ELIS PLZEŇ a. s., Luční 425/15, 301 00 Plzeň, Czech Republic, Phone: +420/377 517 711, Fax: +420/377 517 722 Es90420K/c

Make sure that the adjoining piping is clamped/supported as close to the sensor as possible, to prevent

vibrations and damage to the sensor.

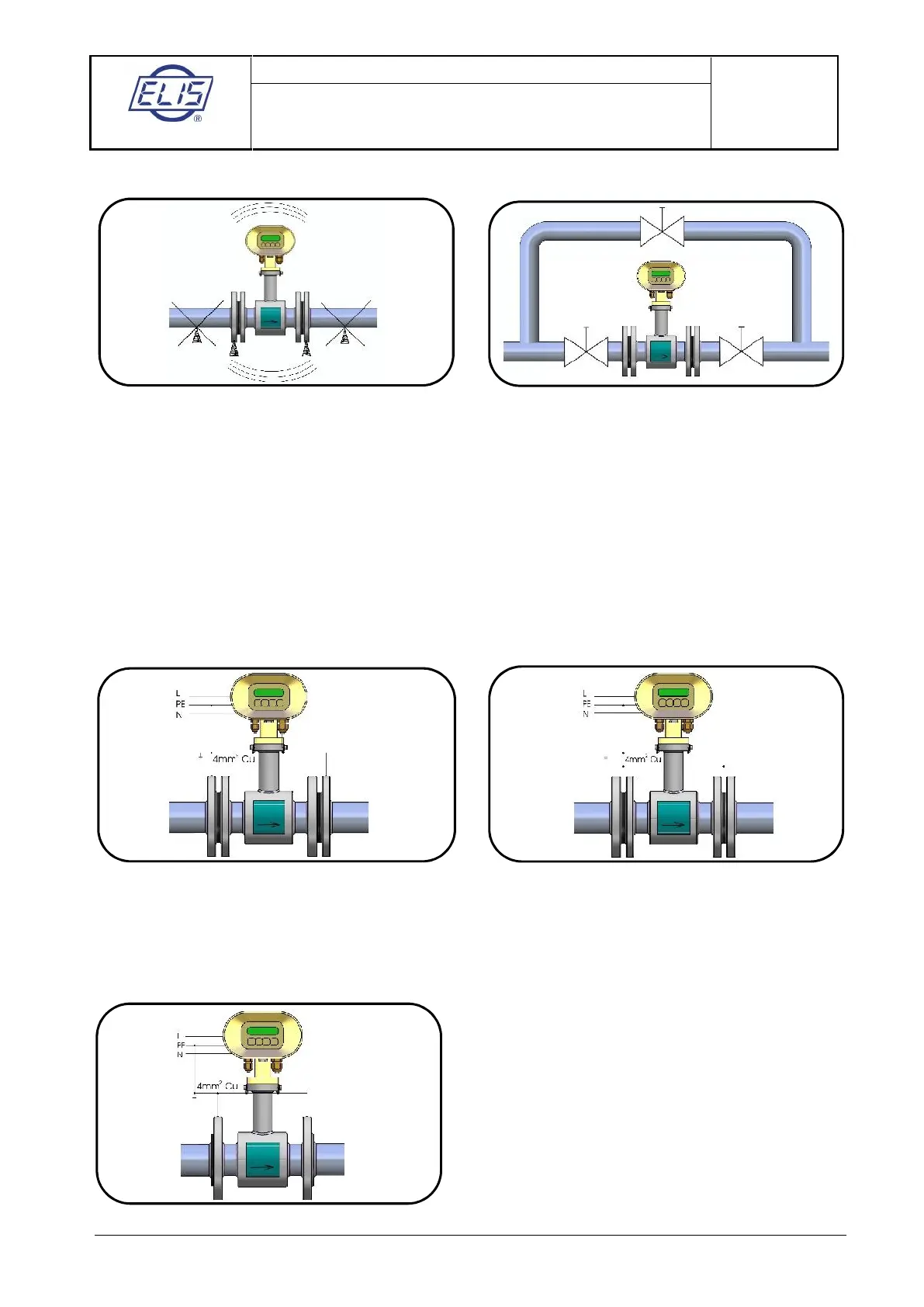

Undesirable sensor vibrations Sensor bypass

In applications where continuous liquid flow is essential, a bypass shall be provided to allow for sensor

servicing. A sensor bypass may also be a reasonable solution where dismantling the flow sensor would

require an emptying of a very long section of piping.

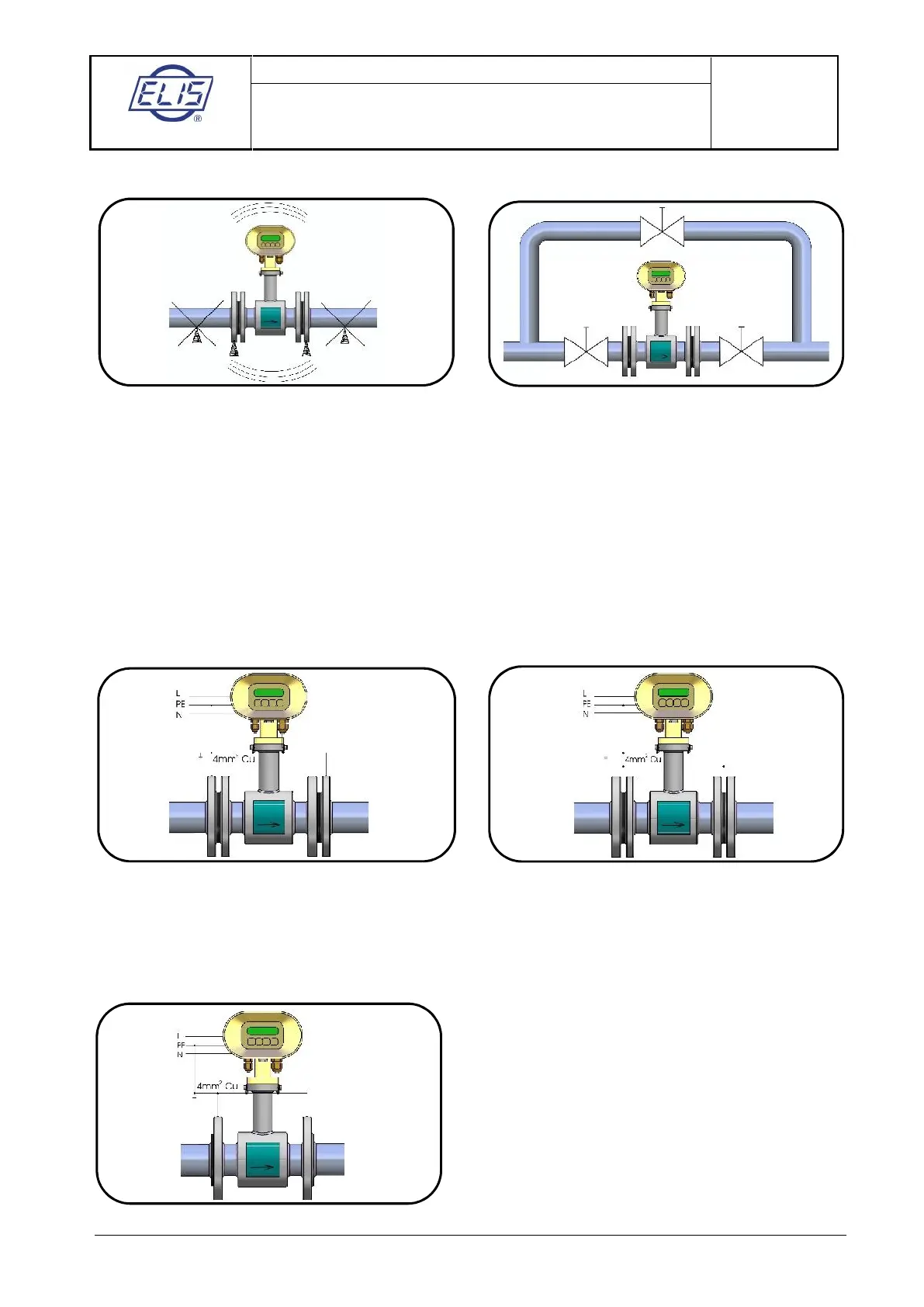

5.2. Sensor grounding

The correct meter function requires that both sensor and adjoining piping sections are duly interconnected to

the ground potential by low-impedance grounding conductors and a protective conductor from a power

supply. The overall arrangement shall be such that the potentials of the measured liquid at the sensor inlet

and outlet sides are close to the ground.

With a flanged sensor installed in electrically conductive piping, the flanges shall be electrically connected

with the piping and the piping connected to earth.

Flange grounding connection Grounding rings

Should the adjoining piping sections be non-conductive, grounding rings or similar instruments shall be used

to ensure that the electric potential of the measured liquid is properly grounded.

In case of a flangeless sensor, the piping flanges holding the sensor shall be electrically connected with the

grounding point on the sensor.

Flangeless sensor

To ensure potential equalisation for remote version of

flowmeter, it is recommended to interconnect the sensor

body with the transmitter housing with a copper

conductor of cross-section 4mm

2

.

Loading...

Loading...