Maintenance 8. Arm #4

G3 Rev.14 139

Loosely secure the Joint #4

Make sure the motor unit can be moved

by hand, and it will not tilt when pulled.

If the unit is secured too loose or too

tight, the belt will not have the proper

tension.

Joint #4

intermediate shaft

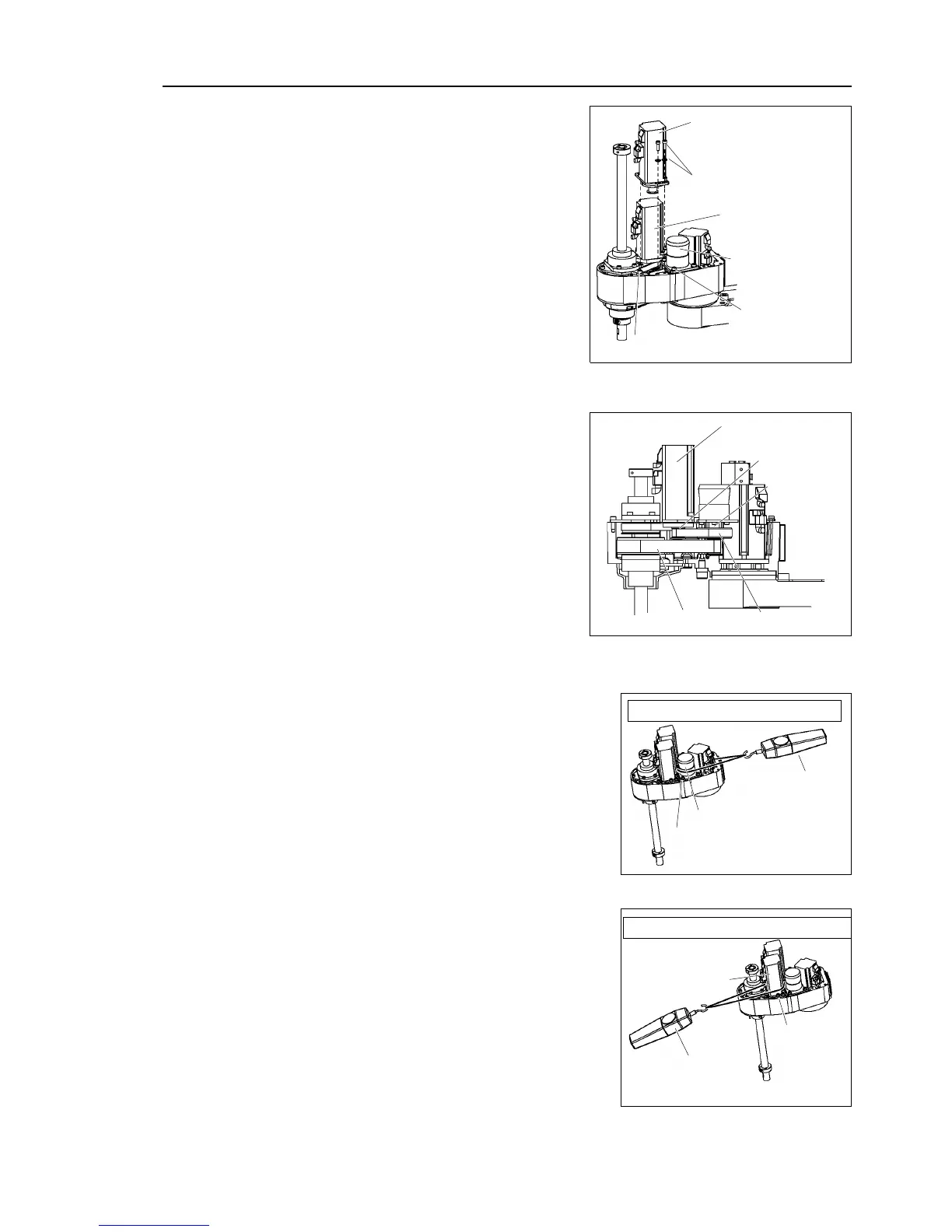

Joint#4 motor unit around the

U1 belt. Put the Joint #4 motor unit on

the Arm #2 top surface.

Put the Joint #4 motor cable toward the

end of Arm #2.

Loosely secure the Joint #4 motor unit to

Arm #2.

the motor unit can be moved

hand, and it will not tilt when pulled.

f the unit is secured too loose or too

, the belt will not have the proper

Loosely secure the spline plate to Arm #2.

After moving the shaft up and down

several times, secure the spline plate to Arm #2.

Apply the proper tension to the U2 belt, and

then secure the Joint #4 intermediate shaft

unit.

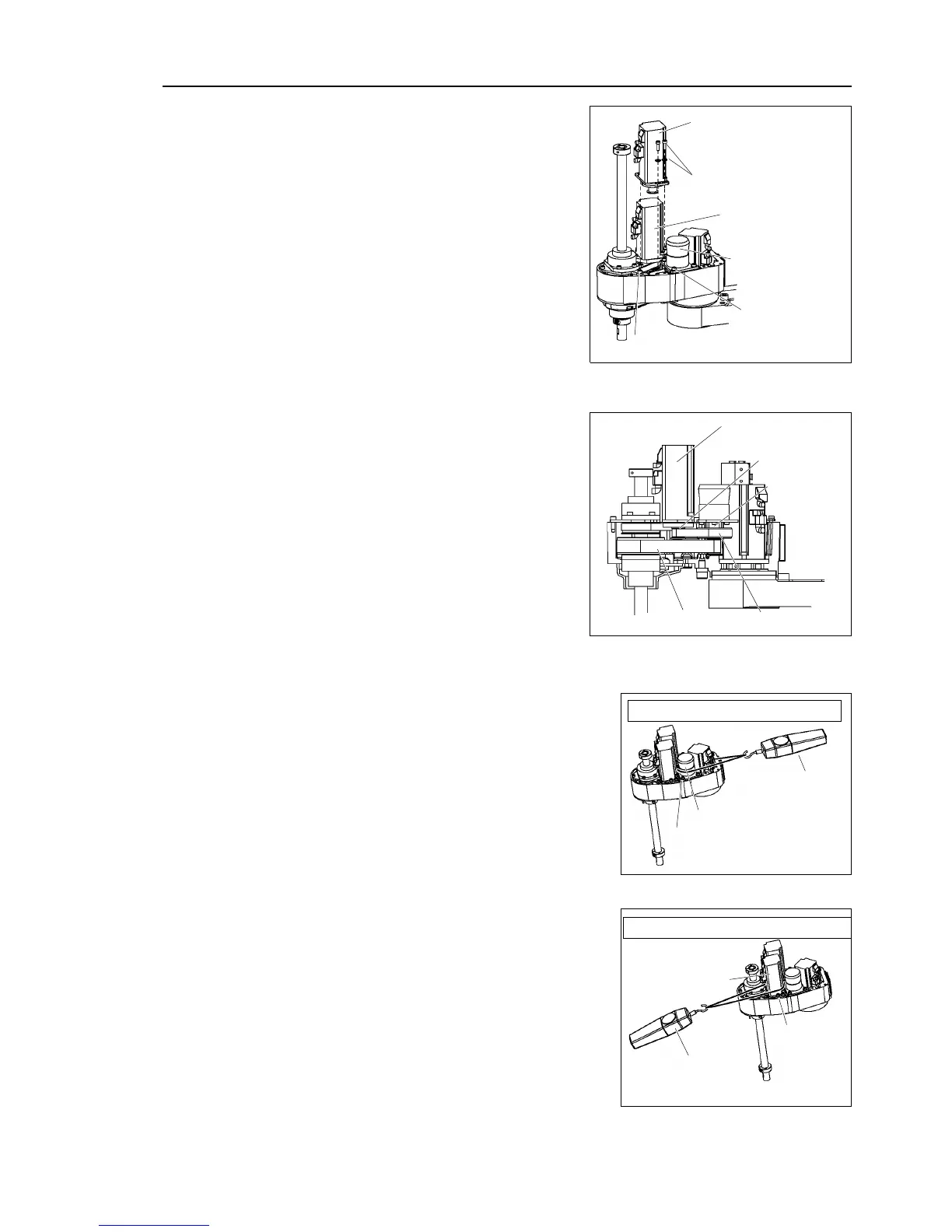

ass a suitable cord or string around

4 intermediate shaft unit near its

Then, pull the cord using a

force gauge or similar tool to apply the

specified tension shown in the figure on

U2 belt tension

= 98 N (10 ± 1 kgf

)

Joint #4 intermediate shaft

Apply the proper tension to the U1 belt, and

then secure the Joint #4 motor unit.

ass a suitable cord or string around the Joint

4 motor unit near its mounting plate.

Then, pull the cord using

similar tool to apply the

U1 belt tension = 74 N (7.5 ± 0.5 kgf)

Loading...

Loading...