14

Enertech Global IOM, XT Models

Water Quality

The quality of the water used in geothermal

systems is very important. In closed loop systems the

dilution water (water mixed with antifreeze) must

be of high quality to ensure adequate corrosion

protection. Water of poor quality contains ions that

make the uid “hard” and corrosive. Calcium and

magnesium hardness ions build up as scale on the

walls of the system and reduce heat transfer. These

ions may also react with the corrosion inhibitors

in glycol based heat transfer uids, causing them

to precipitate out of solution and rendering the

inhibitors ineffective in protecting against corrosion.

In addition, high concentrations of corrosive ions,

such as chloride and sulfate, will eat through any

protective layer that the corrosion inhibitors form on

the walls of the system.

Ideally, de-ionized water should be used for dilution

with antifreeze solutions since de-ionizing removes

both corrosive and hardness ions. Distilled water

and zeolite softened water are also acceptable.

Softened water, although free of hardness ions, may

actually have increased concentrations of corrosive

ions and, therefore, its quality must be monitored.

It is recommended that dilution water contain less

than 100 PPM calcium carbonate or less than 25

PPM calcium plus magnesium ions; and less than 25

PPM chloride or sulfate ions.

In an open loop system the water quality is of no

less importance. Due to the inherent variation of the

supply water, it should be tested prior to making the

decision to use an open loop system. Scaling of the

heat exchanger and corrosion of the internal parts

are two of the potential problems. The Department

of Natural Resources or your local municipality can

direct you to the proper testing agency. Please see

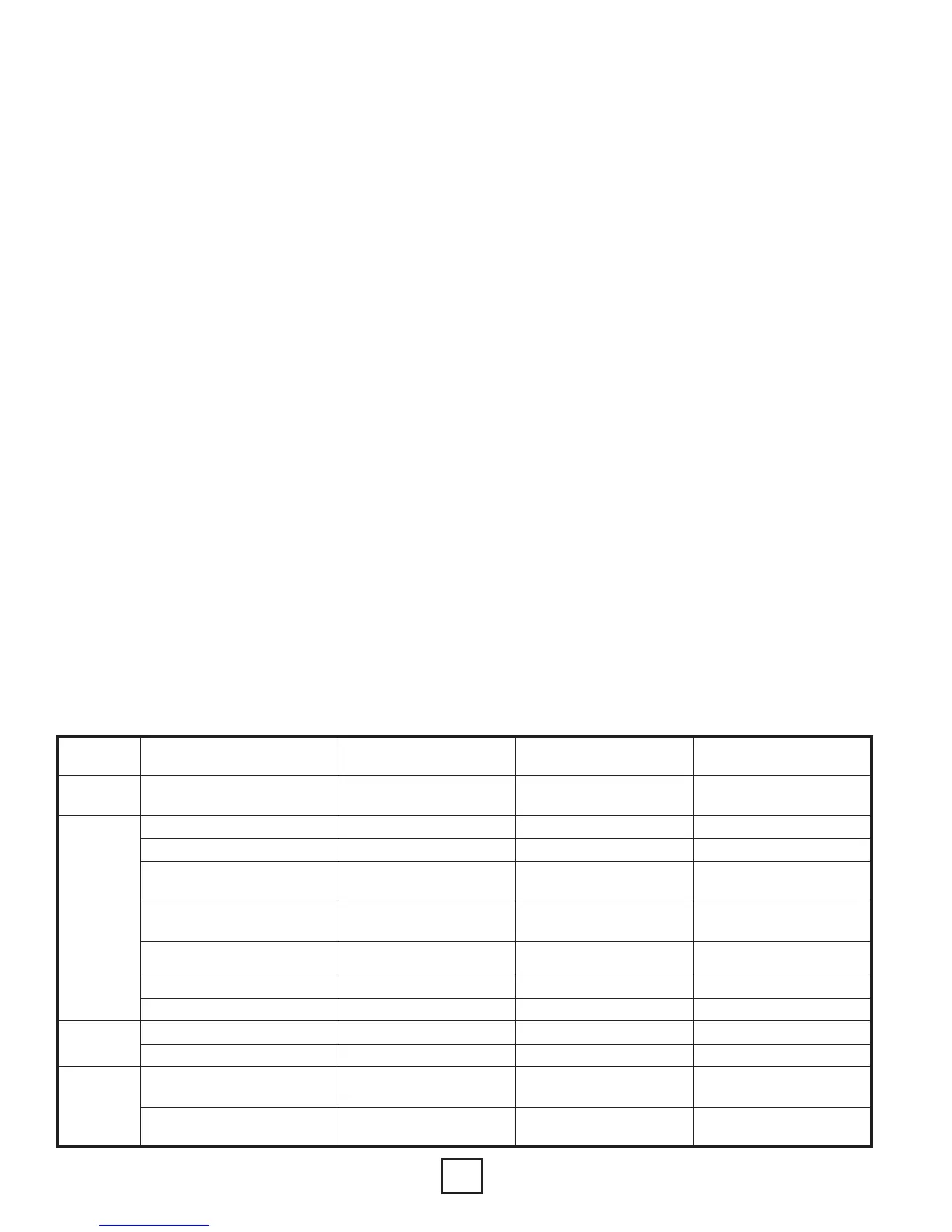

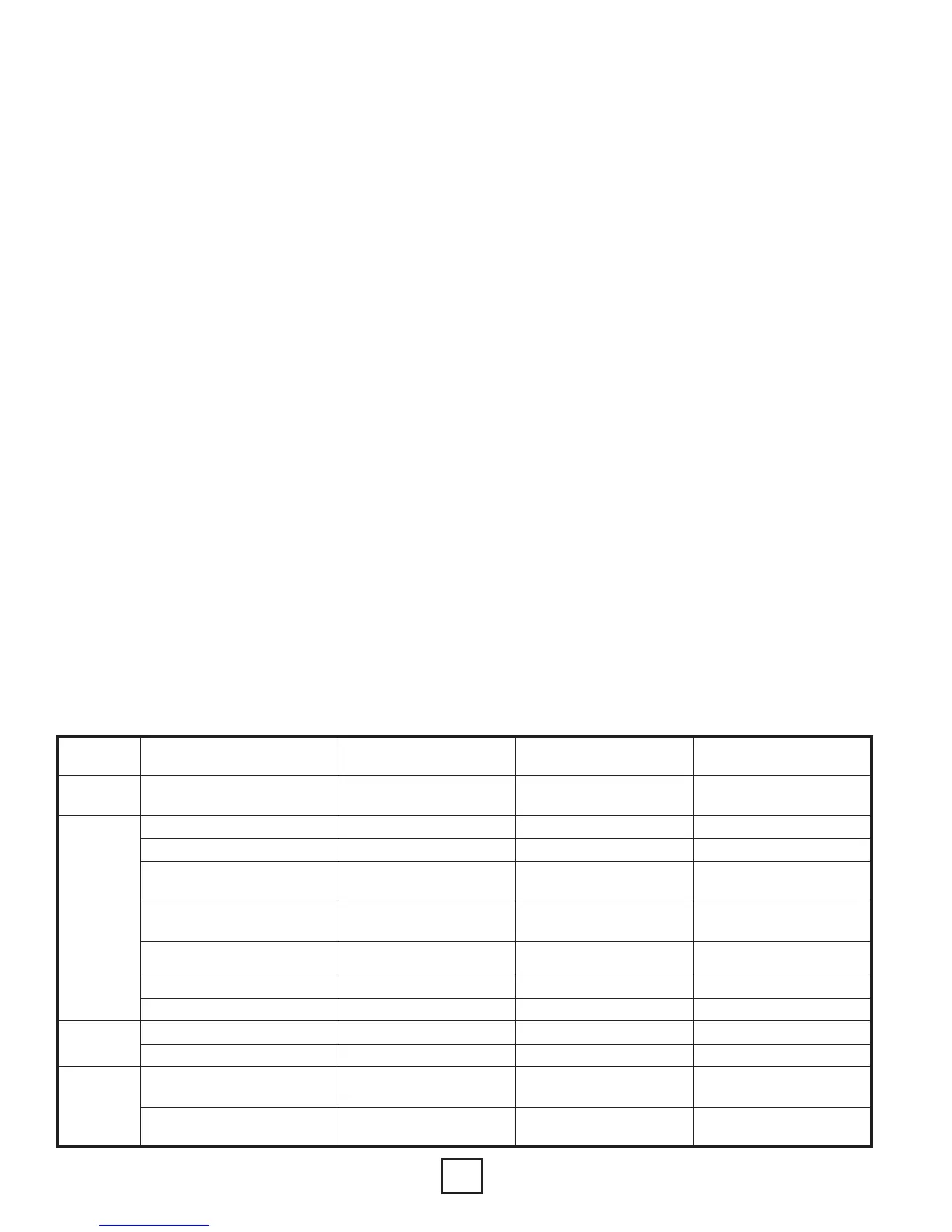

following table for guidelines.

Removing Debris During Purging

Most ow center or pump failures are a result of

poor water quality or debris. Debris entering the loop

during fusion and installation can cause noise aand

premature pump failure. Enertech recommends a

double ush ltering method during purging. When

purging, use a 100 micron bag lter until air bubbles

are removed. Remove the 100 micron bag, replace

it with a 1 micron bag and restart the ushing.

Water Quality Guidelines

Section 5: Unit Piping Installation

Potential

Problem

Chemical(s) or Condition

Range for Copper

Heat Exchangers

Cupro-Nickel Heat

Exchanger Ranges

Stainless Steel Heat

Exchanger Ranges

Scaling

Calcium & Magnesium

Carbonate

Less than 350 ppm Less than 350 ppm Less than 0.1 ppm

Corrosion

pH Range 7 - 9 5 - 9 7 - 9

Total Dissolved Solids Less than 1000 ppm Less than 1500 ppm No rigid setpoint

Ammonia, Ammonium

Hydroxide

Less than 0.5 ppm Less than 0.5 ppm No Limit

Ammonium Chloride,

Ammonium Nitrate

Less than 0.5 ppm Less than 0.5 ppm Less than 2-20 ppm

Calcium/Sodium Chloride

See Note 4

Less than 125 ppm Less than 125 ppm None Allowed

Chlorine Less than 0.5 ppm Less than 0.5 ppm Less than 1 ppm*

Hydrogen Sulde None Allowed None Allowed Less than 0.05 ppm

Biological

Growth

Iron Bacteria None Allowed None Allowed None Allowed

Iron Oxide Less than 1 ppm Less than 1 ppm Less than 0.2 ppm

Erosion

Suspended Solids - Note 5 Less than 10 ppm Less than 10 ppm

16-20 mesh strainer

recommended

Water Velocity Less than 8 ft/s Less than 12 ft/s

Less than 5.5 m/s in the

port

Loading...

Loading...