Check Local Check Local

Codes For Codes For

Maximum Maximum

Distance To FloorDistance To Floor

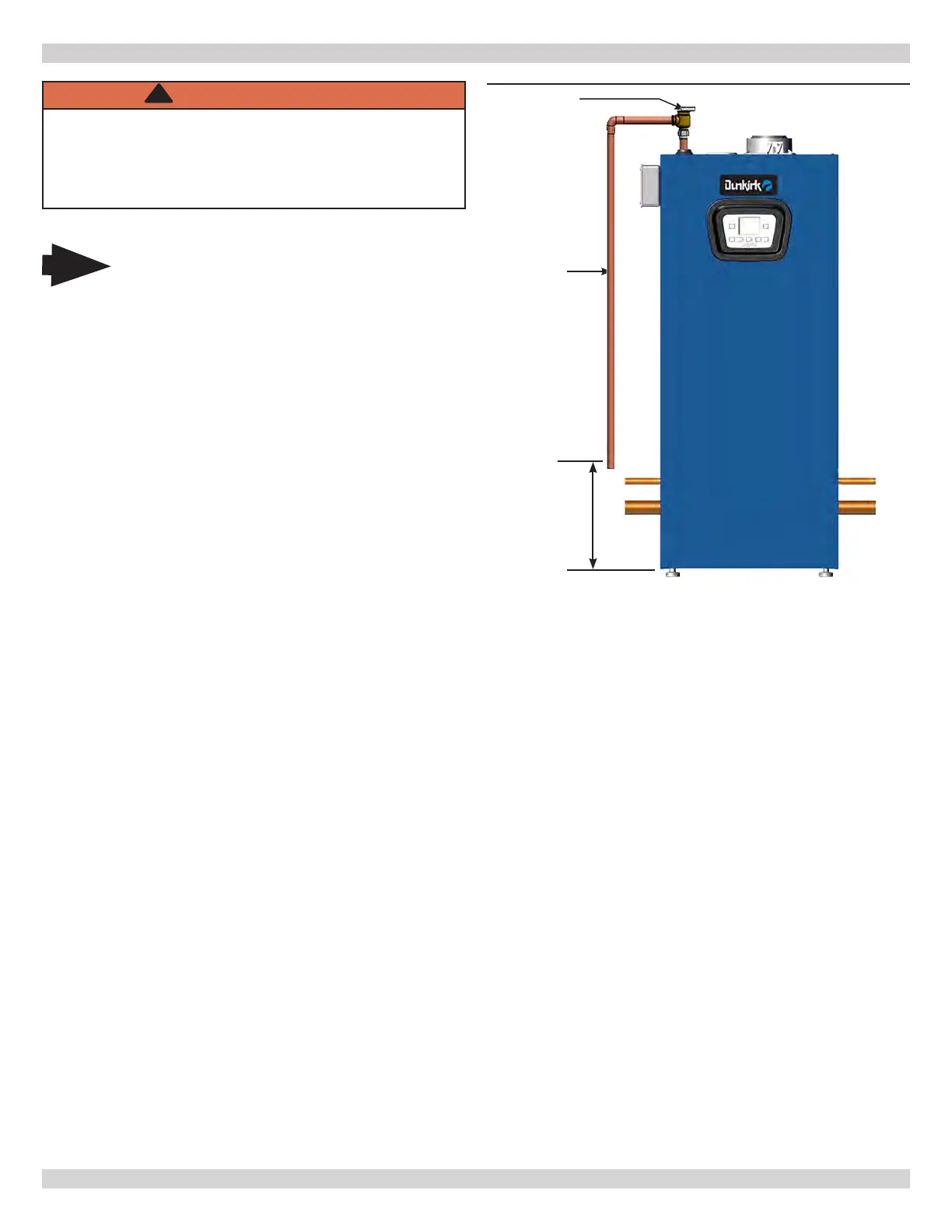

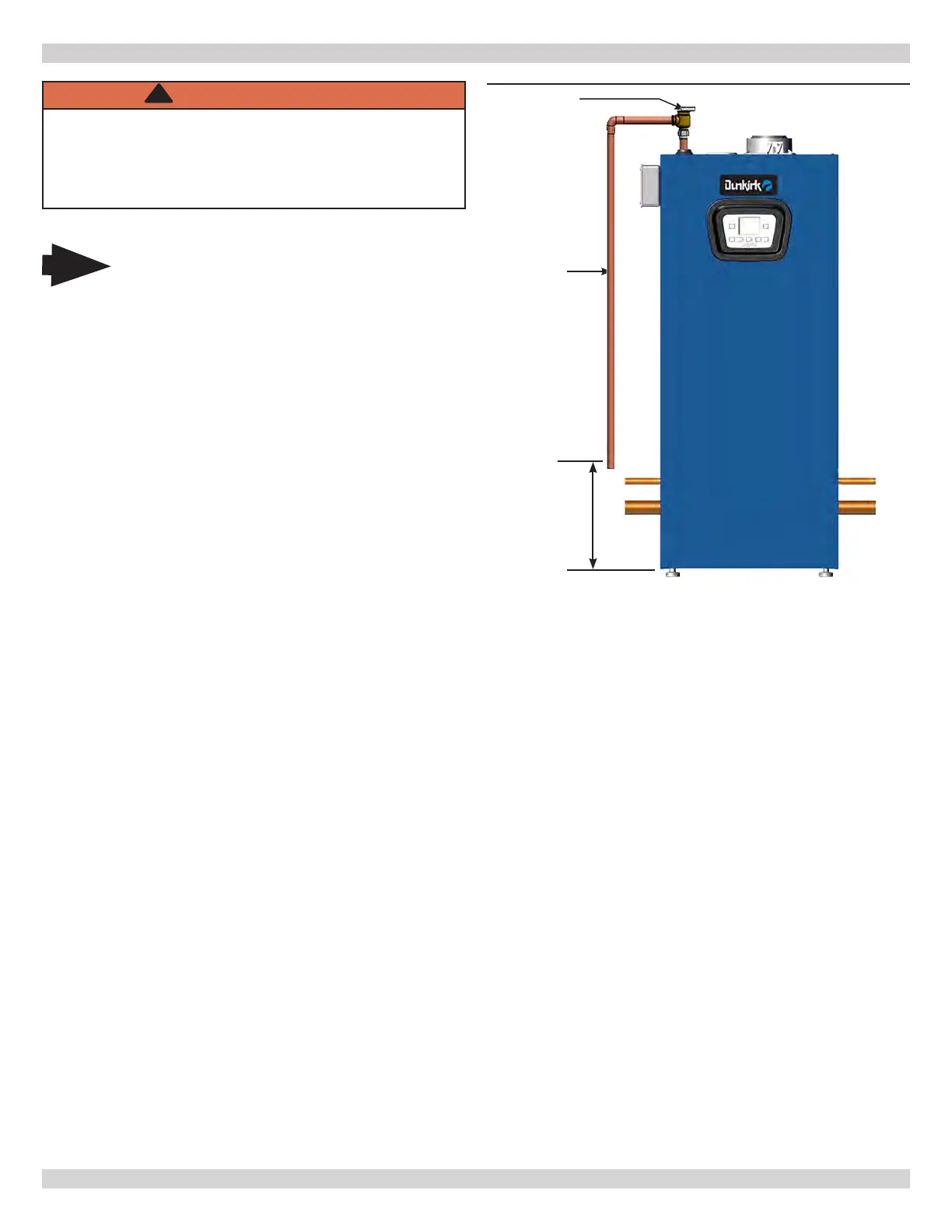

Safety Relief

Valve

Do not use

plastic pipe see

Warning above.

FIGURE 6-1 Safety Relief Valve

31

6.3 Safety Relief Valve and Air Vent

•

provided with boiler. See Figure 6-1.

• Install safety relief valve with spindle in vertical

position.

•

safety relief valve.

• Install discharge piping from safety relief valve.

Do not use plastic pipe.

• Use ¾" or larger pipe.

• Use pipe suitable for temperatures of 375°F

(191°C) or greater. Do not use plastic pipe on

safety relief valve.

• Individual boiler discharge piping shall be

independent of other discharge piping.

• Size and arrange discharge piping to avoid

reducing safety relief valve relieving capacity

below minimum relief valve capacity stated on

rating plate.

• Run pipe as short and straight as possible to

location protecting user from scalding and

properly drain piping.

• Install union, if used, close to safety relief valve

outlet.

• Install elbow(s), if used, close to safety relief

valve outlet and downstream of union (if used).

• Terminate pipe with plain end (not threaded).

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Use pipe suitable for temperatures of 375°F

(191°C) or greater. DO NOT use plastic pipe.

Install discharge piping per these instructions.

!

6 - HYDRONIC PIPING

6.4 Trim Piping

• Temperature - Pressure Gauge. Install temperature

pressure gauge using tee and bushing provided in

near boiler piping on supply side. See Figure 6-2.

• Some boiler models may have integral drain valve

located inside jacket directly underneath pump.

Install external drain valve as required.

6.5 System Piping

• Ensure plugs are removed from boiler water

connections.

• See Figure 6-5 for basic system piping

•

prevention device.

• Single boiler system. See Figures 6-2, 6-5, for

general guidance. Additional considerations:

• Boiler control only supports integrated pump.

Installer responsible for integration of multiple

external control.

• Boiler control allows domestic hot water

prioritization.

•

•

• Manufacturer recommends installing an isolation

and purge valve to use during commissioning to

ensure the boiler does not shut down due to over-

• Do not install isolation valve between boiler and any

• If soldering piping to boiler, avoid over heating and

damaging seals and gaskets.

• Connect system valve pipe work to the boiler.

• Route pressure relief valve discharge piping to the

See Figure 6-1.

• Verify all drain valves are closed.

When installing safety relief valve it must

be installed in a vertical position with

spindle at top.

Note

240013375 REV A, [07/01/2021]

Loading...

Loading...