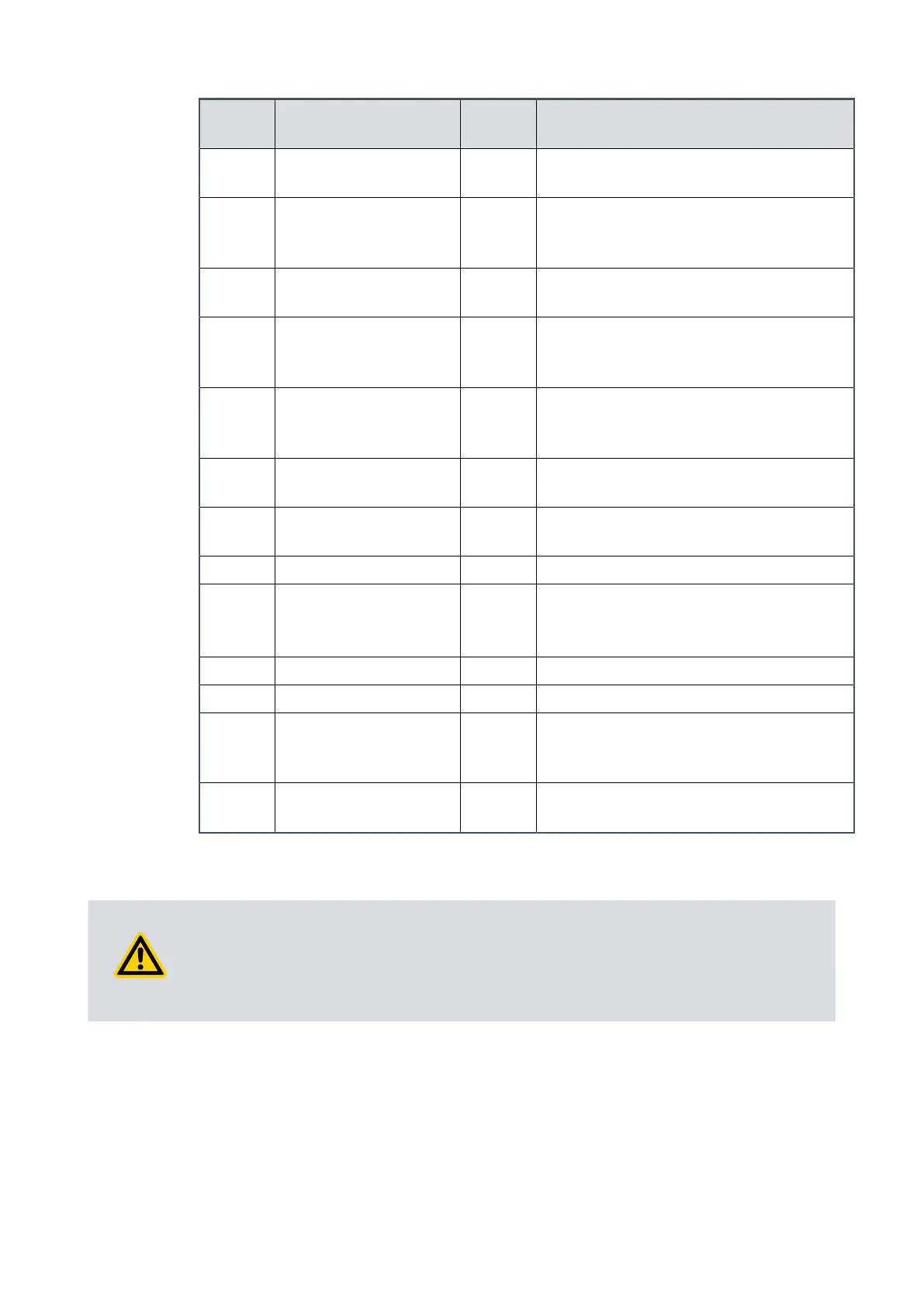

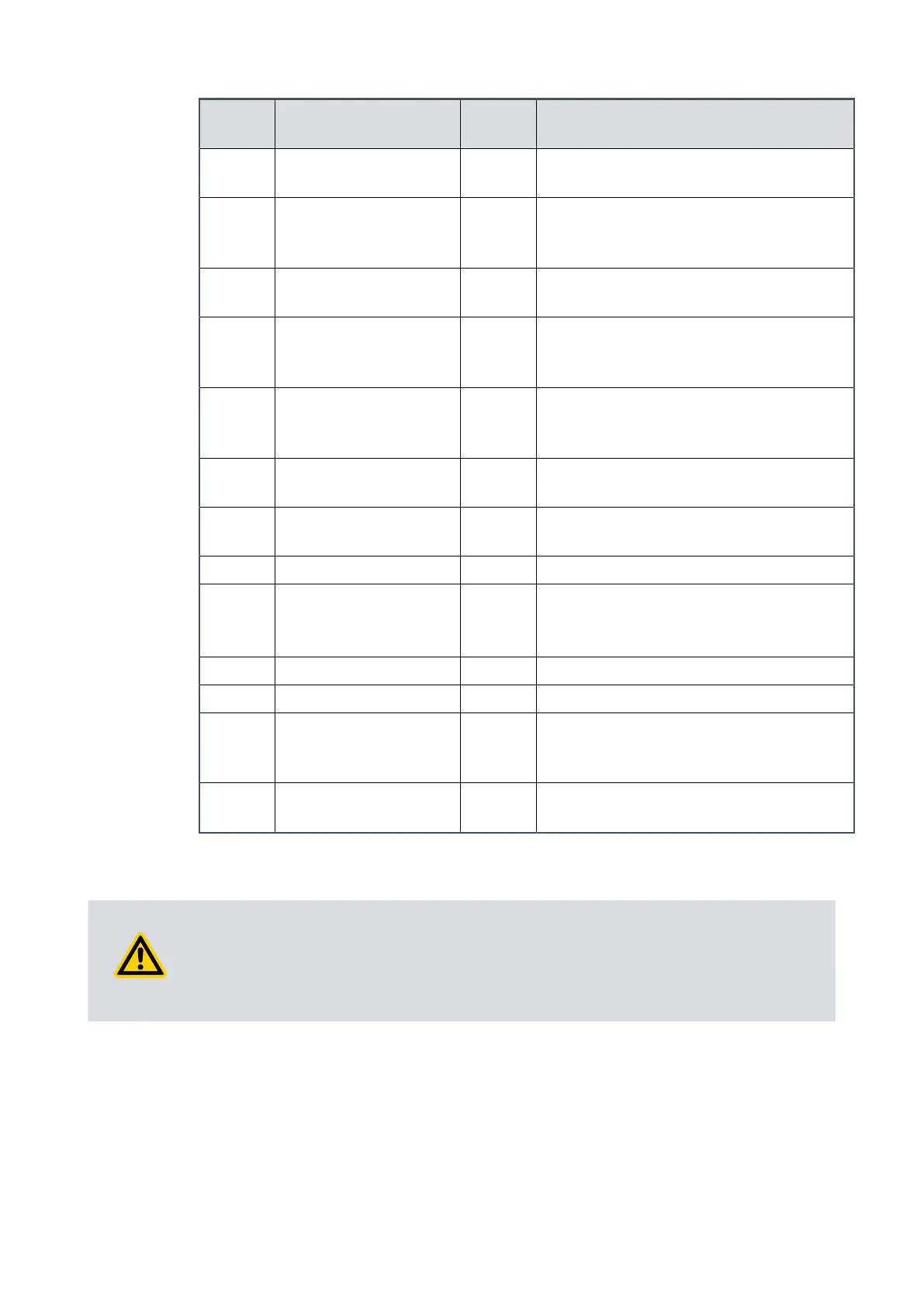

Pin

number

Signal Polarity Use

3 Start/Stop – control in-

put

- Connect to pin 2 (0 V) to start the pump

s

ystem.

4 Standby – control in-

put/serial-RX/RS-485 A-

- Connect to pin 2 (0 V) to enable standby

speed when the serial enable control in-

put is inacve.

5 Serial enable – control

input

- Connect to pin 2 (0 V) to enable serial

communicaons.

6 RS-232/RS-485 – control

input

- Default c

onguraon is RS-232 with pin 6

disconnected. Connect to pin 2 (0 V) to

enable RS-485 serial communicaons.

7 Fail – status output/

Serial-TX/RS-485 B+

- Logic high when a fail/fault condion ex-

ists and the serial enable control input is

inacve.

8 0 V control reference - 0 V reference for all control and status sig-

nals listed within this table.

9 Analogue speed – con-

trol input

- 0-10 V analogue input: 0 V = 0% speed;

+10 V = 100% speed

10 Chassis/Screen - Screen

11 +10 V analogue refer-

ence

– Control output

Posive +10 V analogue voltage reference output:

5 mA; unipolar output, diode protected.

12 Chassis/Screen - Screen

13 Not connected - Unused control pin

14 Remote – control input - Connect to pin 2 (0 V) to enable remote

control via parallel or serial control

modes.

15 Normal – status output - Logic low when the pump rotaonal

speed is at normal speed or above.

6.4 Parallel control and monitoring

CAUTION: EMF RISK

Risk of damag

e to equipment. If you use the normal and fail lines to drive the coils of

d.c. relays, include a back EMF suppression diode in parallel with each relay coil to

protect the pump.

Connect the control equipment to the control input pins of the logic interface mang

half

. Refer to Table: Logic interface pins to idenfy the logic interface connector pins. The

control inputs are:

▪ Start

▪ Standby speed

▪ Analogue speed

05/2021 - ©Edwards Limited

Page 31A90301880_C

A90301880_C - Oper

aon

Loading...

Loading...