26

Enertech Global IOM, XT Models

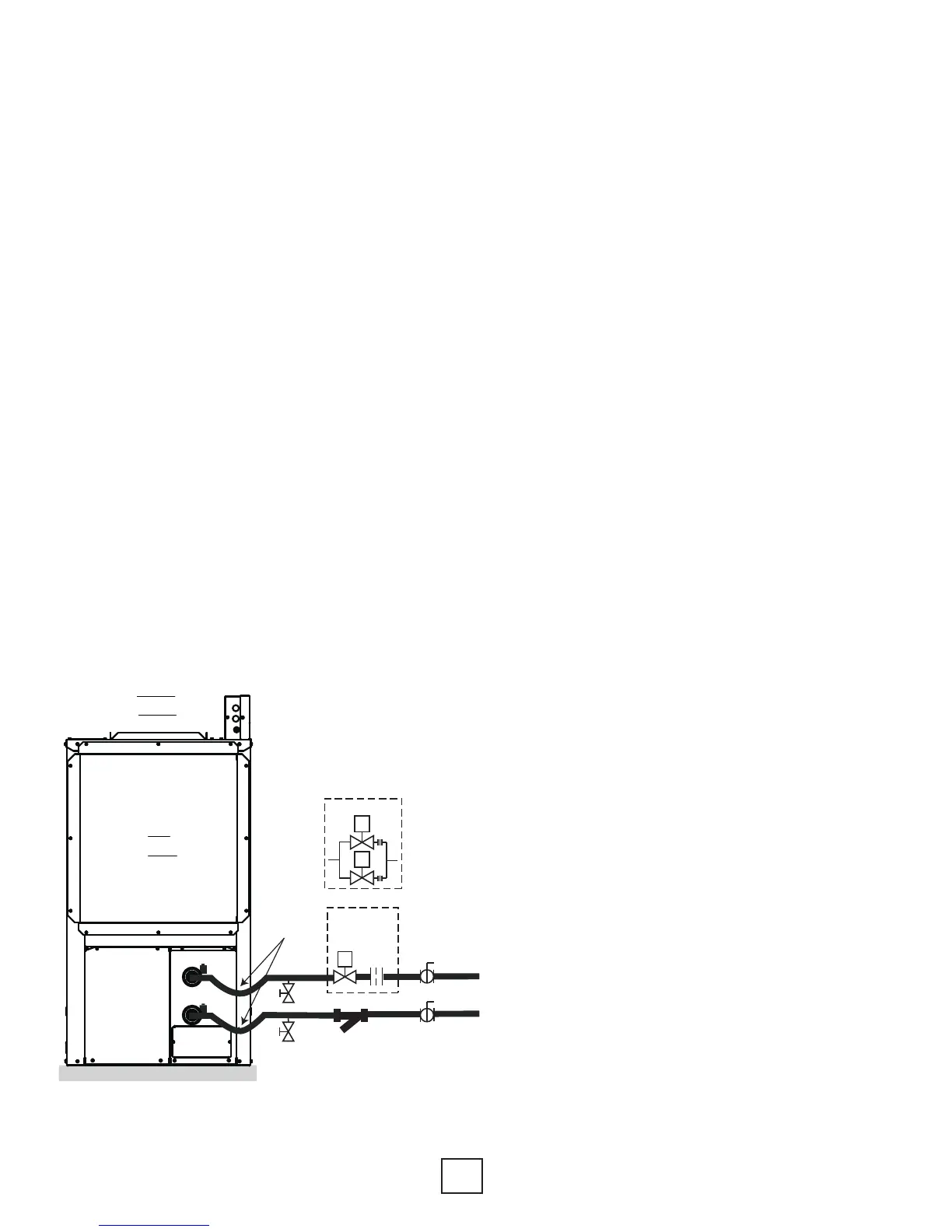

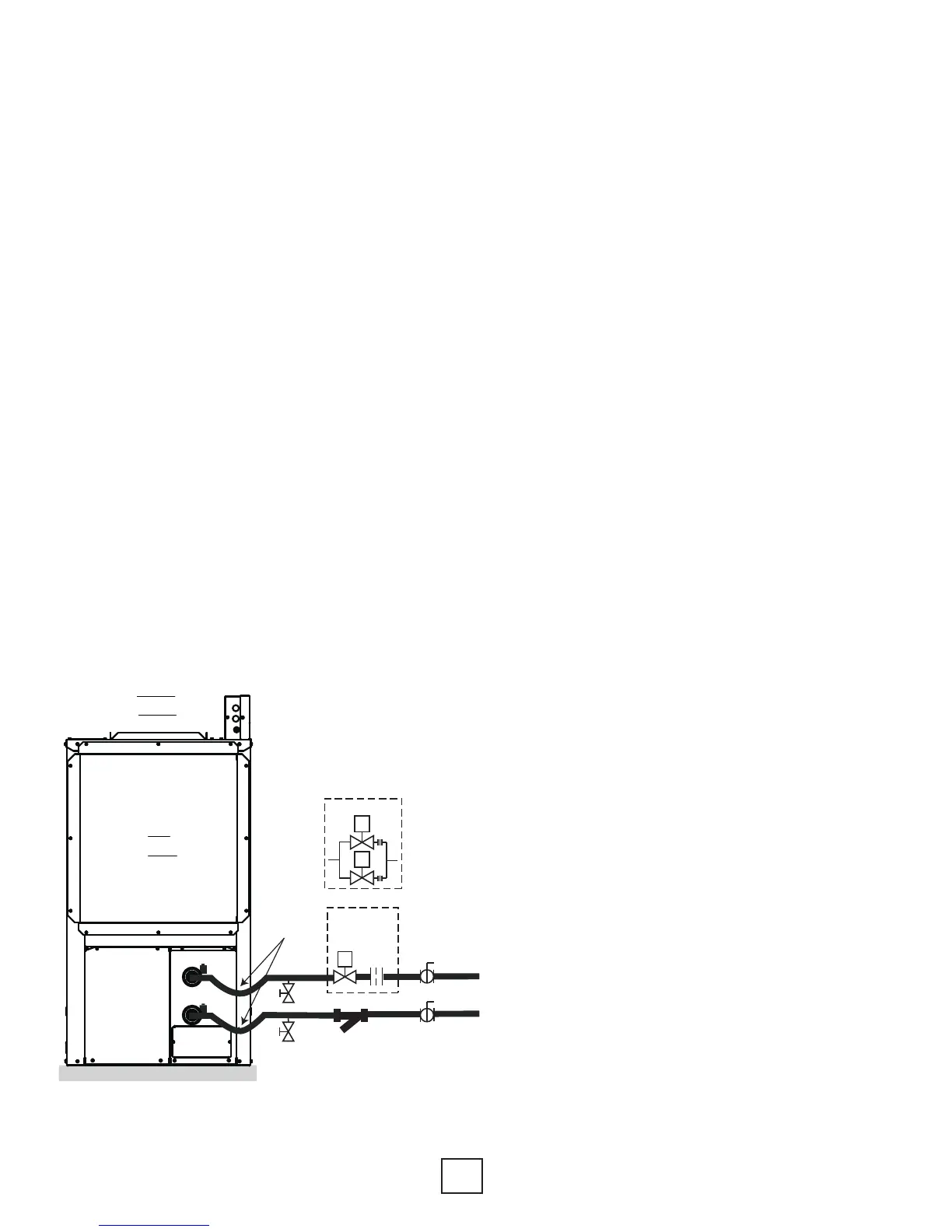

Open Loop Piping and Connections

Placement of the components for an open loop

system are important when considering water quality

and long term maintenance. The water solenoid

valve should always be placed on the outlet of the

heat pump, which will keep the heat exchanger

under pressure when the unit is not operating. If the

heat exchanger is under pressure, minerals will stay in

suspension. Water solenoid valves are also designed

to close against the pressure, not with the pressure.

Otherwise, they tend to be noisy when closing.

A ow regulator should be placed after the

water solenoid valve. Always check the product

specication catalog for proper ow rate. A

calculation must be made to determine the ow

rate, so that the leaving water temperature does not

have the possibility of freezing.

Other necessary components include a strainer,

boiler drains for heat exchanger ushing, P/T ports

and ball valves. Ball valves allow the water to be

shut off for service, and also help when velocity

noise is noticeable through the ow regulator.

Spreading some of the pressure drop across the ball

valves will lessen the

velocity noise. Always double check ow rate at the

P/T ports to make sure the ball valve adjustments

have not lowered water ow too much, and

essentially taken the ow regulator out of the

equation. It’s a good idea to remove the ball valve

handles once the system is completed to avoid

nuisance service calls.

Hose kits are optional, but make for an easier

installation, since the P/T ports and connections are

included. The hose also helps to isolate the heat

pump from the piping system.

Since the heat pump can operate at lower

waterow on rst stage, two stage units typically

include two water solenoid valves to save water.

The ow regulators should be sized so that when

one valve is open the unit operates at rst stage

ow rate, and when both valves are open, the unit

operates at full load ow rate. For example, a 4 ton

unit needs approximately 4 GPM on rst stage, and

approximately 7 GPM at full load. The ow regulator

after the rst valve should be 4 GPM, and the ow

regulator after the second valve should be 3 GPM.

When both valves are open, the unit will operate at

7 GPM.

The drawings show typical components, wiring and

connection points. Electrical connections are found

at the control box terminal strips.

Figure 5: Open Loop Piping Example

LEFT

VIEW

air

coil

Non-Pressurized

Flow Center

P/T Ports

Source Out

Source In

P/T Ports

*Hose

Kits

Equipment Pad

2” Polyethylene Foam

Boiler

Drains

(2 required)

S

Single Stage

Units

Ball Valve

(2 required)

S

S

Two Stage Units

Strainer

(optional)

OR

**Flow

Regulator

From

Loop

Field

To

Loop

Field

Flush

Valve

*Hose kit is used for piping isolation, and includes ttings for P/T ports.

**See product specifications for flow rates.

Note: All XT models are

two-stage units.

Two-Stage solenoid example

is optional for all sizes. It is not

recommended for 3 ton and

smaller. Use single solenoid

and ow regulator.

Section 5: Unit Piping Installation

Loading...

Loading...