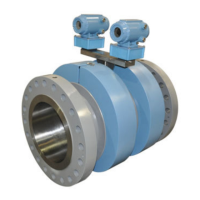

Figure 3-16: T-200 transducer stalk assembly configuration

3. Ensure that the setting of the transducer capsule assembly matches the stalk

assembly configuration (see Table 3-3). The setting of a transducer capsule

assembly is indicated by the number next to the slot where the tap is located (see

Figure 3-15), i.e. 1, 2, ... 8. The stalk assembly configuration is labeled on the

transducer stalk, next to its serial number (see Figure 3-16, i.e. -01, -02, ... -13 after

"T-200". If adjustment is needed:

a) Use one hand to hold the crystal holder and the other hand to hold the

transformer housing (see Figure 3-14).

b) Turn the transformer housing clock wise by 90 ° and slide it slowly to align

the tab to the proper position according to Table 3-3.

c) Turn the transformer housing counter-clock wise by 90 ° to let the tap snap

into the correct slot. Make sure the tap is secured in the slot.

4. Hold the transducer capsule assembly vertically and apply a small amount of

Acoustic Coupling Fluid (P/N: 1-360-01-650) to the surface of Kapton tape.

5. Carefully spread the coupling fluid on the surface of Kapton tape using the tip of the

plastic bottle for the coupling fluid.

Note

Do not press the Kapton tape while spreading the coupling fluid.

6. Wait for 30 - 60 seconds to let the coupling fluid spread more evenly on the surface.

7. Insert the transducer capsule assembly into the transducer stalk while aligning the

anti-rotation pin on the capsule with the slot on the inner surface of the stalk.

Maintenance and Troubleshooting manual Meter repairs

P/N 3-9000-769 June 2019

Maintenance and Troubleshooting manual 77

Loading...

Loading...