Prosonic Flow 92 10 Technical data

Endress+Hauser 55

10 Technical data

10.1 Brief technical data guide

10.1.1 Application

• Measuring the flow rate of fluids in closed piping systems.

• Applications in measuring, control and regulation technology for temporary process

surveying.

10.1.2 Function and system design

Measuring principle Prosonic Flow 92 operates on the principle of transit time difference.

Measuring system The flow measuring system consists of a transmitter and sensors.

Transmitter:

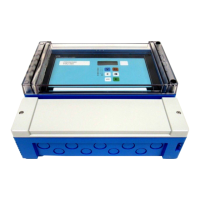

• Prosonic Flow 92

Flow measuring sensors:

• Prosonic Flow W

for nominal diameters DN 50...4000

• Prosonic Flow U

for nominal diameters DN 15...100

• Prosonic Flow P

for nominal diameters DN 50...300

10.1.3 Input

Measured variable Flow velocity (transit time difference proportional to flow velocity)

Measuring range Prosonic Flow W, P, U sensors typically v = 0...7 m/s with the specified measuring accu-

racy

Operable flow range Over 70 : 1

Input signal Current input: 4...20 mA, galvanically not isolated

10.1.4 Output

Output signal Current output:

Active 4...20 mA, R

L

= 0...1 kW, galvanically isolated (from ground and analog input)

Signal on alarm Current output

→ failsafe mode selectable

Load See “Output signal”

Low flow cut-off Switch point for low flow cut-off is selectable.

Galvanic isolation All circuits for outputs and power supply are galvanically isolated from each other.

Loading...

Loading...