417102012_LMI02.doc - 87 - Rev. 9-07.08

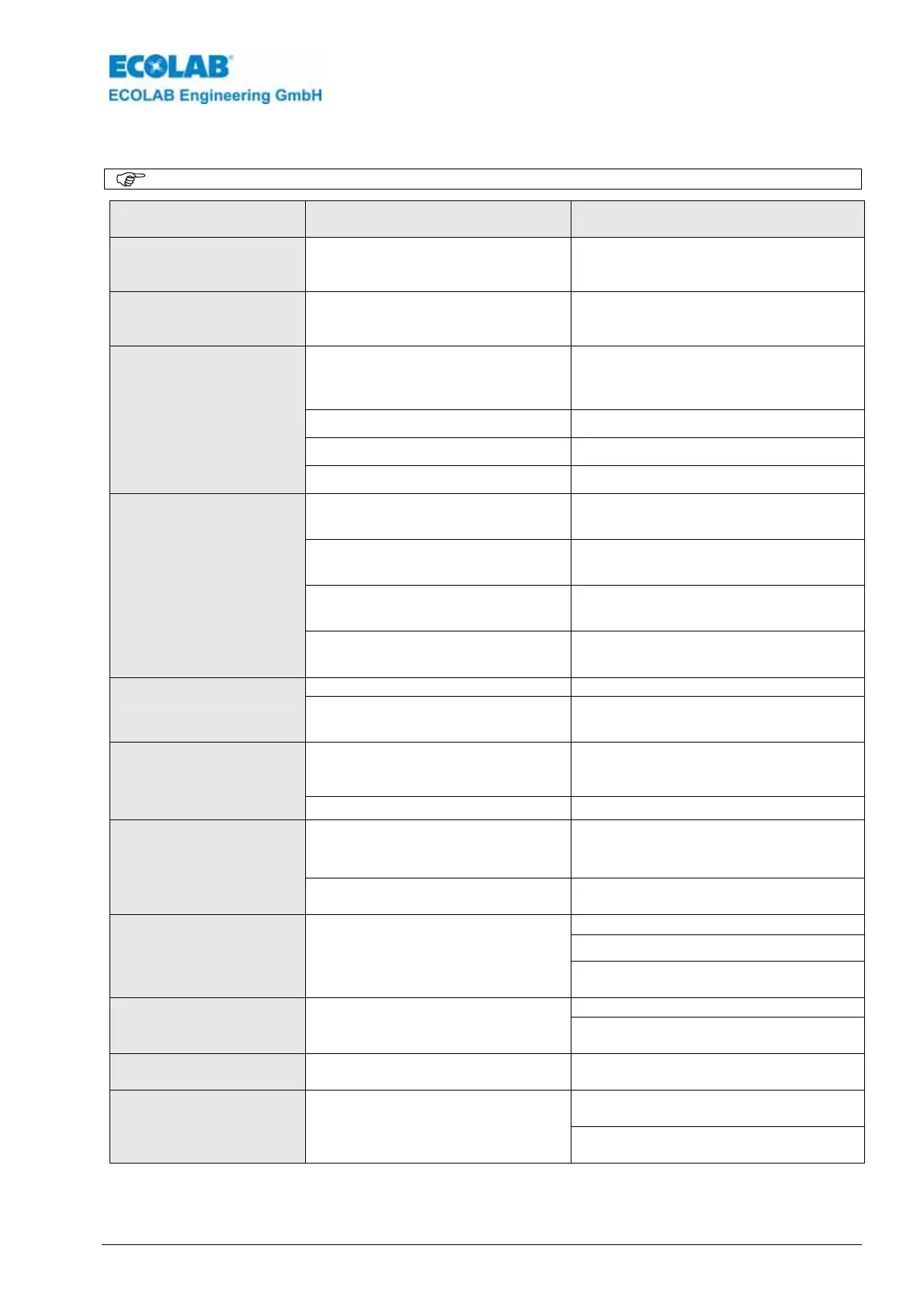

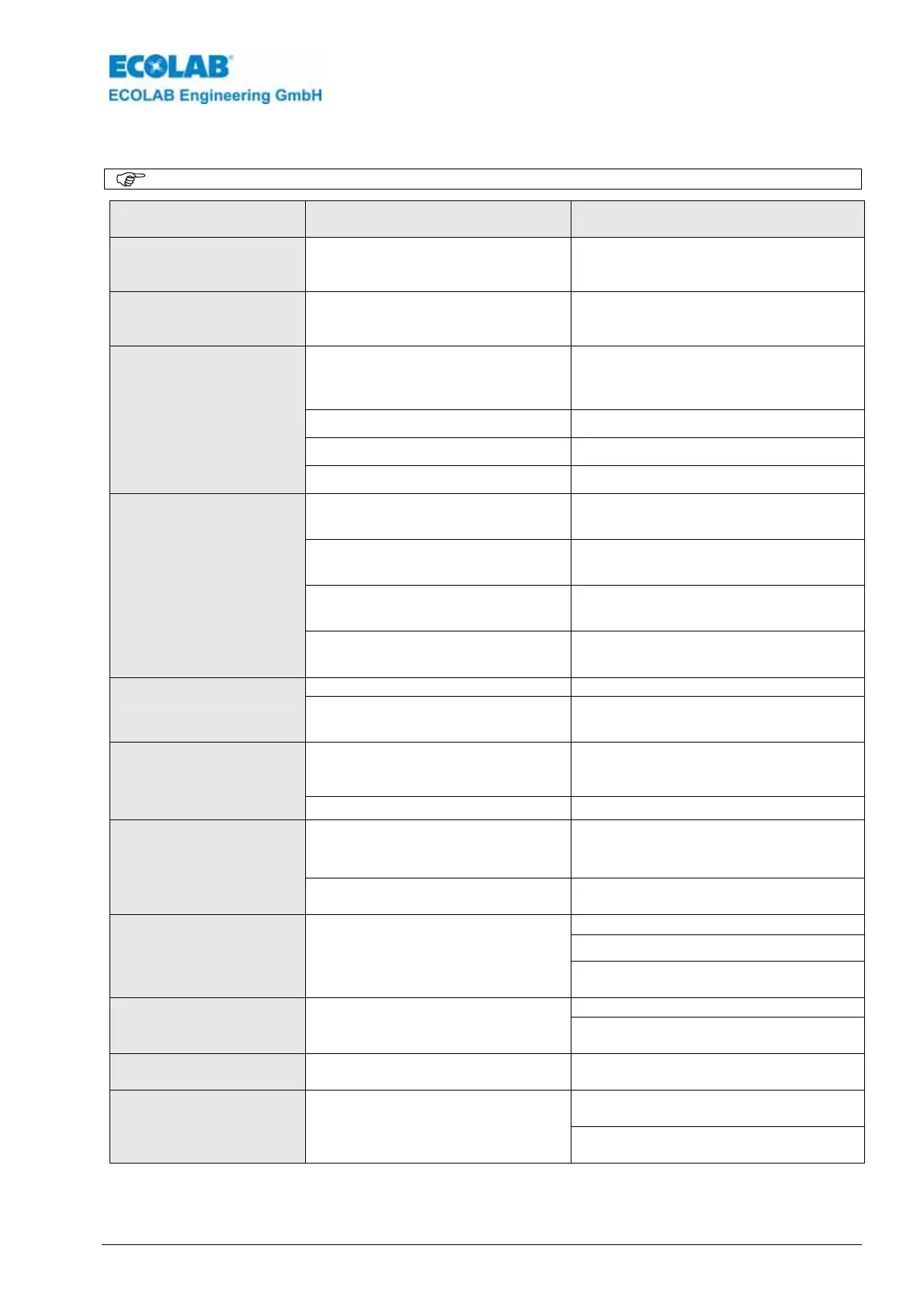

10 Troubleshooting

NOTE

A “SYSTEM FAULT” is only confirmed after switching the instrument off and on again.

Fault symptom or

display

Cause/fault Remedy

No display

- Display does not light up, no

supply voltage or the fuse is

defective

- Check if there is supply voltage or

check that the fine wire fuse is OK.

Change fuse if necessary.

Conductivity display

instable

- Air lock in the installation area of

the conductivity probe

- Check for air bubbles or insufficient

filling of pipes, follow

recommendation

- Metering enable input is not

closed

- Check the metering enable

connection on the instrument and

system

- Rated value has changed - Correct rated value setting

- Product storage container empty - Check level and level indicator

No metering in spite of

concentration undercut

- Max. metering time has expired - Check metering time limit

- Release signal “VD start” is not

available

- Check release signal to the system

- Metering enable is also active for

pre-metering

- Check metering enable signal

- Product storage container is

empty

- Check level and level indicator

Pre-metering

does not function

- Delay time for pre-metering has

been set

- Check time setting if necessary.

- Detergent storage unit is empty - Connect new container

NO DETERGENT

CHANGE CONTAINER

- Suction lance defect

Connection cable defect

- Replace suction lance

- Alarm delay time t max.

(DETERGENT DELAY TIME) set

too short

- Change alarm delay time

NO DETERGENT

CHECK METERING

- Metering pump is defective - Check metering pump (vent)

- Alarm delay time (detergent

overdose delay) is set too short

(local concentration overrun)

- Change alarm delay time

DETERGENT

OVERDOSAGE

- Relay for activation of “detergent

metering” output defective

- Return instrument for repair

- Check heating device

- Change the temperature limit

LOW

TEMPERATURE

- This alarm appears as soon as

the wash tank temperature drops

below the preset limit and the

delay time for the alarm expires.

- Change the alarm delay time if

necessary

- Check connector

CHECK

CONDUCT. PROBE

- Conductivity probe or connecting

cable defective. Connector not

correct

- Change the conductivity probe if

necessary

SYSTEMS FAULT

MEMORY

- Data in memory is incorrect - Return instrument for repair

- Ensure that connector is correctly

connected.

SYSTEM FAULT 9

- Communication between the

electronic boards has been

interrupted

- Return the instrument for repair if

alarm message persists.

Loading...

Loading...