39

IOM, XT Models Enertech Global

Lockout with Emergency Heat

While in lockout mode, if the thermostat is calling for

backup heat, emergency heat mode will occur.

Diagnostics

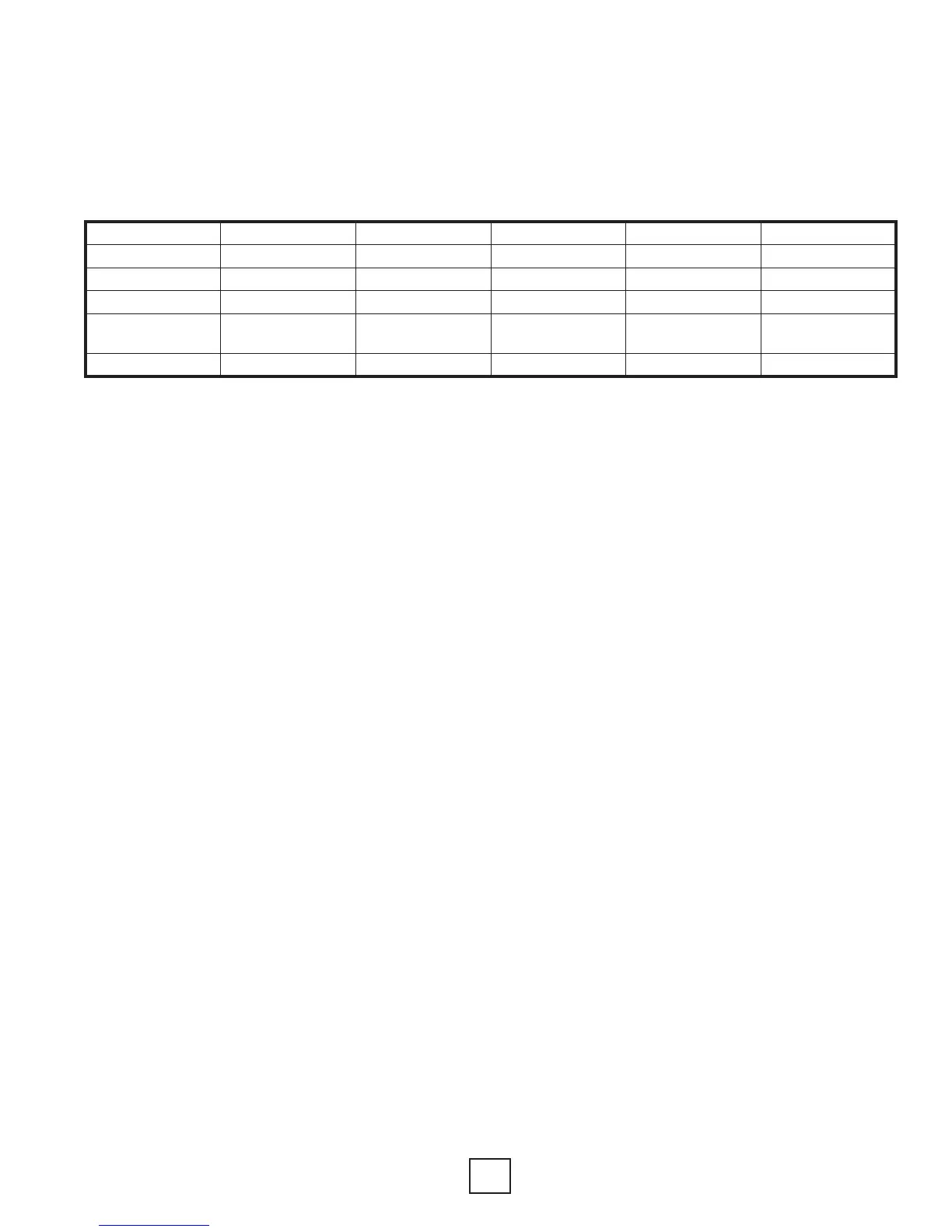

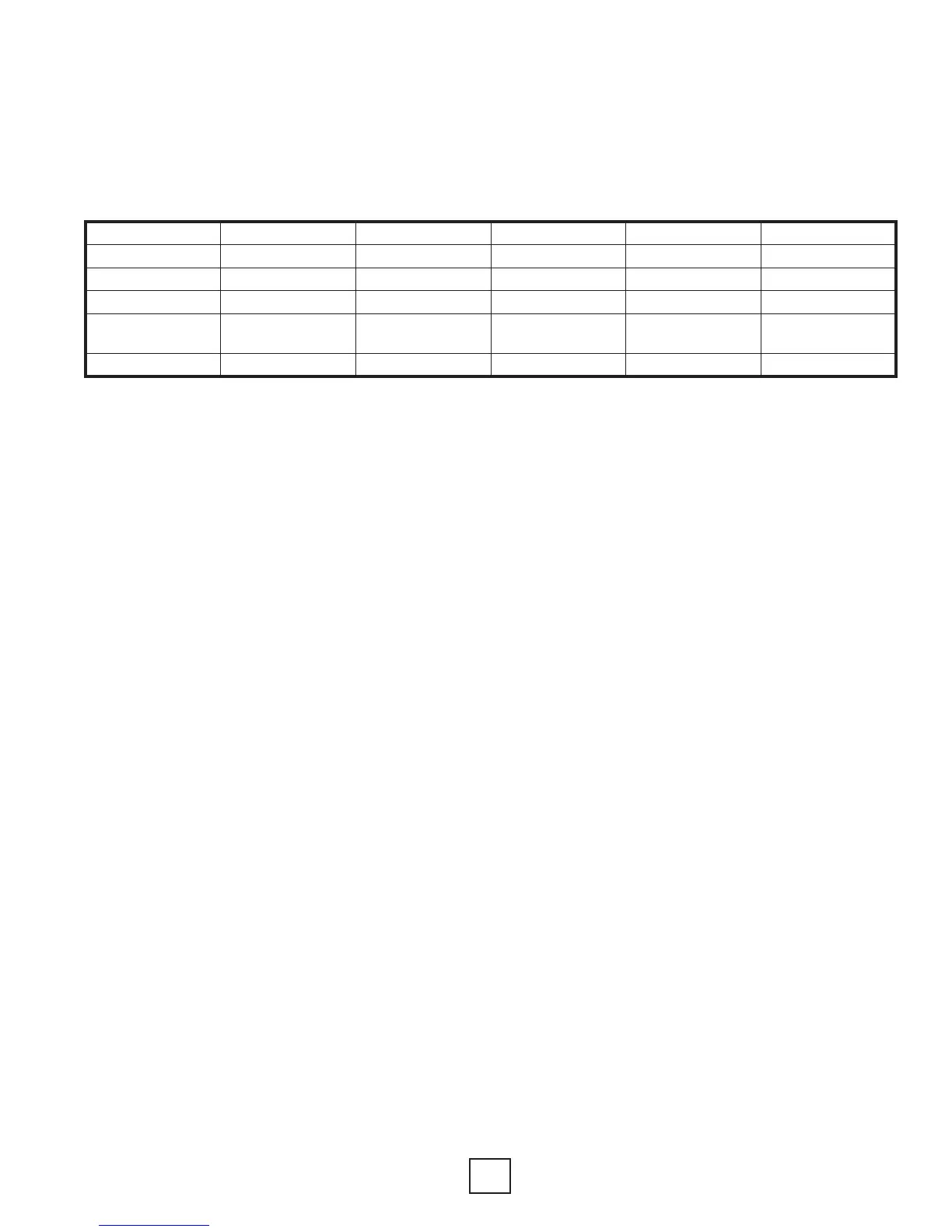

The lockout board includes ve LEDs (status, high

pressure, low pressure, low water ow, condensate

overow) for fast and simple control board

diagnosis. Below is a table showing LED function.

Section 9: Controls

LED Color Location

1

Function Normal Operation Fault Retry

2

Lockout

2

Green To p High Pressure OFF Flashing

3

ON

3

Orange 2nd Low Pressure OFF Flashing

3

ON

3

Red 3rd Water Flow OFF Flashing

3

ON

3

Yellow 4th

Condensate

Overow

OFF Flashing

3

ON

3

Green Bottom Status Flashing

4

Flashing

5

Flashing

4

Notes:

1. Looking at the board when the LEDs are on the right hand side.

2. If all ve lights are ashing, the fault is over/under voltage.

3. Only the light associated with the particular fault/lockout will be on or ashing.

For example, if a high pressure lockout has occurred, the top green light will be on.

The orange, red, and yellow lights will be off.

4. Status lights will be off when in test mode.

5. Flashes alternately with the fault LED.

Lockout Board LED Identication

Hot Water Pump Control

Controls for high water temperature and low

compressor discharge line temperature prevent the

hot water (desuperheater) pump from operating

when the leaving water temperature is above 130°F,

or when the compressor discharge line is too cool to

provide adequate water heating.

Lockout Board Jumper Selection

The lockout board includes three jumpers for eld

selection of various board features.

Water Solenoid Valve Delay (WSD): When the WSD

jumper is installed, the “A” terminal is energized 10

seconds before the compressor is energized. When

the jumper is removed, the “A” terminal is energized

with the compressor. If using a water solenoid valve

without an end switch, connect to terminal “A”. If

using a water solenoid valve with an end switch,

connect to terminals YT and YU(remove the jumper

wire).

Refer to wiring diagram. Enertech recommends the

use of a slow acting valve to reduce the chance of

water hammer.

Test Mode (TEST): When the TEST jumper is installed,

the board operates in the normal mode.

When the jumper is removed, the board operates

in test mode, which speeds up all delays for easier

troubleshooting. When service is complete, the

jumper must be re-installed in order to make sure

that the unit operates with normal sequencing

delays. While the test jumper is removed, the status

light (bottom green) will remain off.

Over/Under Voltage Disable (O/V): When the

O/V jumper is installed, the over/under voltage

feature is active. When the jumper is removed, the

over/under voltage feature is disabled. On rare

occasions, variations in voltage will be outside the

range of the over/under voltage feature, which may

require removal of the jumper. However, removal

of the jumper could cause the unit to run under

adverse conditions, and therefore should not be

removed without contacting technical services.

An over/under voltage condition could cause

premature component failure or damage to the

unit controls. Any condition that would cause this

fault must be thoroughly investigated before taking

any action regarding the jumper removal. Likely

causes of an over/under voltage condition include

power company transformer selection, insufcient

entrance wire sizing, defective breaker panel,

incorrect transformer tap (unit control box), or other

power-related issues.

Loading...

Loading...