20

Enertech Global IOM, XT Models

3. Turn the pump back on. It may be necessary to

turn the water supply back on to keep the water

level in the reservoir above the return tee.

4. This should only take 5 to 10 minutes to purge the

unit.

5. Once this is done, the entire system is now full of

water, and the ush cart pump may be turned

off.

Step 3: Adding Antifreeze by Displacement

If the antifreeze was not added when the loop was

being lled, it will be necessary to follow the next

few steps.

1. Turn both 3-way “Ts” back to the original position

for ushing the loop only.

2. Close the return side ball valve on the ush cart.

3. Connect hose to the return side discharge line

and run it to a drain. Open the ball valve on

discharge line on ush cart.

4. Turn pump on until water level is sucked down

just above the water outlet in the reservoir, and

turn pump off. Be sure not to suck air back into

the system.

5. Fill the reservoir back up with the antifreeze.

6. Repeat steps 5 and 6 until all the antifreeze is in

the system and reservoir.

7. Turn the discharge line ball valve off at the ush

cart. Turn the return line ball valve back to the

on position.

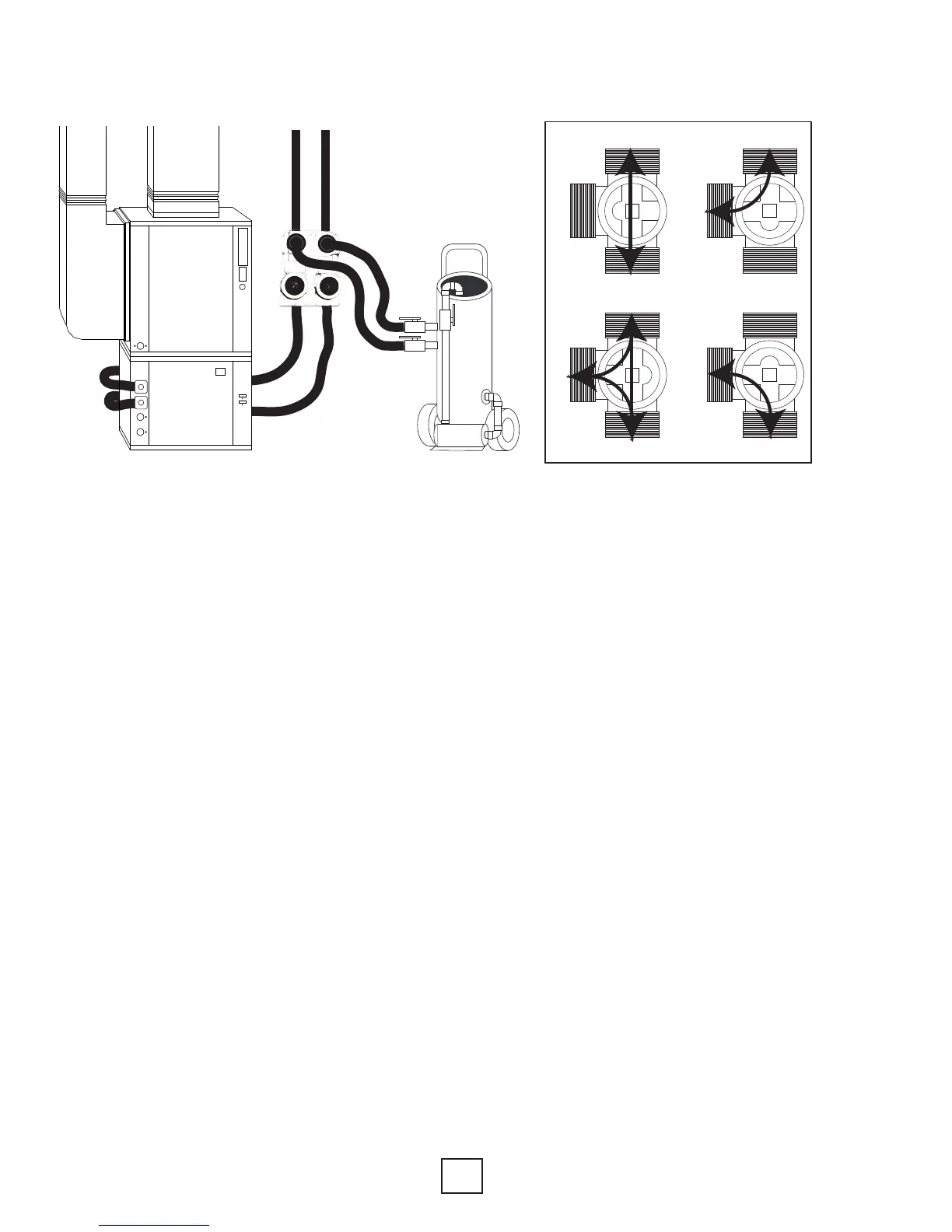

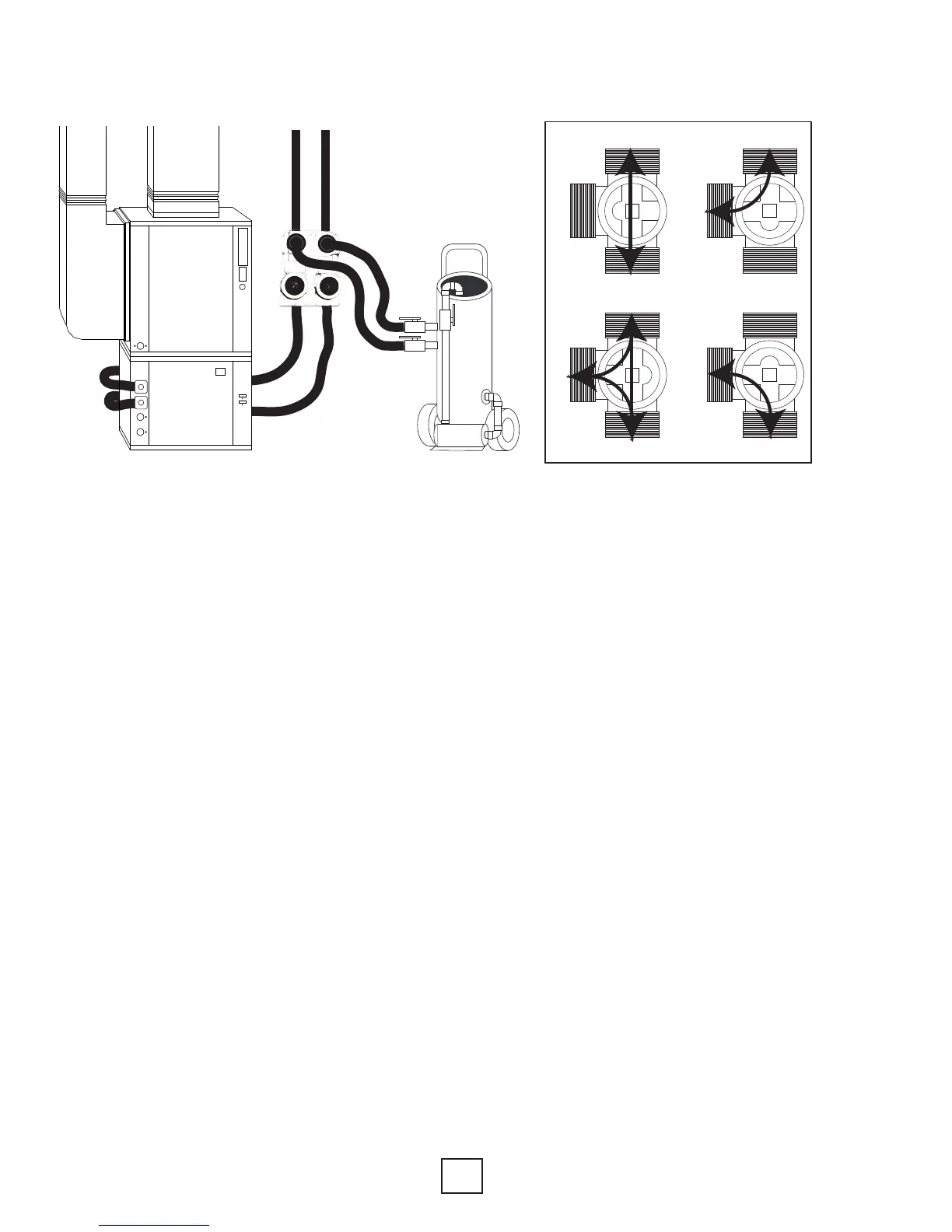

Figure 7: Flush Cart Connections Figure 8: Flow Center 3-Way Valves

Flush Port

Loop Loop

Loop Loop

Unit Unit

Unit Unit

Section 5: Unit Piping Installation

1. Once the water level stays above the “T” in

the reservoir, turn off the water supply (this also

allows observation of air bubbles).

2. 8.

Run the pump for a minimum of 2 hours for

proper ushing and purging (depending on

system size it may take longer).

3. “Dead head” the pump every so often and

watch the water level in the reservoir. Once all

the air is removed there should not be more than

a 1” to 2” drop in water level in the reservoir. If

there is more than a 2” drop, air is still trapped in

the system. This is the only way to tell if air is still

trapped in the system.

4. To dead head the pump, shut off the return side

ball valve on the ush cart. This will provide a

surge in pressure to the system piping, helping to

get the air bubbles moving. Do not reverse ow

during ushing.

Water Quality: Even on a closed loop system water

quality is an issue. The system needs to be lled with

clean water. If the water on site has high iron content,

high hardness, or the PH is out of balance, premature

pump failure may result. Depending upon water

quality, it may need to be brought in from off site.

Step 2: Flushing the Unit

1. Turn off the pump on the ush cart.

2. Turn both 3-way valves to the unit and ush port

position.

Loading...

Loading...