S801+ Operating Configuration

28 S801+ Soft Starter MN03900002E—November 2012 www.eaton.com

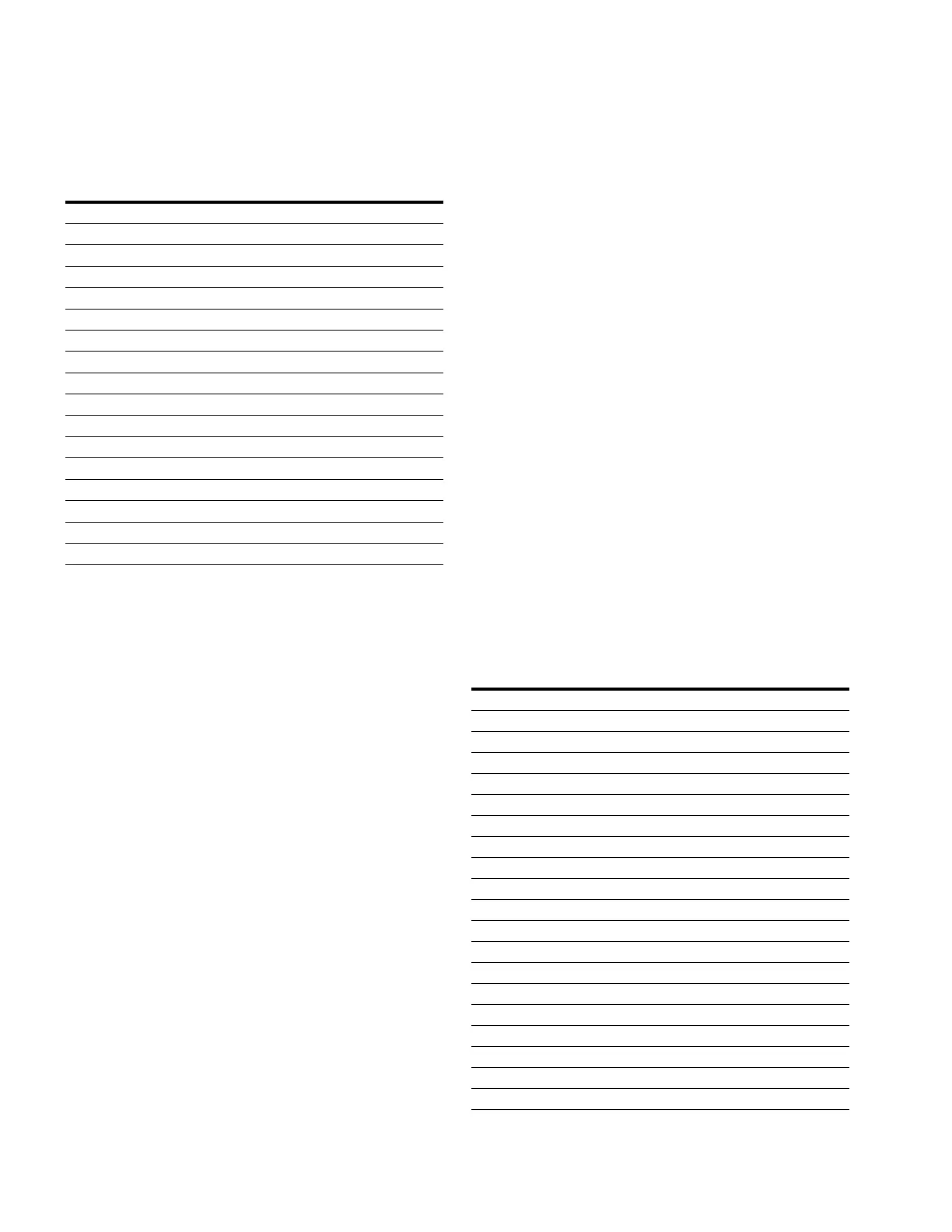

FLA Potentiometer Setting Values

Protection Parameters

In addition to motor overload protection, the S801+ has

many programmable features designed to protect the motor.

●

Incoming Line Phase Reversal, Loss, Imbalance, Over

Voltage, and Under Voltage trips.

●

Selectable Overcurrent trip levels.

●

Stall and Jam trips.

A Phase Reversal Fault is a likely fault condition on new

installations. It can be addressed by disabling phase rotation

monitoring, or removing Mains power and switching the

incoming line connections at L1 and L2 of the S801+.

Apply the Mains voltage and verify that no fault is present.

The S801+ indicates faults with a Flash Code on the CIM.

When a Fault Trip occurs, the S.S. Trip LED will illuminate

along with the corresponding dedicated LED if applicable. If

the Fault is no longer active, the S801+ may be Manually

reset by pressing the reset button on the face of the soft

starter.

Fault Trips

The S801+ is configured from the factory with all protection

parameters enabled. It is recommended that all appropriate

protection parameters are enabled for proper operation and

protection of the soft starter and the load.

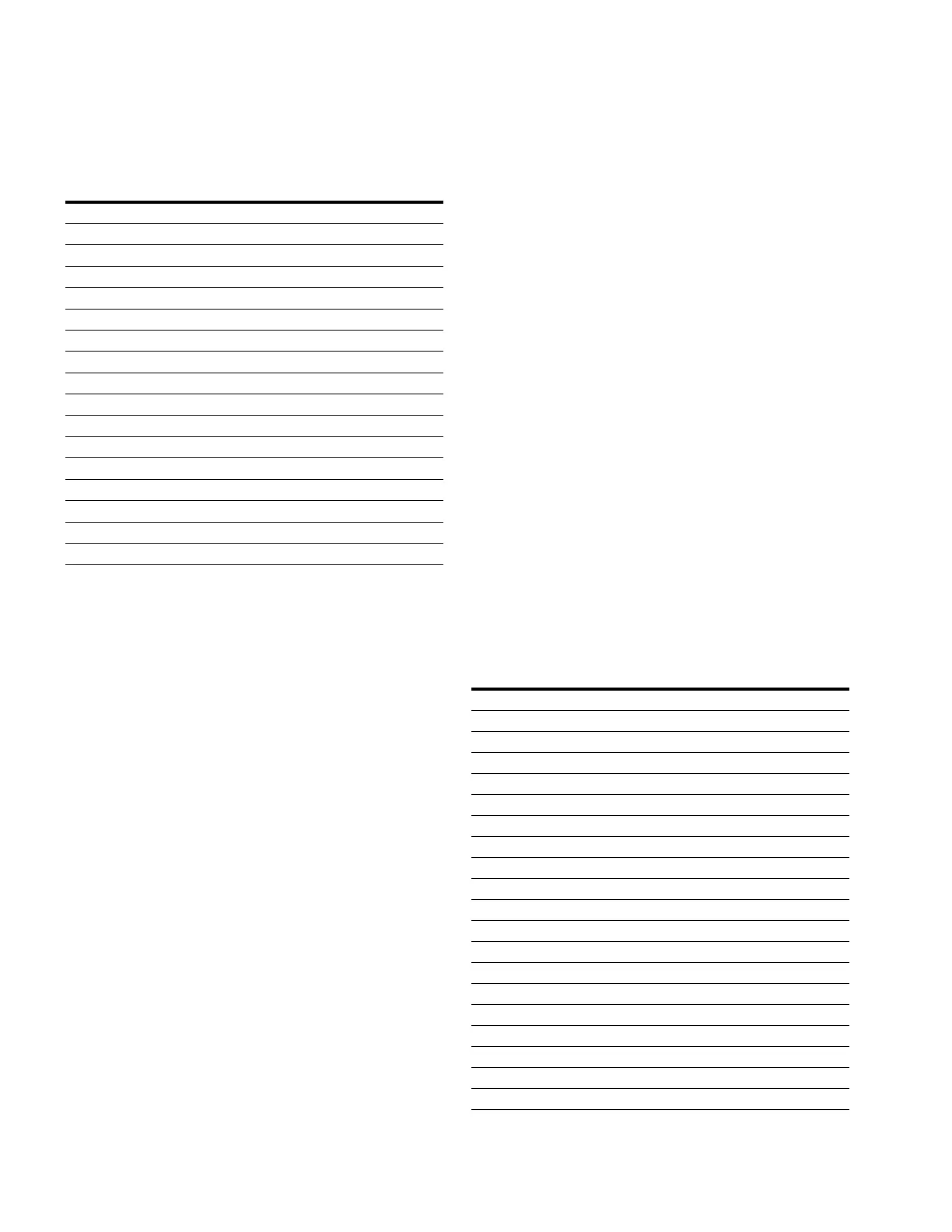

Fault Codes

For additional details on troubleshooting fault codes and

fault conditions, please refer to Troubleshooting and

Appendix E.

To obtain the fault flash codes from the CIM, hold the RESET

button (located below the CIM) down or apply 24 Vdc to

terminal 4 and count the number of times all the LEDs on the

CIM flash.

For example, if you see three flashes, and then two more

flashes after a short pause, the flash code is 32.

The CIM can provide multiple flash codes, if more than one

error condition caused a stop. Once you see the same flash

code repeated, you have seen all the flash codes for the error

conditions that caused the stop.

For example, if you see three flashes, a pause, then two

flashes, a slightly longer pause, then four flashes, a pause,

then one flash, the flash codes are 32 and 41.

If you then see three flashes, a pause, then two flashes, you

are seeing the first code again. This means you have seen all

the flash codes for this stop.

You may now release the RESET button or remove 24 Vdc

from Control terminal Block Terminal 4.

Note: If an overload trip has occurred, 24 Vdc power must

be applied to allow the overload thermal memory to

reset. Depending on the overload history prior to the

latest trip, this may be as long as 9 minutes.

A list of flash codes and the faults they represent is shown

below.

Fault Codes

Catalog

Number

Potentiometer Setting

I

FLA

ABCDDefault

S801N37… 11 19 27 37 11

S801N66… 20 35 50 66 20

S801R10… 32 56 80 105 32

S801R13… 42 73 104 135 42

S801T18… 56 97 138 180 56

S801T24… 75 130 185 240 75

S801T30… 95 164 233 304 95

S801U36… 112 194 276 360 112

S801U42… 131 227 323 420 131

S801U50… 156 270 384 500 156

S801V36… 112 194 276 360 112

S801V42… 131 227 323 420 131

S801V50… 156 270 384 500 156

S801V65… 203 352 501 650 203

S801V72… 225 390 555 720 225

S801V85… 265 460 655 850 265

S801V10… 320 547 773 1000 320

Fault Code Fault

11 Thermal Overload

12 Motor Stall (LED)

13 Motor Jam (LED)

14 Phase Reversal (LED)

15 Pole Over temperature

16 SCR Failed to fire

22 Phase loss (LED)

23 Internal bypass contactor dropout

24 SCR/Contactor overcurrent

25 Phase imbalance

26 Non-volatile memory error

31 Zero voltage cross failure

32 Shorted SCR, Phase loss, Load disconnect

33 Load disconnect

34 SCR instantaneous overcurrent

41 24V power supply low

42 Timer system fault

43 Watchdog reset occurred

44 PLL (DSP) fault

45 Illegal address (DSP)

Loading...

Loading...