G643 (E) Service Manual Chapter 3. Engine Mechanical System 89

Valve Seat Grinding

Reconditioning the valve seats is very important.

The seating of the valves must be perfect for the

engine to deliver the power and performance it was

designed to produce.

Another important factor is the cooling of the valve

head. Good contact between each valve and its seat

will ensure that heat will be carried away properly.

Several different types of equipment are available

for refacing valves. The manufacturer's instructions

for how to use the equipment should be carefully

followed to attain the proper results.

Regardless of what type of equipment is used, it is

essential that valve guide bores be free from carbon

or dirt to ensure proper centering of the pilot in the

guide. Refer to “Specifications” for valve seat angle

specifications.

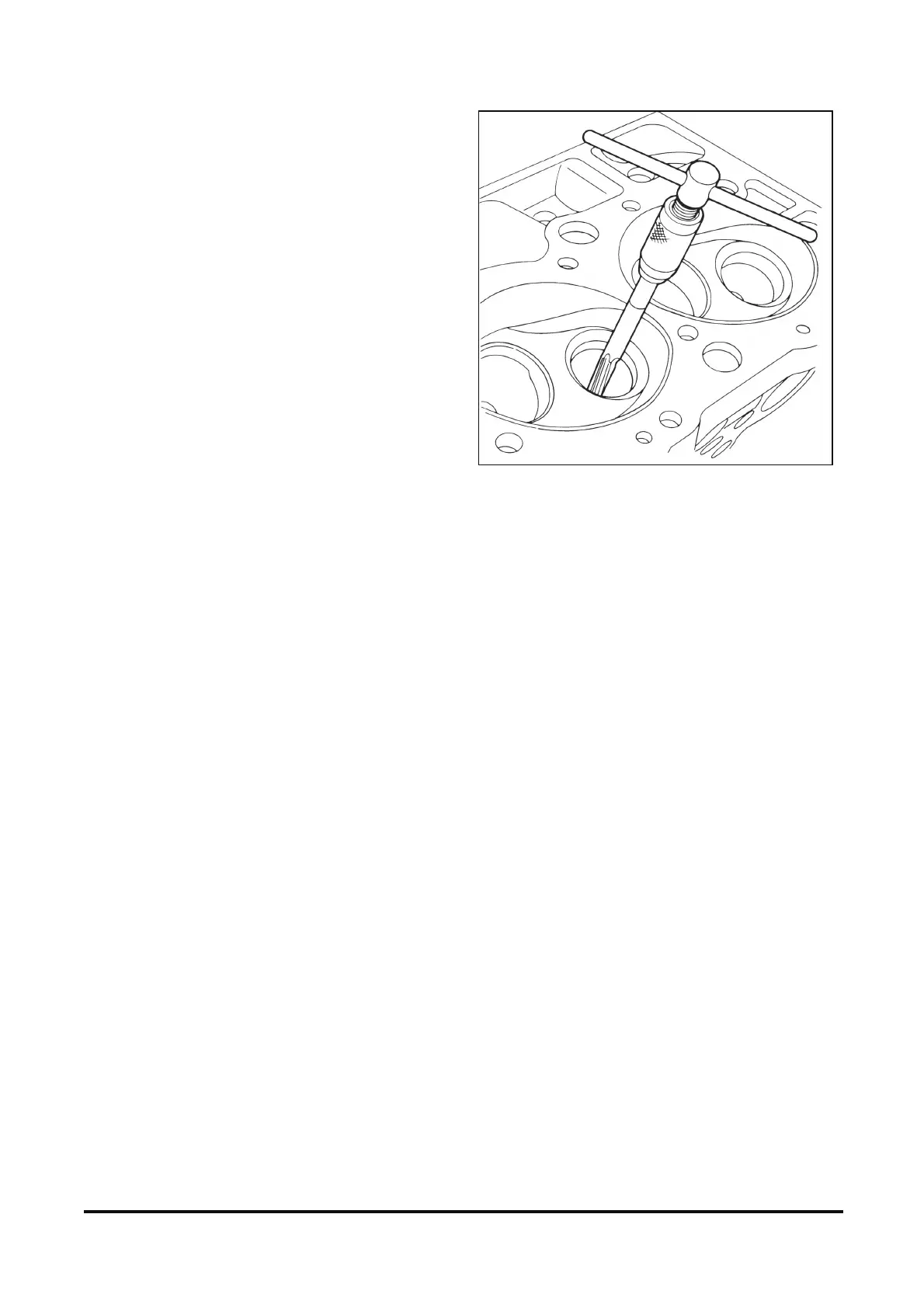

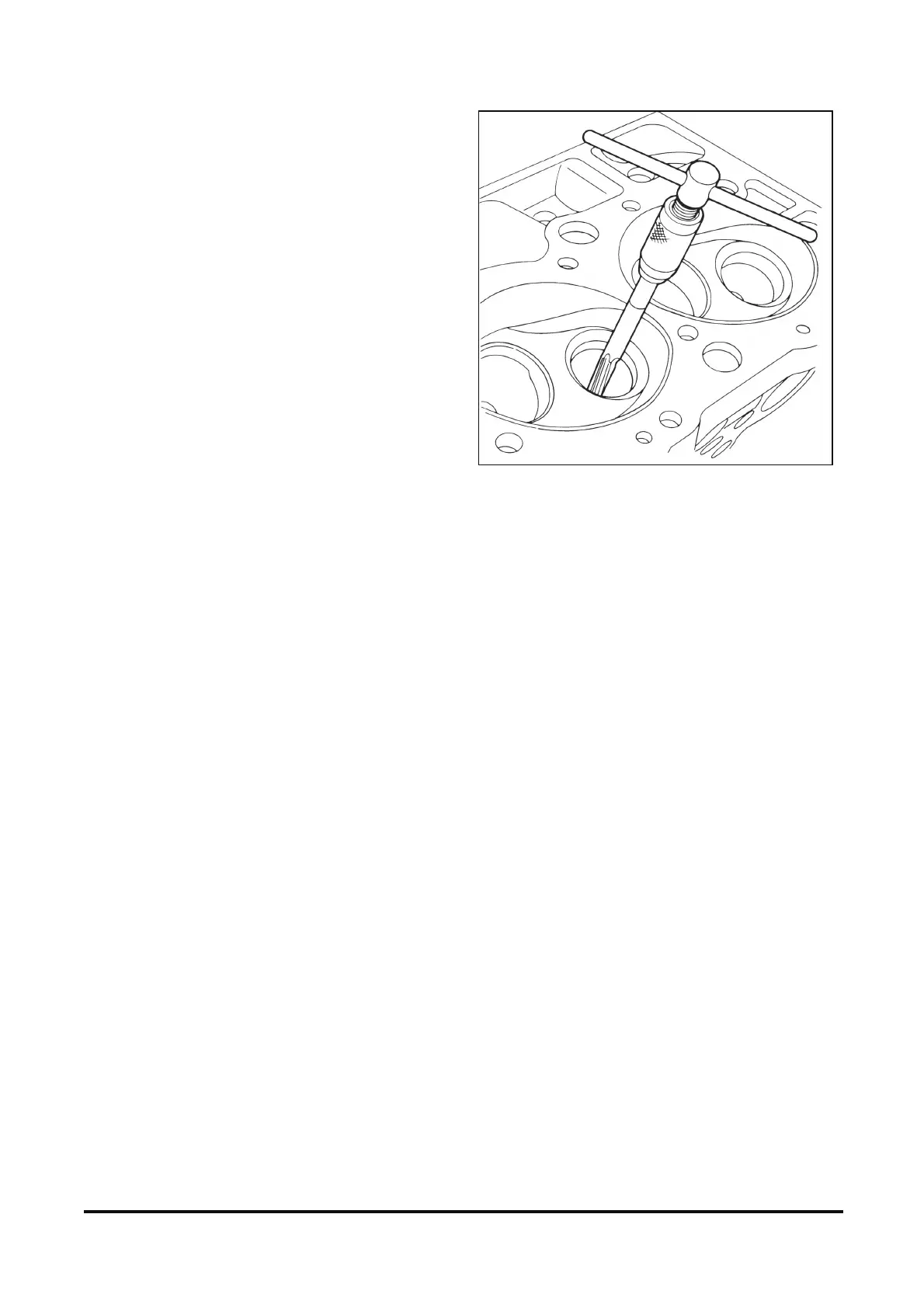

Reaming Valve Guide

The valve guides used in this engine are simply

holes bored in the cylinder head. The valve guides

are not replaceable.

If the valve stem-to-bore clearance as previously

measured is excessive, the valve guides should be

reamed and a valve with an oversize stem installed.

Oversize valves are available. Refer to “Specifica-

tions”.

Select a reamer that will provide a straight, clean

bore through the entire length of the valve guide

(figure 12-58).

Valve Rocker Arm Stud Replacement

Remove or Disconnect

1. Valve rocker arm stud by unscrewing.

Install or Connect

1. Valve rocker arm stud into cylinder head.

Tighten

• Rocker arm stud to 47 Nm (35 lb· ft.).

Figure 12-58 Reaming Valve Guides

Assembly

Figures 12-48, 12-49, 12-59 and 12-60

Install or Connect

1. Valves.

A. Lubricate the valve stems with clean engine

oil.

B. Insert the valves into the proper valve guides

until the face of the valve contacts the valve

seat.

2. Seal.

A. Install the seal over the valve stem.

B. Hold the valve against the valve seat.

C. Push the seal down the valve stem until it

bottoms out against the head.

3. Springs.

4. Valve spring cap.

A. Compress the valve spring using J 8062

(figure 12-48), enough so the lower valve stem

groove can be seen clearly.

B. Apply a small amount of grease to the area of

the upper valve stem groove.

C. Assemble the two valve keys into the upper

groove using the grease to hold them in place.

D. Release the compressor tool J 8062, making

sure the valve keepers stay in place.

E. Repeat the preceding steps on the remaining

valves.

Loading...

Loading...