1BHFt%3*45&&.7BQPSMPHJD*OTUBMMBUJPOBOE0QFSBUJPO.BOVBM

Float valve system

DI/RO water systems (except for steam injection) use a float valve

system to control water levels for optimum operating efficiency.

DI/RO systems are used where water/steam purity is important,

where demineralized water is needed to improve performance or

lessen maintenance requirements, or where a water source has

minimal or no conductivity, thus requiring a float rather than a

probe to sense water levels.

The float valve system consists of a fill float and a low water cutoff

float.

The fill float regulates how much water is added to the tank via a

float ball, float arm, and mechanical valve. The valve is adjusted to

fill the evaporating chamber within ¼" (6 mm) of the overflow port

allowing heated, and therefore expanded, water at startup to fill the

external P-trap.

The low water cutoff float has an electrical switch that closes when

a ready water condition is reached. This float switch provides low

water protection for the heating outputs. If the water falls below the

float, the heating outputs are disabled.

See “Chloride corrosion” Caution at left.

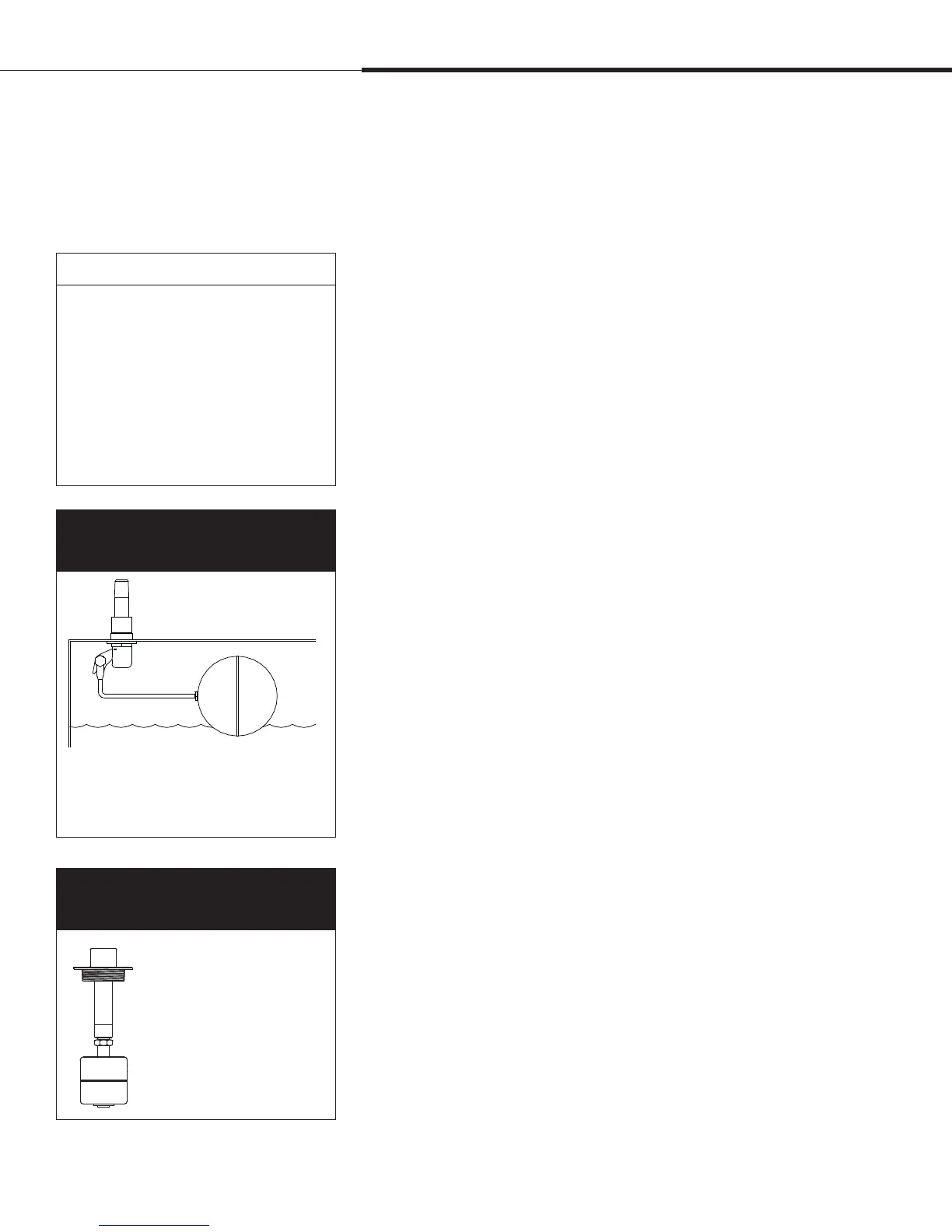

Figure 56-1:

Water level control for DI/RO

water systems

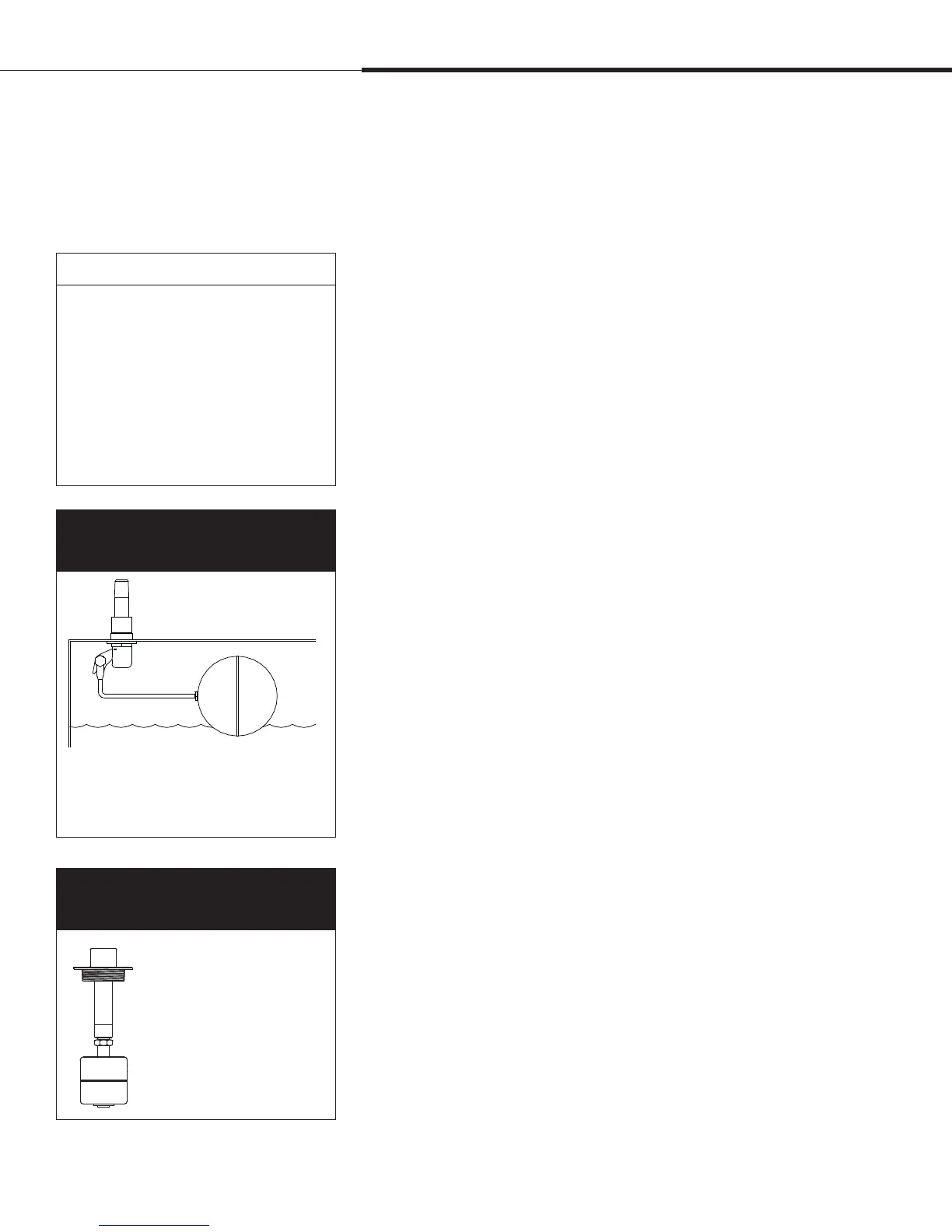

Figure 56-2:

Low water cutoff switch for DI/RO

water systems

8BUFSMFWFMDPOUSPM

Operation

Supply water connection

Float rod

Float ball

OM-7396

Humidifiers using DI/RO water control water

levels using a float valve and low-water

cutoff switch.

mc_052710_1644

A zero mark on top of the

float indicates proper float

placement on stem. Switch

is normally open when float

ball is at its lowest point on

the stem.

OM-3009

XT humidifiers do not use the float valve system

for water level control. See “Electrode steam

humidifiers” on Page 57.

CAUTION

Chloride corrosion

Damage caused by chloride corrosion is

not covered by your DRI-STEEM warranty.

Chloride corrosion can result from a

variety of causes, including, but not

limited to

t *NQSPQFSXBUFSEFJPOJ[BUJPOQSPDFTTFT

t *NQSPQFSXBUFSTPGUFOJOHQSPDFTTFT

t )VNJEJmFSTTVQQMZXBUFS

Loading...

Loading...