Maintenance 6. Arm #2

LS Rev.10 101

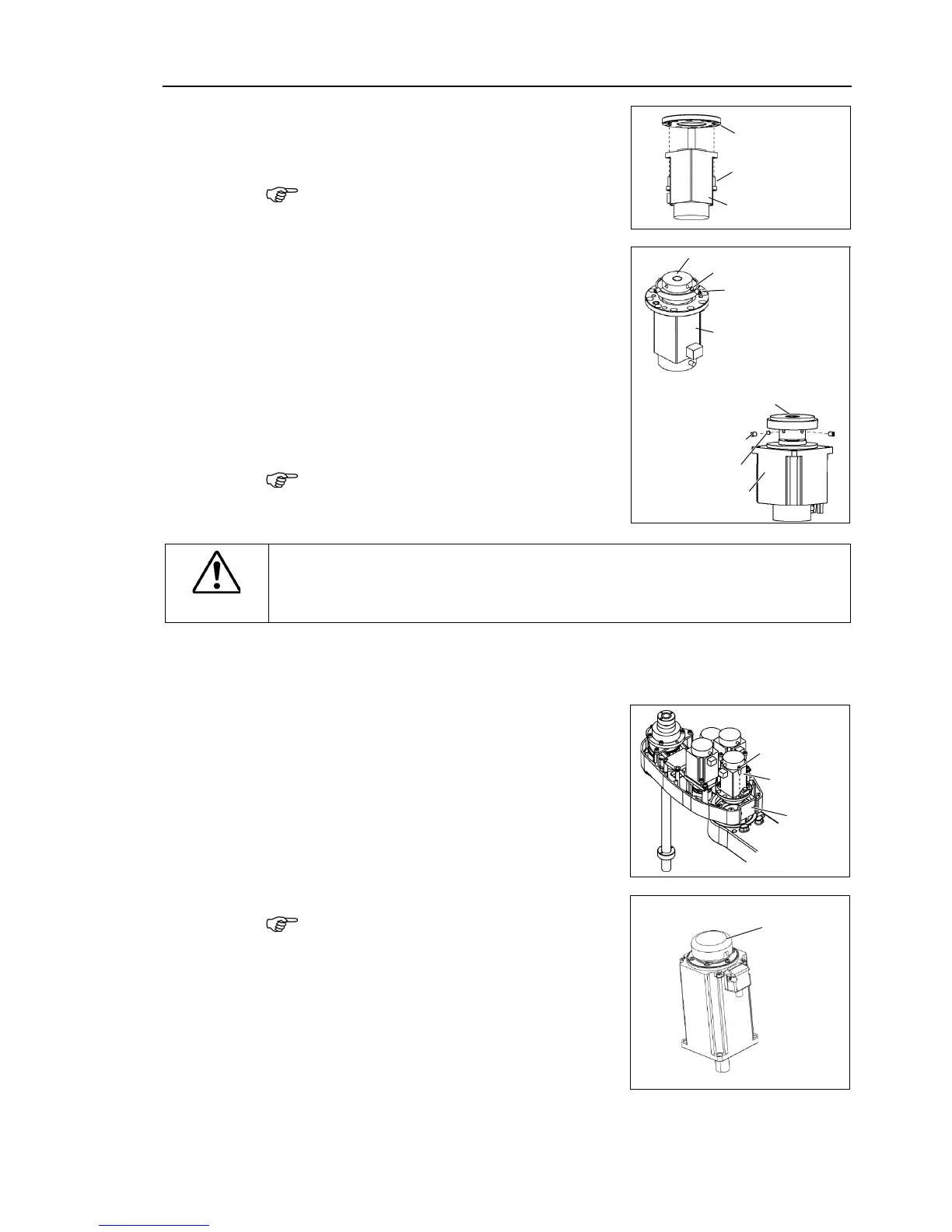

Mount the motor flange on the Joint #2

LS6 does not have a motor flange.

Mount the waveform generator on the Joint

align the end face of the waveform

generator to the end face of the motor

flat face of the motor shaft.

et screw hole to prevent damage

Fix the waveform generator at the

position where the end face is 0.5 mm

from the end face of the motor shaft.

the figures above for the orientation of the waveform generator. Be sure to

install the waveform generator properly.

Improper installation of the waveform

generator will result in improper function of the Manipulator.

Apply grease between the waveform generator and motor flange.

Grease volume LS3: 4 g (SK-2)

LS6: 6 g (SK-1A)

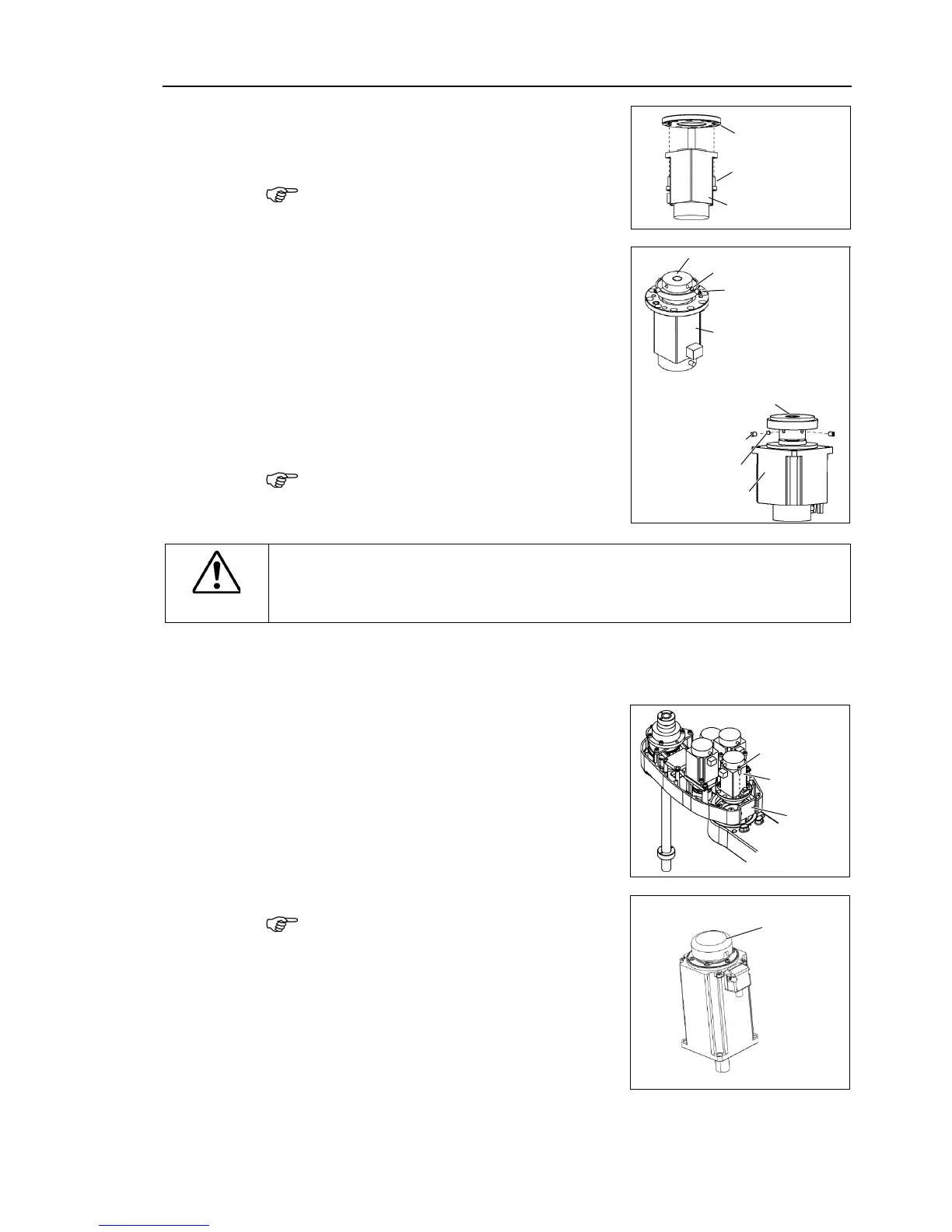

ount the Joint #2 motor unit on the Arm #2.

To insert the motor, slowly move the Arm #2 by

hand and push in.

LS3: Motor flange mounting screw 3-M4×10

LS6: Motor mounting screw 4-M4×12

When replacing the motor of the Joint # 2, 3,

and 4, remove the cap from the old motor and

install it to the new one.

If the Manipulator is operated while the cap is

not installed, the motor may be

entering of the foreign materials into the

rotating part of

motor sensor and

interference of the rotating part and the cables.

Loading...

Loading...