G643 (E) Service Manual Chapter 3. Engine Mechanical System 101

Torsional Damper Installation

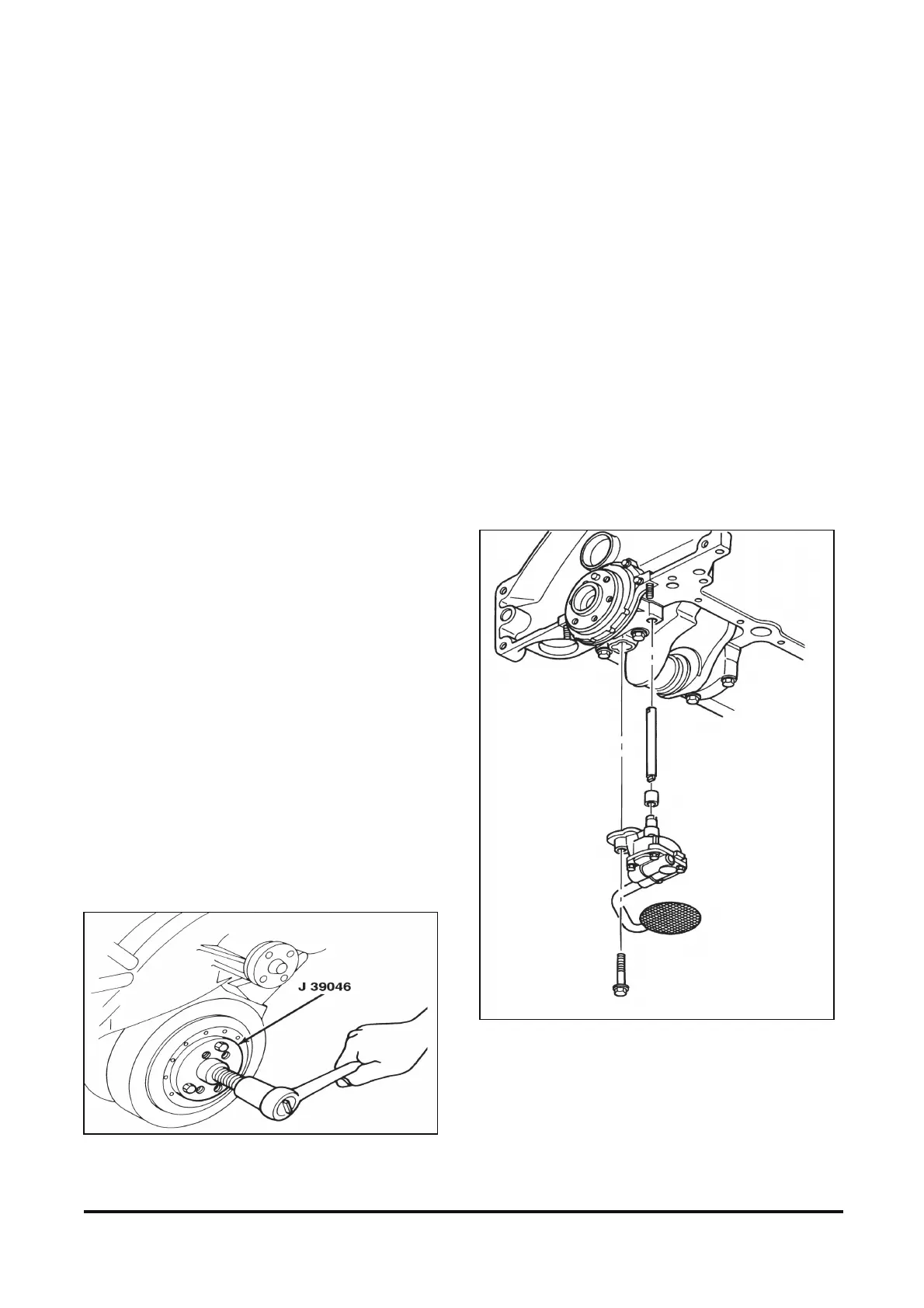

Figure 12-79

Tool Required:

J 39046 Torsional Damper Puller and Installer

Install or Connect

1. Apply RTV sealant GM P/N 12345739 to

crankshaft keyway (if removed).

2. Crankshaft key (if removed).

NOTICE: The inertial weight section of the torsional

damper is assembled to the hub with rubber type

material. The correct installation procedures (with

the proper tool) must be followed or movement of

the inertial weight section of the hub will destroy the

tuning of the torsional damper.

3. Stud (part of J 39046) to the crankshaft. Thread

the stud fully into the tapped hole in the

crankshaft.

4. Torsional damper over the end of the stud. Align

the keyway in the torsional damper shaft with the

crankshaft key.

5. Bearing, washer, and nut.

A. Turn the nut to pull the torsional damper into

place (figure 12-79).

B. Remove the tool.

6. Torsional damper bolt and washer.

NOTICE: Refer to “Notice” on page 1.

Tighten

• Bolt to 95 Nm (70 lb. ft.).

Figure 12-79 Installing Torsional Damper

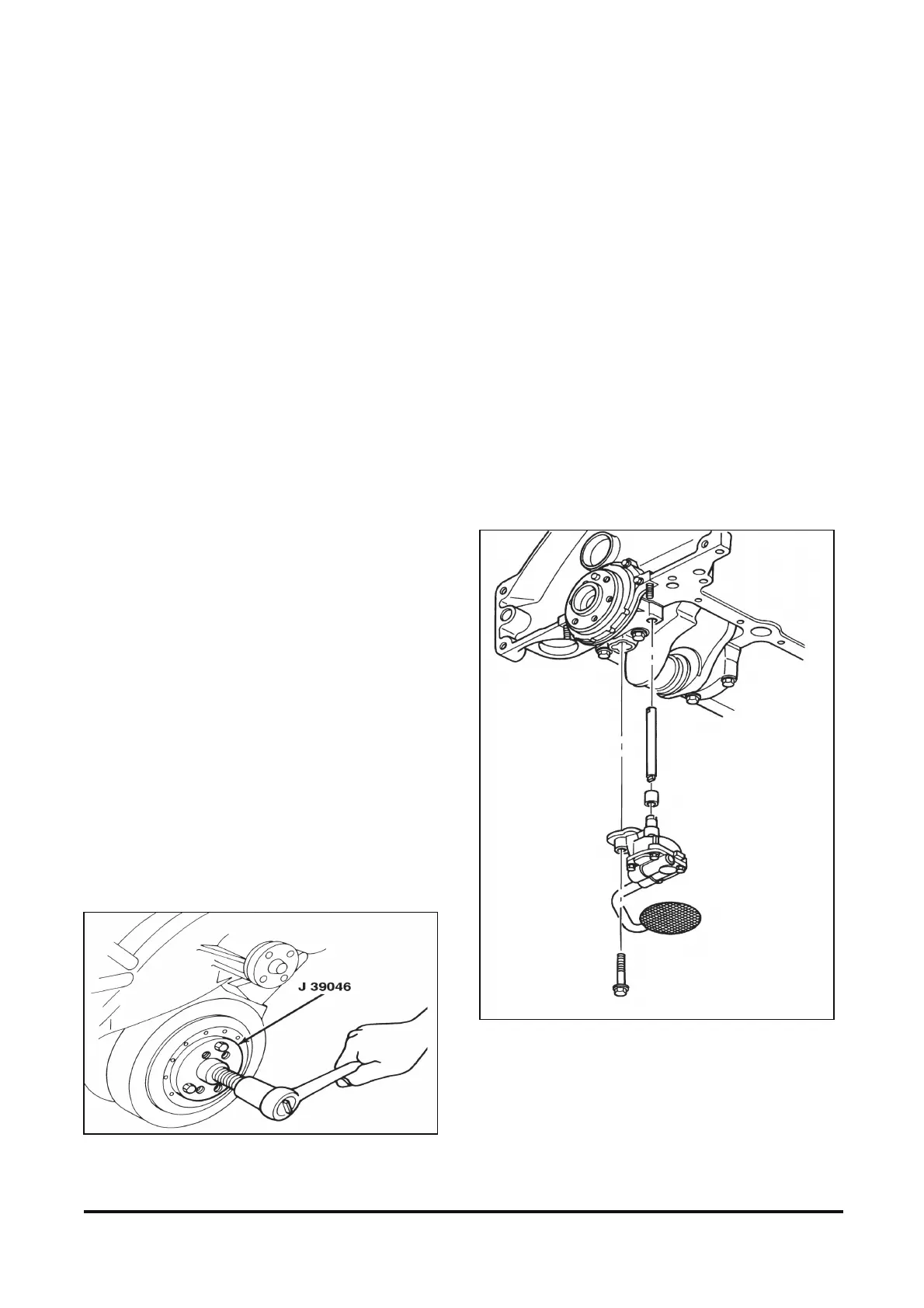

Oil Pump Installation

Figure 12-80

Install or Connect

1. Oil pump to the engine.

• Align the slot in the oil pump shaft with the tang

on the distributor shaft.

• The oil pump should slide easily into place.

• No gasket is used.

2. Oil pump to main bearing cap bolt.

NOTICE: Refer to “Notice” on page 1.

Tighten

• Oil pump to main bearing cap bolt to 90 Nm

(66 lb. ft.).

Figure 12-80 Oil Pump Installation

Loading...

Loading...