417102012_LMI02.doc - 64 - Rev. 9-07.08

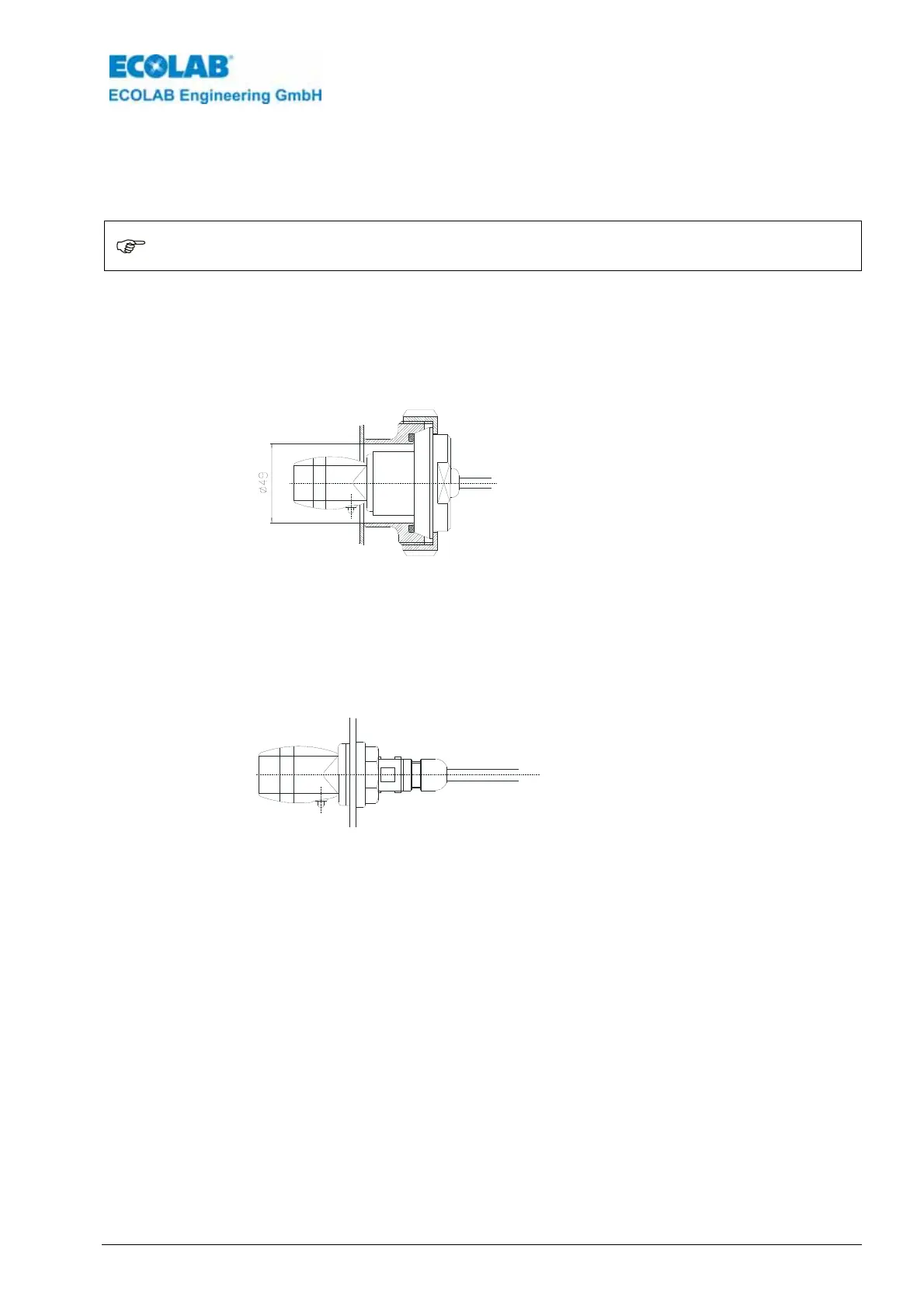

6.1.3.1 Tank wall installation by means of welded-on fittings in acc. with DIN 11851

Drill a hole

with a diameter of 49 mm at the intended position in the tank wall.

The welding fitting has to be welded professional.

NOTE

Negligence in selecting the appropriate material for the connection between the tank wall,

welding electrode, welded-on fittings (material 14301) and post-treatment of the weld

seams can cause corrosion in the weld seam.

Insert sealing gasket on the welded-on fitting.

Place the conductivity probe with adapter from the outside of the tank into the fitting and fix

into place with a retaining nut.

The orientation of the measuring hole can be checked with the aid of the arrow marked on

the back of the conductivity probe.

fig 6.2

Type: Milk pipe fitting (DIN 11851)

Diameter: DN 50

Item no. for conductivity probe 0.2m in PEEK

with PVDF adapter: 287604

Item no. for conductivity probe 0.2m in PP

with PP adapter: 287622

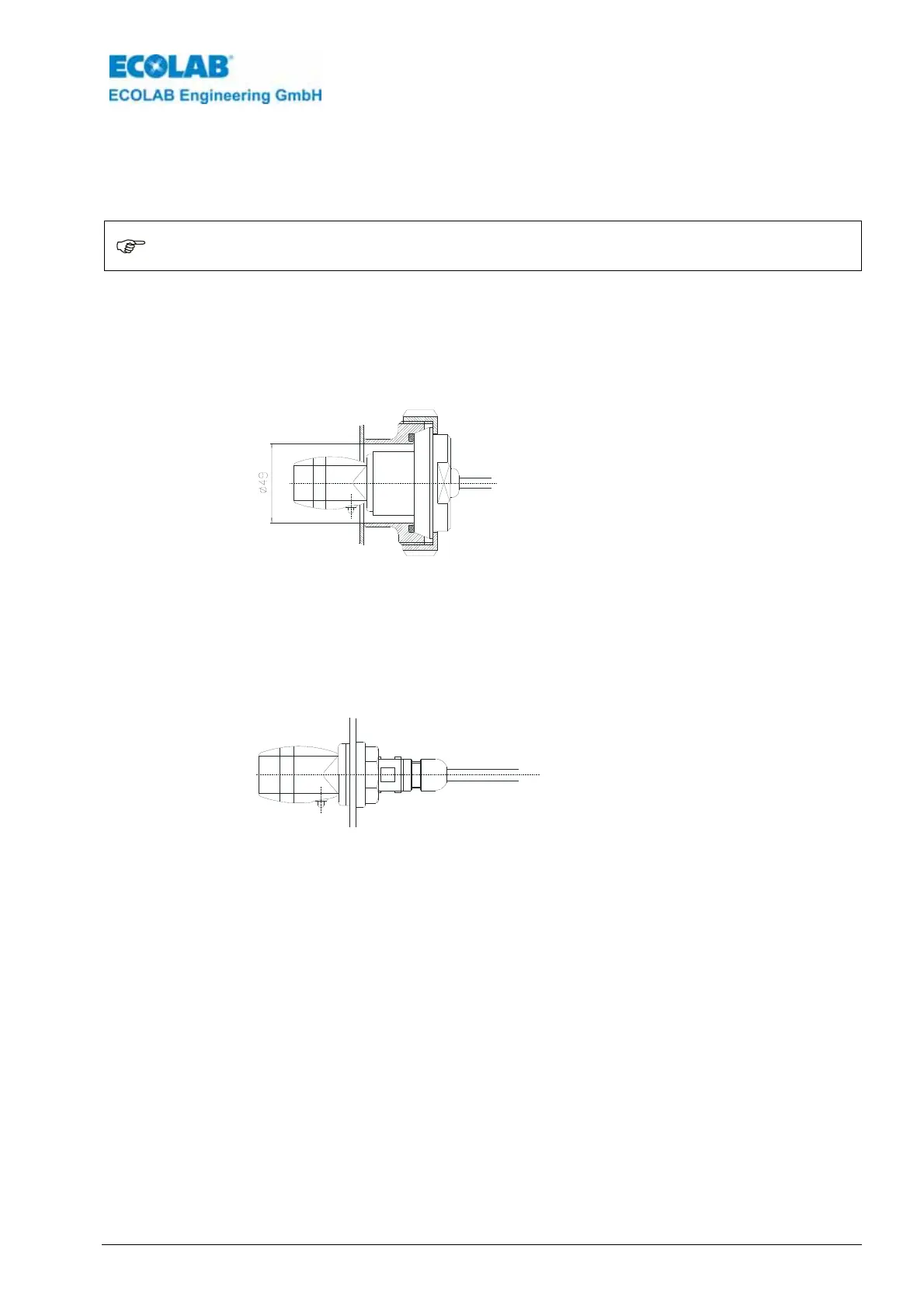

6.1.3.2 Direct tank wall installation by means of retaining nut (for straight tank wall)

Drill a hole

with a diameter of 21 mm in the tank wall at the intended position.

Place the conductivity probe onto the flat gasket ring on the hole from inside the tank.

Fix the conductivity probe into place with a retaining nut and inlaid sealing gasket.

fig 6.3

Type: Screw connection

Through hole: 21 mm

Item no. for

conductivity probe 0.2m in PP

287413

Loading...

Loading...