G643 (E) Service Manual Chapter 3. Engine Mechanical System 74

1. Refer to “Specifications” for tolerances.

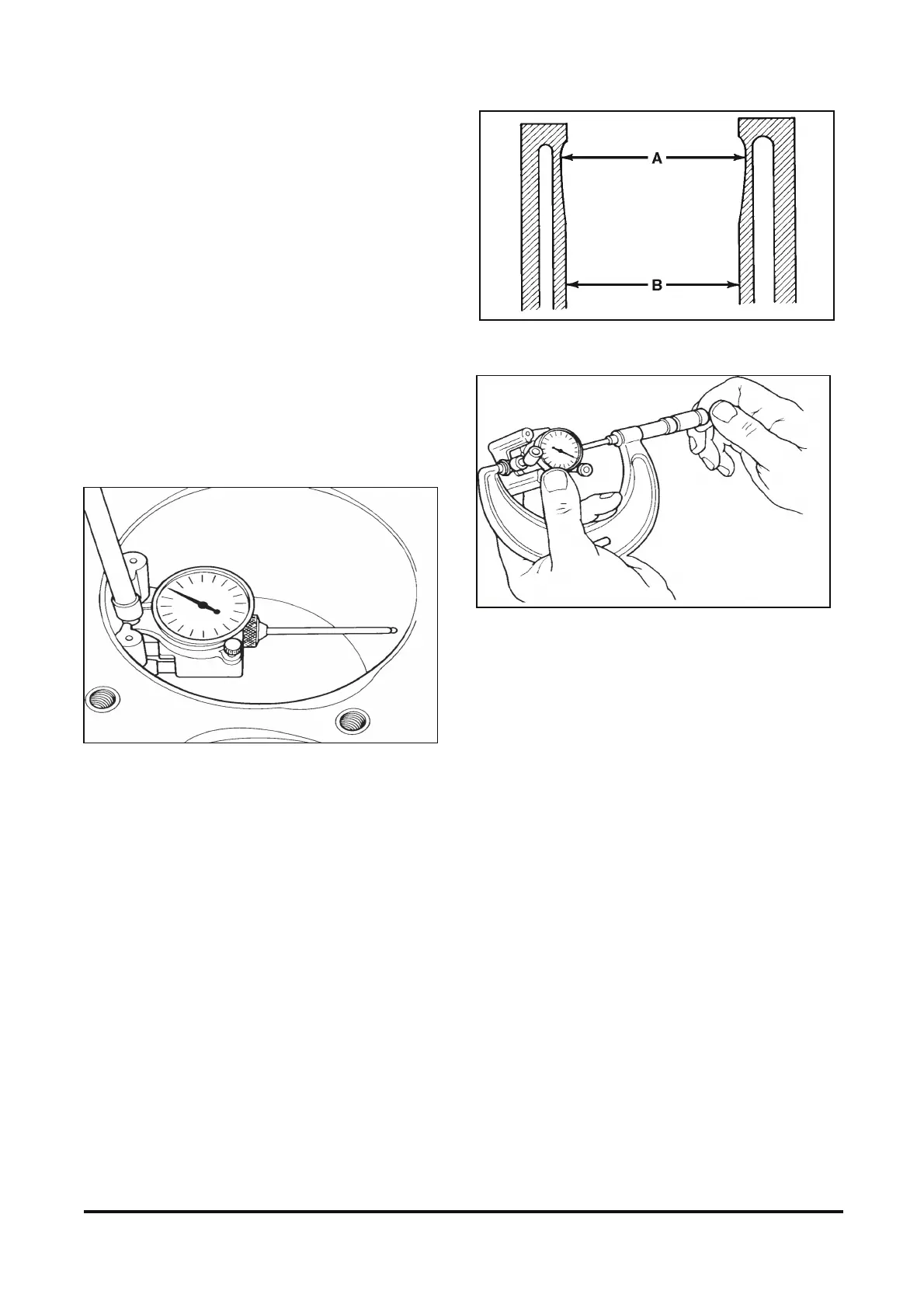

2. Set the gage so the thrust pin must be forced in

about 7 mm (0.250 in.) to enter the gage in the

cylinder bore.

3. Center the gage in the cylinder and turn the dial

to “0”.

4. Carefully work the gage up and down to

determine taper and turn it to different points

around the cylinder wall to determine the out-of-

round condition. Measure the bore both parallel

to and at right angles to the engine centerline.

Measure at the top, middle, and bottom of the

bore and note the readings.

5. Recondition the cylinder bore as necessary, as

outlined later.

Figure 12-26 Checking the Cylinder Bore

Cylinder Bore Reconditioning

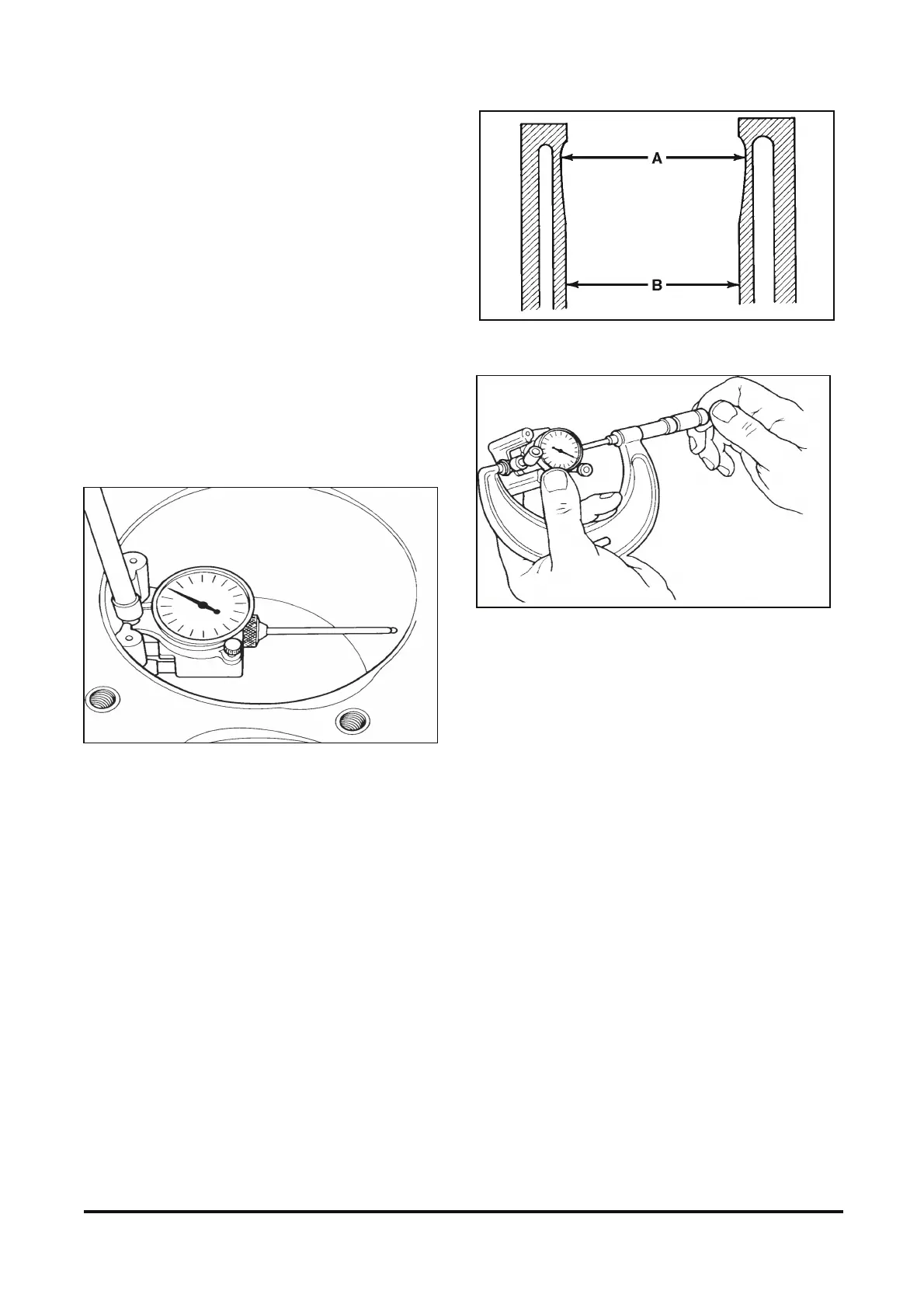

Figures 12-27 and 12-28

1. Measure the cylinder bore for out of round and

taper as outlined previously.

2. Measure for wear at the top of the bore (point

“A”) and at the bottom (point “B”).

• Cylinder bores can be measured by setting the

cylinder gage dial at zero in the cylinder at the

point of desired measurement. Lock the dial

indicator at zero before removing from the

cylinder, and measure across the gage contact

points with an outside micrometer, with the

gage at the same zero setting when removed

from the cylinder (figure 12- 28).

Figure 12-27 Typical Cylinder Wear Pattern

Figure 12-28 Measuring Cylinder Bore Gage

3. If the cylinders are found to exceed the specified

out-of-round or taper, honing or boring will be

necessary. Any cylinders that were found to have

less than 0.13 mm (0.005 in.) wear or taper may

not entirely clean up when fitted to a high limit

piston. If it is desired to entirely clean up the bore

in these cases, it will be necessary to rebore for

an oversize piston. If more than 0.13 mm (0.005

in.) taper or wear, they should be bored and

honed to the smallest oversize that will permit

complete resurfacing of all cylinders.

4. Fine vertical scratches made by ring ends will

not, by themselves, cause excessive oil

consumption; therefore, honing to remove them

is unnecessary.

5. Make sure the honing stones are clean, sharp,

and straight. Move the hone up and down to

produce a 45° to 65° cross-hatch pattern. Clean

the bore thoroughly with soap and water. Dry

and rub in clean engine oil, then remeasure.

6. If honing is not required, the cylinder bores

should be cleaned with a hot water and

detergent wash. Apply clean engine oil to the

bore after cleaning.

Loading...

Loading...