8

Enertech Global IOM, XT Models

Unit Placement

When installing a geothermal heating and cooling

unit, there are several items the installer should

consider before placing

the equipment.

1. Service Access. Is there enough space for

service access? A general rule of thumb is at

least 2 feet in the front and 2 feet on at least one

side.

2. Unit Air Pad. All vertical geothermal heating

and cooling equipment should be placed on

either a formed plastic air pad, or a high density,

closed cell polystyrene pad. Downow units

should be placed on a non-combustible base.

This helps eliminate vibration noise that could be

transmitted through the oor.

3. The installer has veried that all applicable

wiring, ductwork, piping, and accessories are

correct and on the job site.

Section 3: Installation Considerations

Duct Work

All new ductwork shall be designed as outlined

in Sheet Metal and Air Conditioning Contractors

National Association (SMACNA) or Air Conditioning

Contractors of America (ACCA) or American

Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) handbooks.

All supply/return plenums should be isolated

from the unit by a exible connector (canvas) or

equivalent to prevent transfer of vibration noise

to the ductwork. The ex connector should be

designed so as not to restrict airow. Turning vanes

should be used on any transition with airow over

500 CFM. If the unit is installed in a unconditioned

space, the metal ductwork should be insulated

on the inside with berglass insulation or similar

insulation to prevent heat loss/gain and to absorb

air noise. If the unit is being installed with existing

ductwork, the ductwork must be designed to

handle the air volume required by the unit being

installed. When running a cooling or heating load on

a building, size ductwork accordingly to the building

design load and heat pump CFM.

Industry Standard: When sizing ductwork use 400

CFM per Ton.

As a general rule, maximum recommended face

velocity for a supply outlet used in a residential

application is 750 FPM. Maximum recommended

return grille velocity is 600 FPM. Systems with higher

velocity, are likely to have noise problems.

In buildings where ceilings are 8 feet or more, at

least 50 percent of the return air should be taken

back to the heat pump from the ceiling or high

sidewall location and not more than 50 percent

from the oor or low sidewall location.

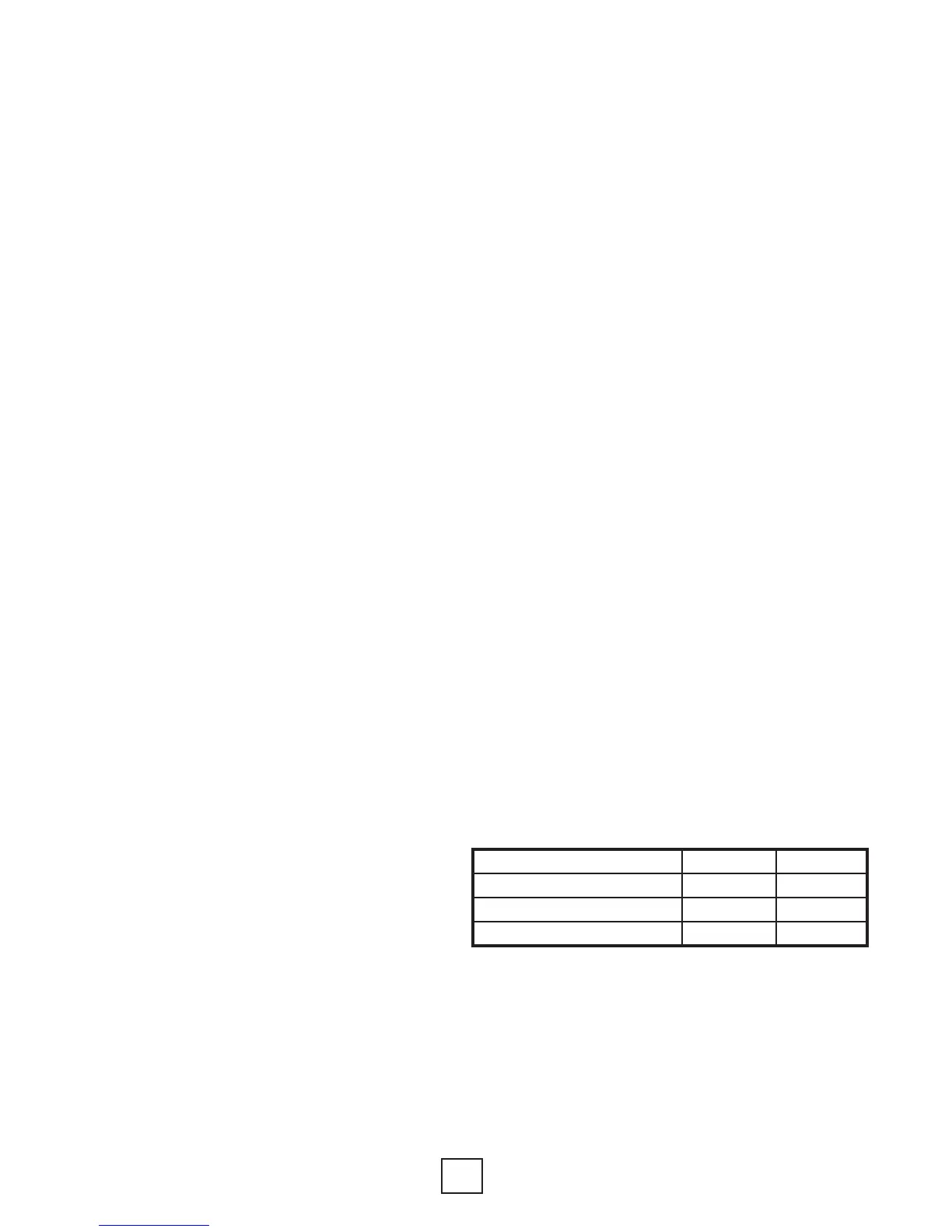

Table 1: Maximum Air Velocities

Location Supply Return

Main Ducts 900 FPM 600 FPM

Branch Ducts 700 FPM 600 FPM

Grills, Registers, Diffusers 750 FPM 600 FPM

Loading...

Loading...