G643(E) Service Manual Chapter 6. LPG FUEL DELIVERY SYSTEM 202

6. If present, set fuel select switch to LPG fuel.

When operated at the factory, it is critical to simulate

the airflow found on a forklift at idle as nearly as

possible in order to achieve the proper air valve lift

in the mixer. It may be necessary to place a load on

the engine to achieve the required airflow without

overspeeding the engine. Means of achieving this

load include:

a) Place an electrical load on the alternator. The

alternator should be able to briefly hold loads

of approximately 1.2 kW.

b) Attach the engine to a dynamometer.

Attach the Mototune Service Tool to the wiring

harness and add parameter MAFPort to the display

screen.

Factory Adjustment Procedure:

NOTE : Be sure engine is fully warm (ECT>167°F

[75°C]) before performing the idle mixture

adjustment.

1. Operating the engine on LPG fuel, start the

engine and permit the engine to warm up until the

coolant temperature (ECT on Mototune display) is

approximately 167°F (75 oC).

2. Set APP input to minimum.

3. Adjust the load until engine speed reaches 750

rpm.

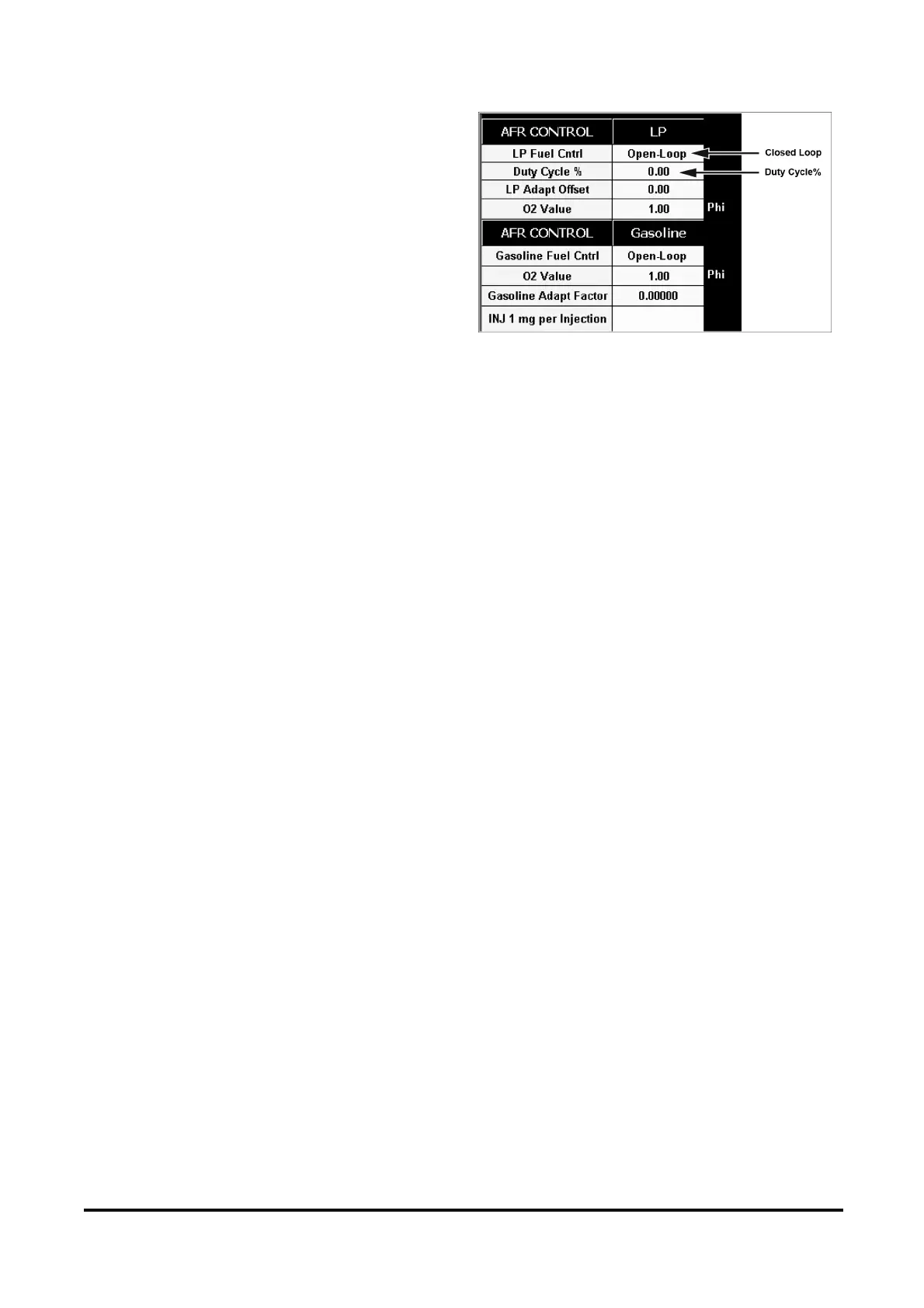

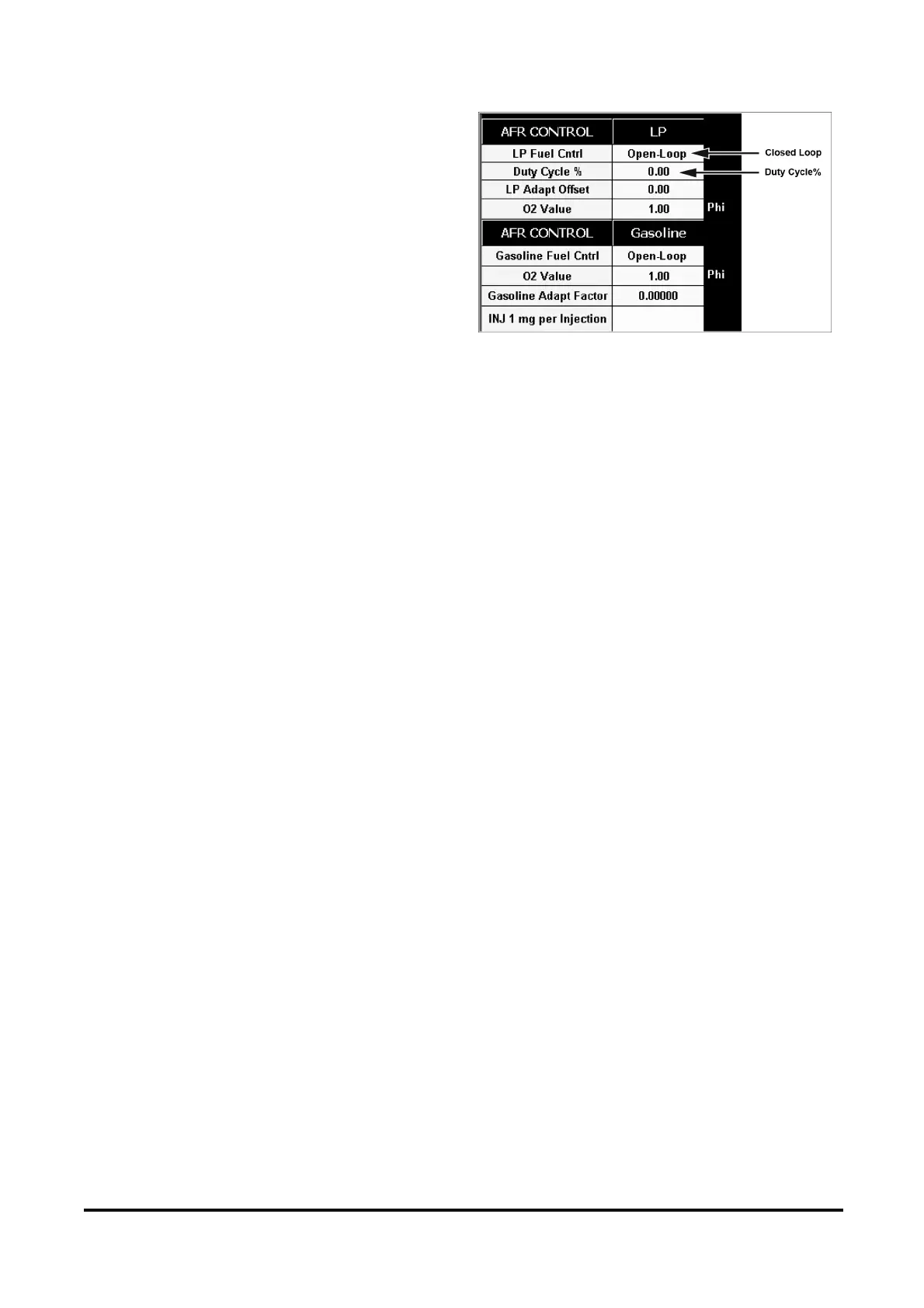

4. Mototune display parameter LP Fuel Control must

display “Closed Loop.”

5. Use the Mototune Service Tool to monitor Duty

Cycle % on the Mototune display.

6. To adjust the idle mixture screw, use a 5mm hex

or Allen-type wrench. Turning the screw in

(clockwise) should increase the duty cycle; turning

the screw out (counter-clockwise) should

decrease the duty cycle.

7. Adjust the idle mixture screw on the mixer until a

reading of 40-45% is reached for the FTV Duty

Cycle in Closed Loop Idle (Figure 35).

Figure 41. FTV Duty Cycle Percentage Displayed on

Service Tool

8. Use the accelerator pedal to increase RPM above

idle momentarily (rev the engine) then release the

pedal to return to idle RPM. The duty cycle setting

should remain within the adjustment range (40-

45%). Place your thumb over the adjustment port

for a more accurate reading by preventing air from

leaking past the mixture adjustment screw, which

may cause the duty cycle to decrease.

9. Use the Mototune Service Tool to lock the FTV

duty cycle. Set display parameter

DitherValveDC_ovr = locked (displayed in screen

tab Manual Override 1 under AFR Trim Vales,

select “locked” under box labeled Lock DC%).

10. Use the Mototune Service Tool to monitor

throttle position (TPS1) and Exhaust gas oxygen

equivalence ratio (“O2 Value” in Figure 1). While

monitoring O2, slowly increase the pedal input

(APP) to achieve a TPS1 value of 15%.

11. Use the Mototune Service Tool to unlock the

FTV duty cycle. Set display parameter

DitherValveDC_ovr = unlocked (displayed in

screen tab Manual Override 1 under AFR Trim

Vales, select “unlocked” under box labeled Lock

DC%).

12. If at any time in step 10, O2 was greater than 1.2

go to step 13. If 02 remained below 1.2,

proceed to Step 15.

13. Adjust the idle mixture screw on the mixer until a

reading of 50-55% is reached for the FTV Duty

Cycle in Closed Loop Idle (Figure 35).

Loading...

Loading...