G643(E) Service Manual Chapter 5. Engine Management System (EMS) 150

MI-07 System Components

The MI-07 control system provides electronic control

to the following subsystems on mobile industrial

engines:

• Fuel delivery system

• Spark-ignition control system

• Air throttle

• Sensors/Switches/Speed inputs

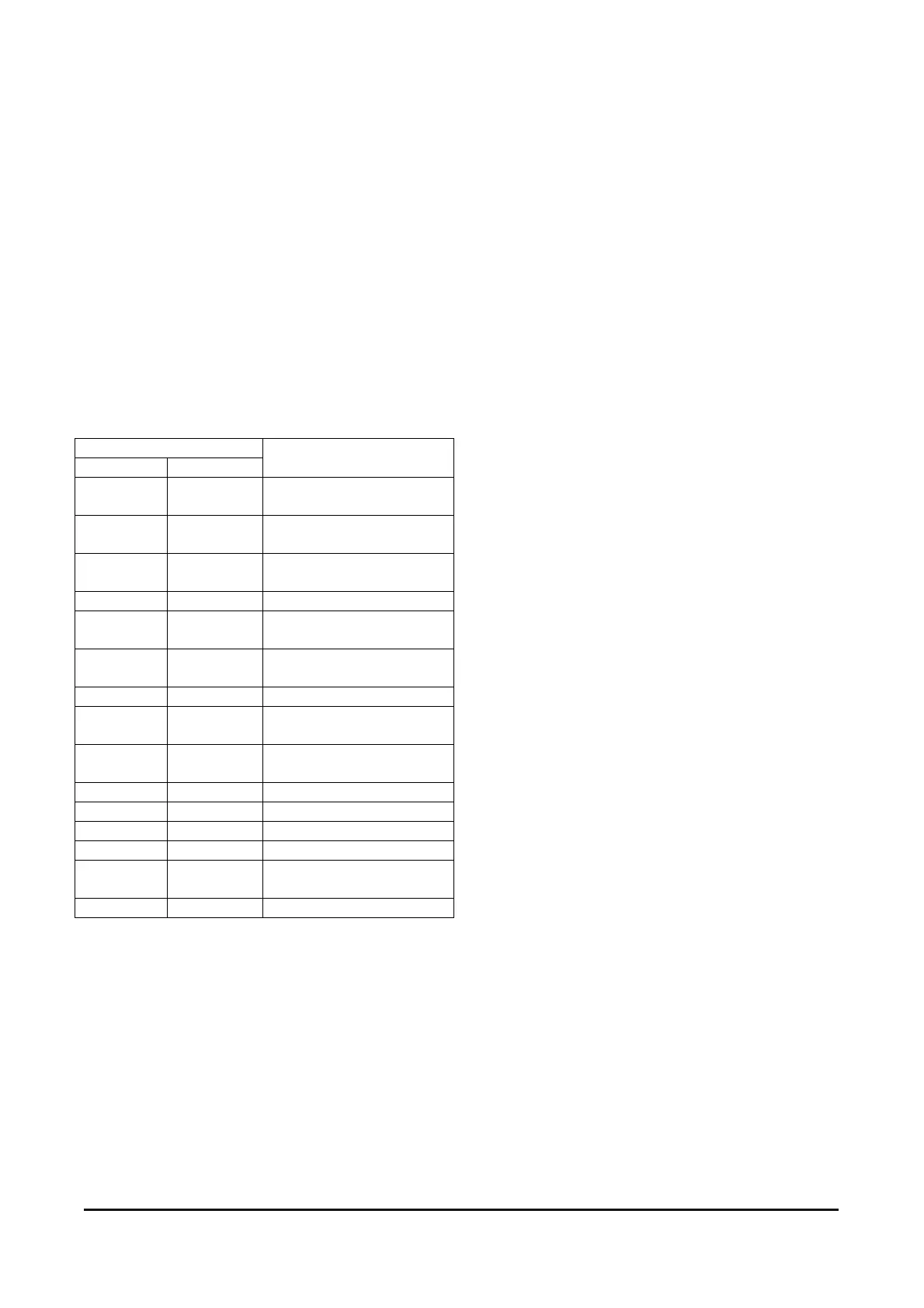

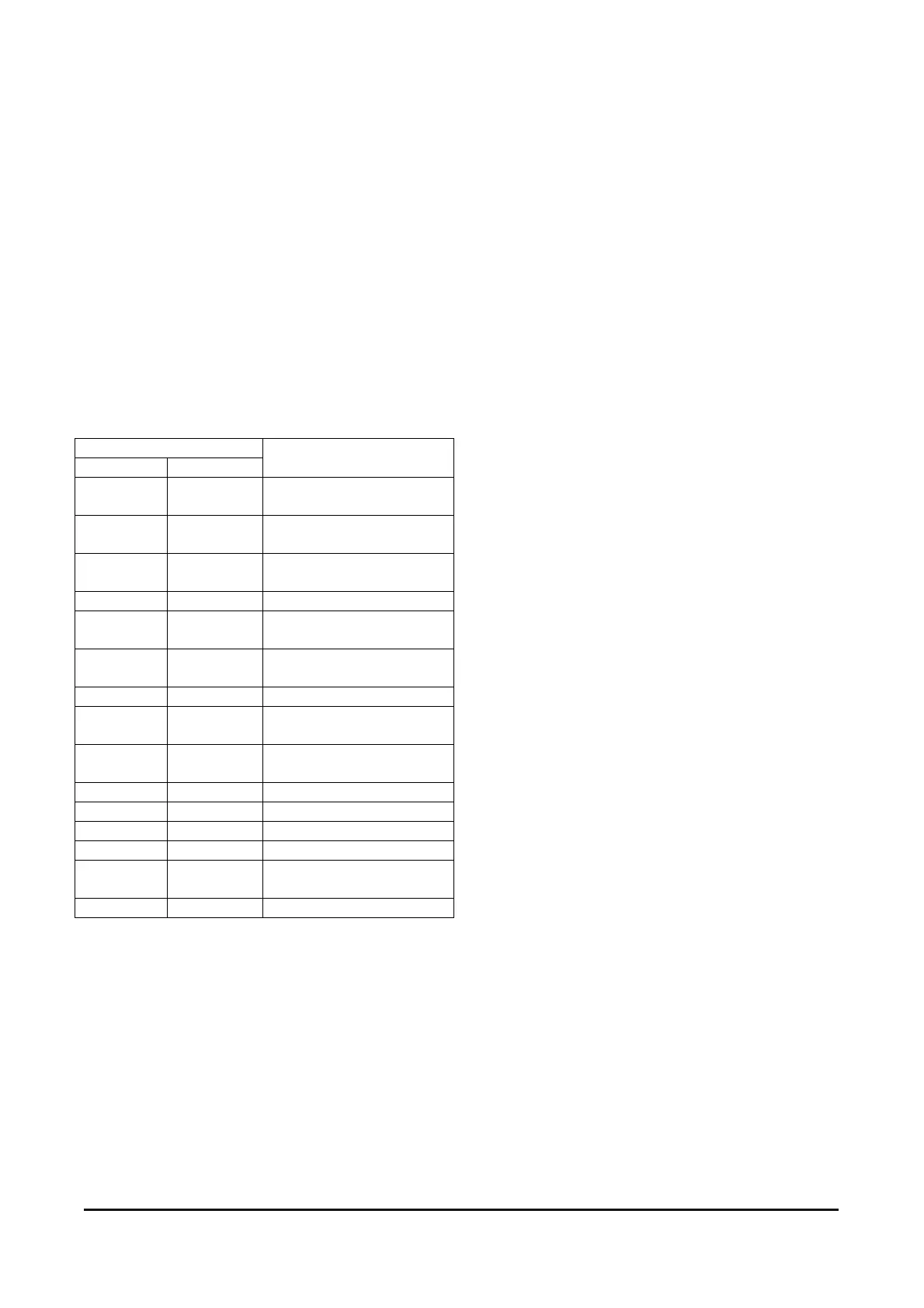

The chart below lists the MI-07 components required

for a G643 (E) engine operating on LP fuel.

Q’ty

G643E G643

DESCRIPTION

1 1 Engine Control Module

(SECM)

None None Camshaft Position

Sensor

1 1 Crankshaft Position

Sensor

1 1 TMAP Sensor

1 None Fuel Temperature

Sensor

1 None Transmission Oil

Temperature Switch

2 None Oxygen Sensors

1 1 Coolant Temperature

Sensor

1 1 Engine Oil Pressure

Switch

2 None Fuel Trim Valve

1 1 Ignition Coil

1 1 Fuel Lock Off Solenoid

N-2007 N-2001 LP Regulator

CA-100

(Certified)

CA-100 LP Mixer

1 1 Electronic Throttle Body

Key Components

The MI-07 system functions primarily on engine

components that affect engine emissions and

performance. These key components include the

following:

• Engine/Combustion chamber design

• Intake/Exhaust valve configuration, timing and lift

• Intake/Exhaust manifold design

• Catalytic converter and exhaust system

• Throttle body

• Air intake and air filter

• LPG mixer

• LPG pressure regulator

• Fuel trim valves

• Fuel trim orifices

• Small engine control module (SECM), firmware

and calibration †

• Fuel system sensors and actuators

• Ignition system including spark plugs, cables, coils

and drivers

MI-07 System Features

The MI-07 system uses an advanced speed-density

control strategy for fuel, spark, and air throttle

control. Key features include the following.

• Closed-loop fuel control

• Speed-load spark control with tables for dwell,

timing, and fuel type

• Speed-load throttle control with table for maximum

TPS limiting

• Closed-loop fuel control with two oxygen sensors

(one installed pre catalyst and one installed post

catalyst). The pre-catalyst oxygen sensor includes

adaptive learn to compensate for fuel or

component drift. The post-catalyst oxygen sensor

includes adaptive learn to compensate the pre-

catalyst oxygen sensor setting for pre-catalyst

oxygen sensor drift and catalyst aging. The pre-

catalyst oxygen sensor function includes

parameters for transport delay, O2 set point,

excursion rich/lean, jump back rich/lean, and

perturbation.

• LPG fuel temperature compensation

• Min/max governing

• All-speed isochronous governing

Loading...

Loading...