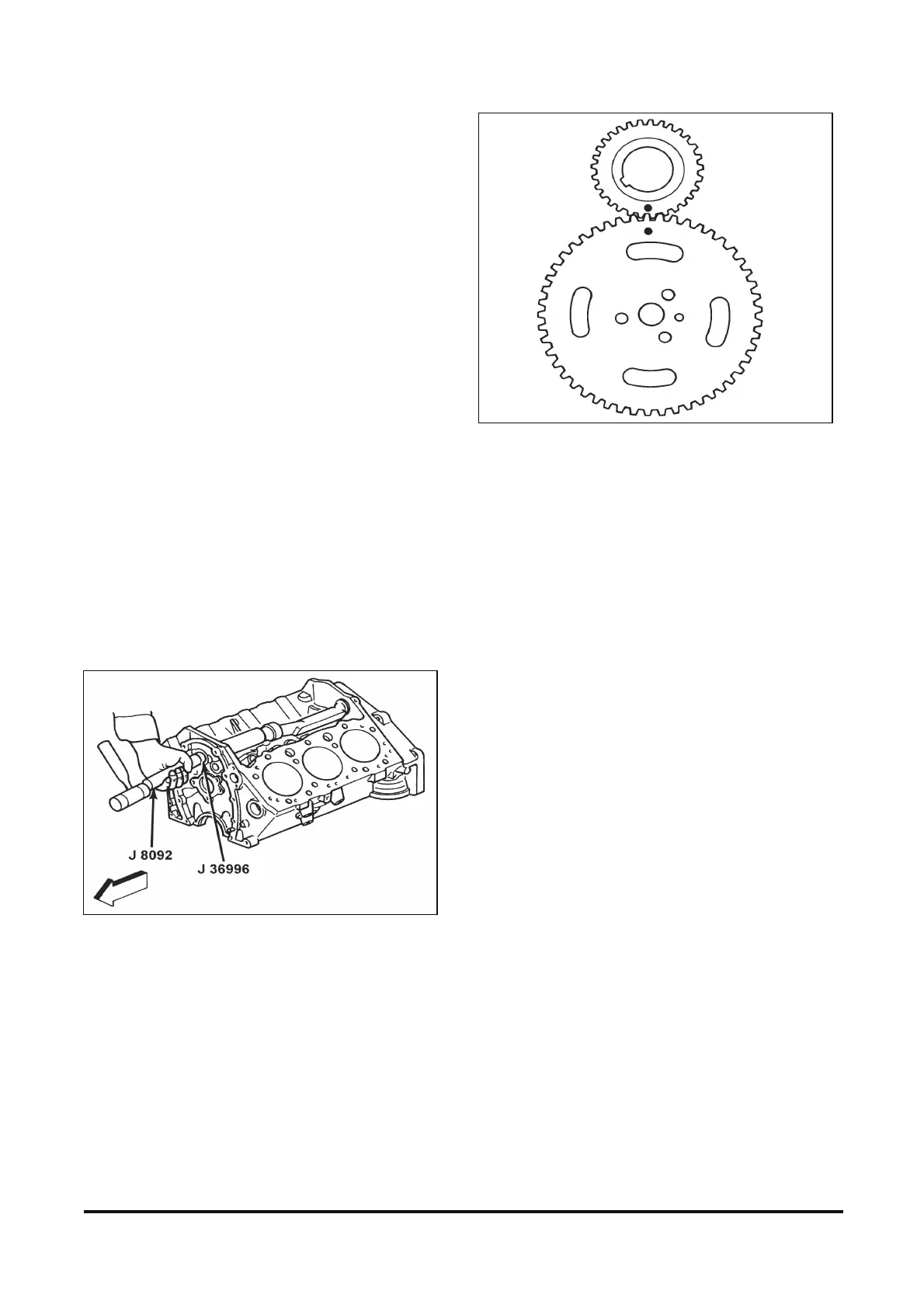

Figure 12-77

Install or Connect

IMPORTANT: Coat camshaft lobes and journals

with Engine Oil Supplement (GM P/N 1052367) or

equivalent. Apply Engine Oil Supplement (GM

P/N 1052367) or equivalent, to all the teeth on the

distributor drive gear.

1. Install three 5/16 x 18 bolts 100 - 125 mm (4 - 5

in.) long into the camshaft threaded holes. Use

these bolts to handle the camshaft.

2. Camshaft to the engine (figure 12-77). Handle

the camshaft carefully to prevent damage to the

camshaft bearings.

NOTICE: Refer to “Notice” on page 1.

3. Camshaft retainer and retainer bolts. Coat

camshaft retainer plate with Engine Oil

Supplement (GM P/N 1052367) or equivalent.

Tighten

• Bolts to 14 Nm (124 lb. in.).

Loading...

Loading...