60

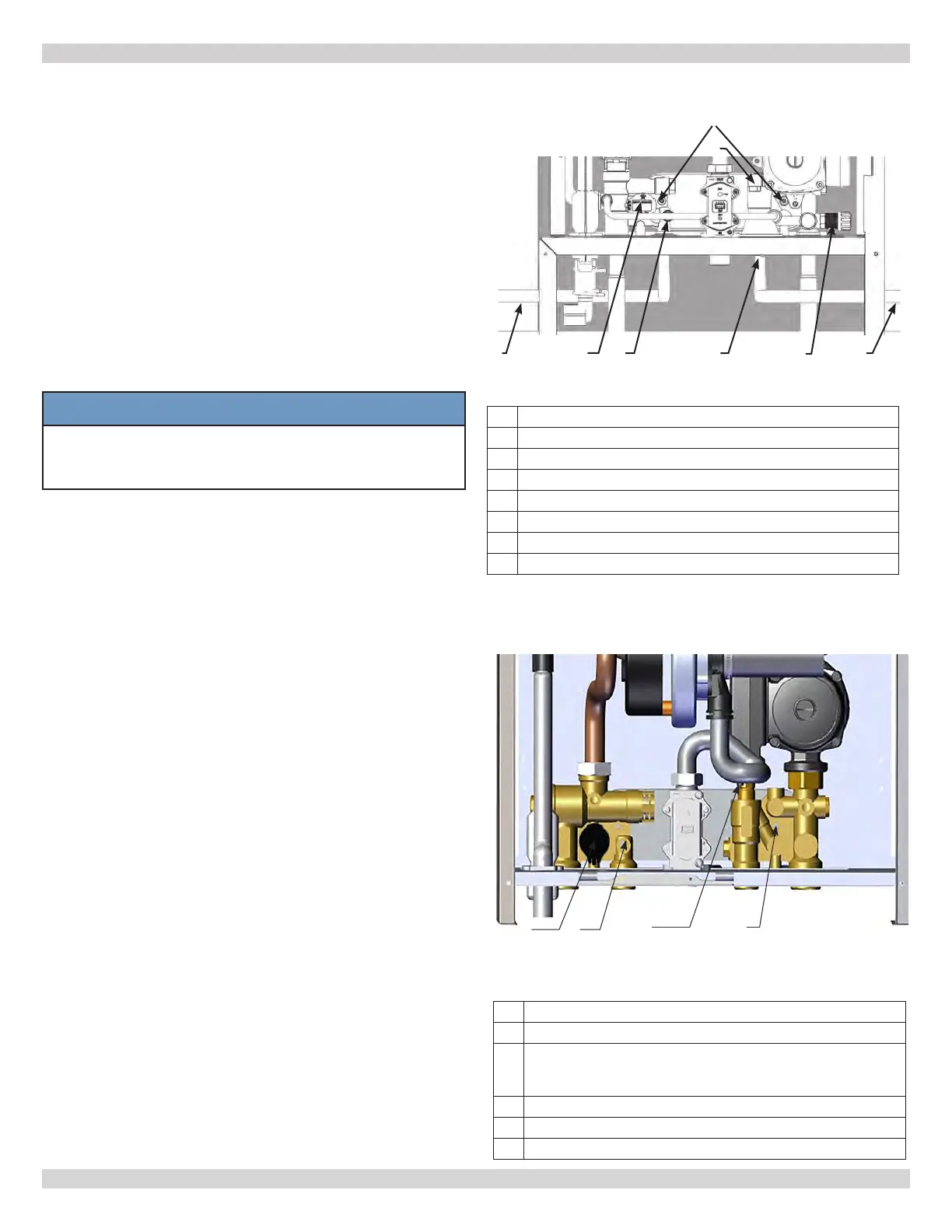

11.6 Hydraulic Unit (DHW)

For special areas, where water is harder than 200 ppm

or 12 grains/ gallon, install polyphosphate dispenser or

equivalent treatment system, compliant with current

regulations.

LEGEND

A DHW Exchanger Screw

B DHW Priority Sensor

C Boiler/System Drain Tap

D

Controlled Fast Fill

E DHW Temperature NTC Probe

F

G DHW Cold Inlet

H DHW Outlet

11.7 Cleaning The Cold Water Filter

hydraulic assembly (B). To clean:

• Drain domestic hot water system. (C - 115 & 150)

•

• Remove nut on DHW priority sensor unit using 18

mm wrench. (B)

•

• Remove any impurities.

11.8 Final Commissioning

• Allow heating system to heat. Balance the system

supply and return pipes at the boiler.

• Check system for proper volume and pressure. See

page 4 for acceptable volume and pressure.

•

•

heating return and supply water isolating valves.

• Repressurize the system.

11.9 Final Assembly

• Place front jacket in position over boiler. Secure in

position at top using screws previously removed.

• If boiler is to be left in service with the User, set

controls and room thermostat.

• If boiler is not to be handed over immediately,

supply.

• If there is possibility of boiler being left during frost

conditions drain boiler and system. See section

11.3 Component Replacement and Cleaning.

Manufacturer recommends attaching a label to the

boiler drawing attention to the fact that the system

has been drained.

Model DCCF-115 & 150

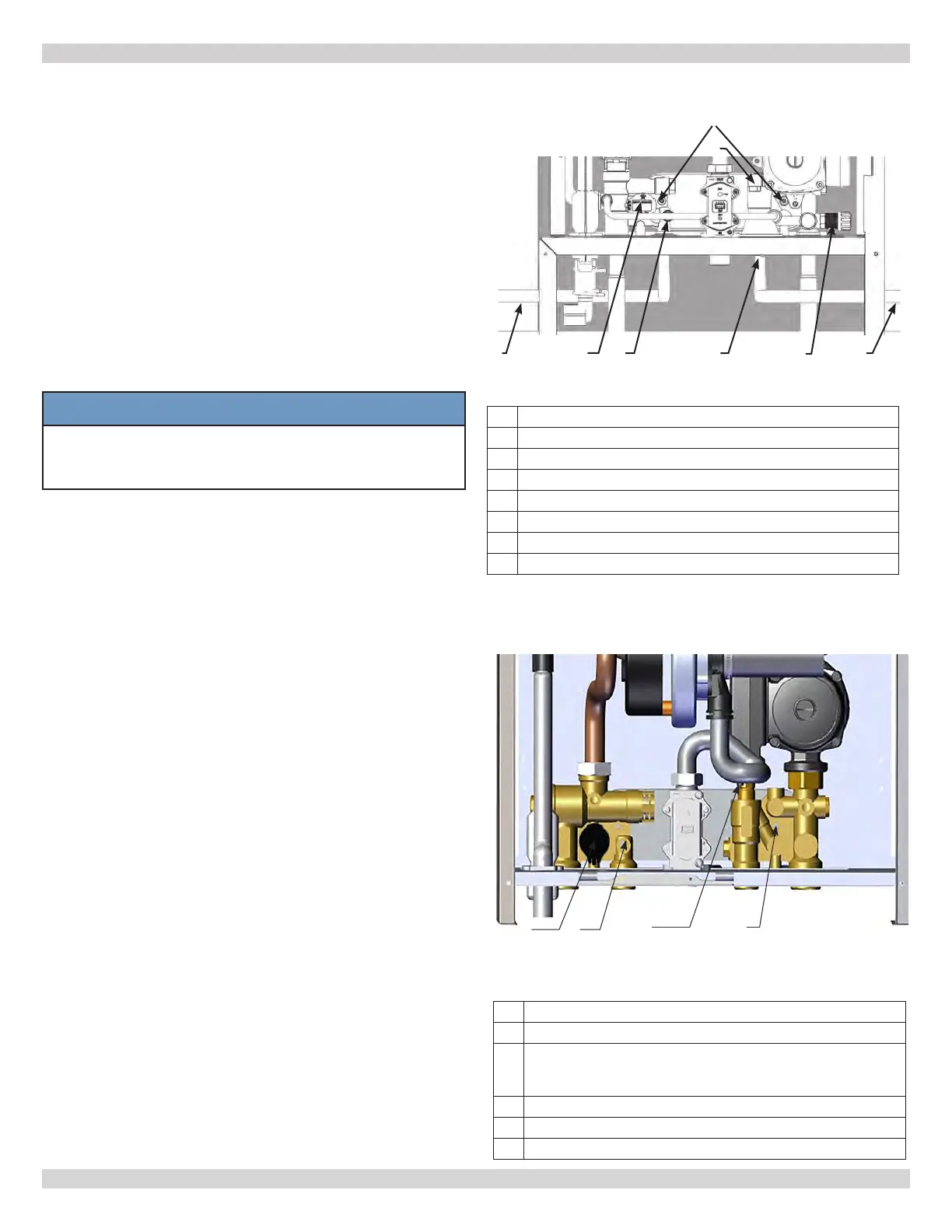

Hydraulic Assembly (Combi-150)

NOTICE

When replacing and/or cleaning “O-rings” on

hydraulic assembly (DHW), use only Molykote

111 as a lubricant, not oil or grease.

11 - GENERAL MAINTENANCE AND CLEANING

HH GG

LEGEND

A DHW Exchanger Fixing Screw

B DHW Priority Sensor With Filter

C

Boiler/System Drain Tap (150 Unit Only)

(C-1 & C-2: Access To Tap C - Bottom Of

Boiler)

D Boiler / System Filling Tap (150 Unit Only)

E DHW Temperature NTC Probe

F

Model DCCF-205

B

A

Hydraulic Assembly (B)

F

E

FF EE DD CC

AA

BB

240013375 REV A, [07/01/2021]

Loading...

Loading...