2-20

Chapter 2 Basic Operation

7-4. Adjusting the belt stacker

Do not sit on the stacker tray.

Do not push the stacker tray.

Do not put a heavy load on the stacker tray.

When booklet length is short or thick, booklets may jam at the infeed section of the belt stacker or may not

be stacked in a row with each booklet slightly overlapped. In that case, adjust the belt stacker following the

procedures below.

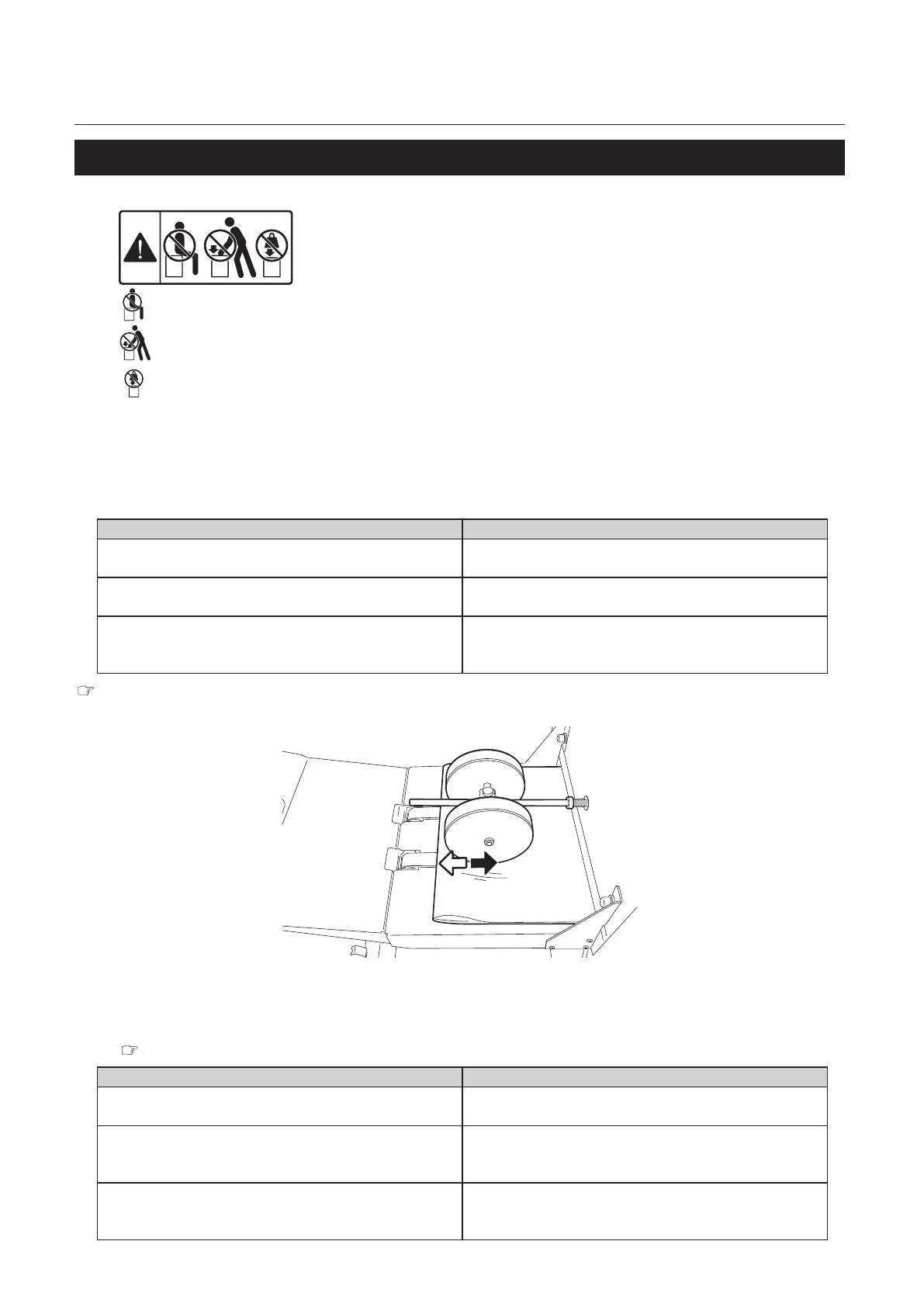

7-4-1. Adjusting the paper guide roller

Condition Solution

The booklet is thick and cannot pass under the paper

guide roller.

Move the paper guide roller behind the thickest part

of the booklet (the direction of A in the gure below).

The booklet is thin and cannot pass under the paper

guide roller.

Move the paper guide roller to the stacker tray side (the

direction of B in the gure below).

The booklets cannot be stacked in a row with each

booklet slightly overlapped because of the short

length.

Move the paper guide roller to the machine side (the

direction of A in the gure below).

”3-3. Adjusting the position of the paper guide roller” (p.2-11)

AB

7-4-2. Adjusting the operating time of the belt of the belt stacker

After following “7-4-1. Adjusting the paper guide roller,” adjust [Stack Oper T] in the function menu on the

control panel referring to the condition below.

”4-2-2. Function Menu” (p.1-15)

Condition Solution

Paper jam occurs when booklets are ejected to the

belt stacker.

Increase the value for [Stack Oper T] to make the

operating time of the belt longer.

When ejected to the belt stacker, the booklet hits the

trail edge of the previous booklet or turns up the cover

of the previous booklet.

Decrease the value for [Stack Oper T] to make the

operating time of the belt shorter.

The booklets cannot be stacked in a row with each

booklet slightly overlapped because of the short

length.

Decrease the value for [Stack Oper T] to make the

operating time of the belt shorter.

Loading...

Loading...