VT6L Maintenance 10. Joint #2

VT series Maintenance Manual Rev.2 79

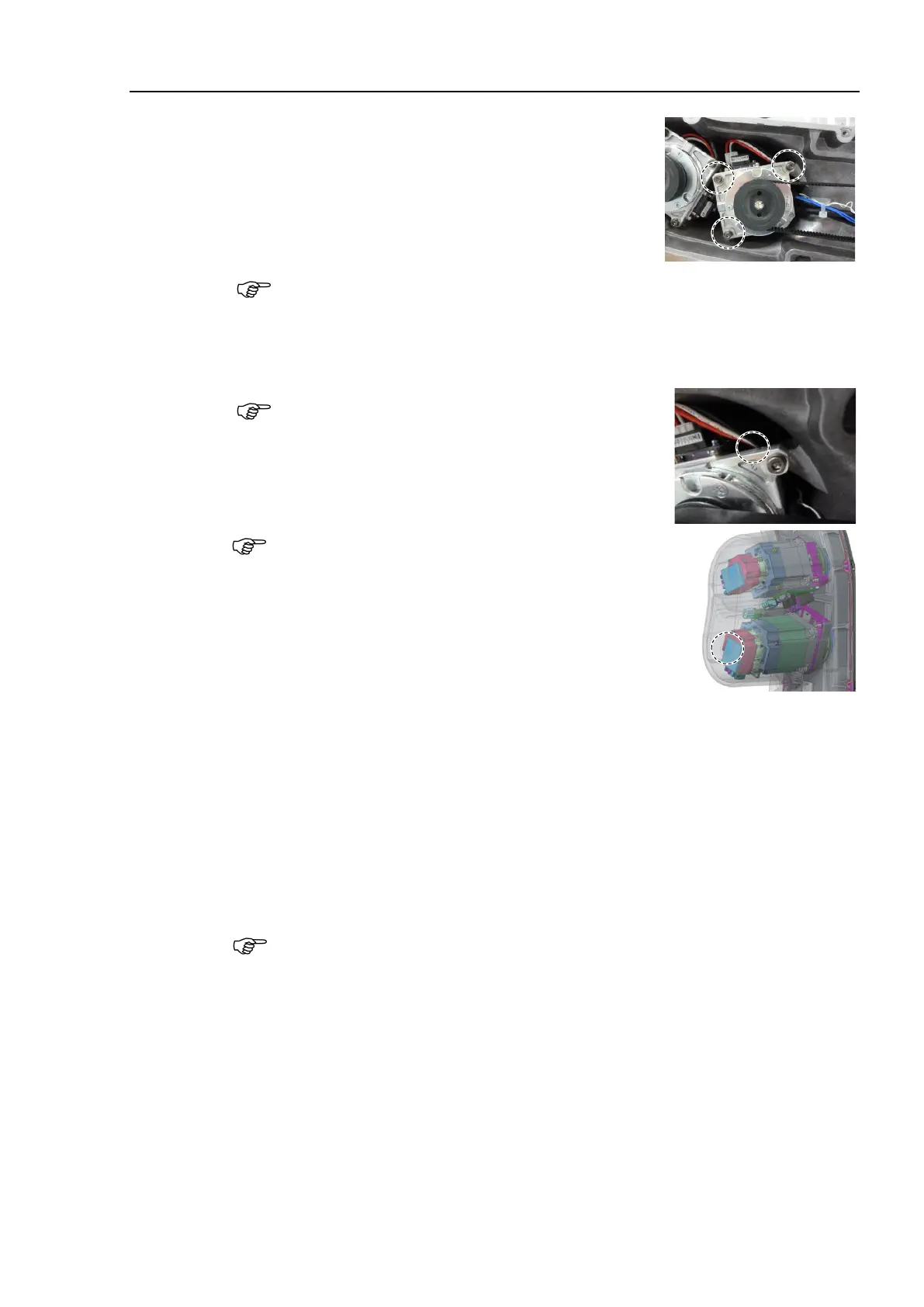

Pass the timing belt through the motor pulley and

to the Arm #2.

Hexagon socket head cap bolts: 3-M4×22

(with slotted hole washer)

Make sure that the gear grooves of the timing belt are fit

into those of the pulley

When securing the motor unit loosely, make sure that the motor unit can be moved

by hand and it does not tilt when being pulled. If the unit is secured too loose or

too tight, the belt will not have proper tension.

As shown on the picture, pass the cable through the

rear side of the Arm #2 motor unit fixing part.

Before fixing the motor unit, make sure that the cables

are not caught in the gap between the motor unit and

Arm #2.

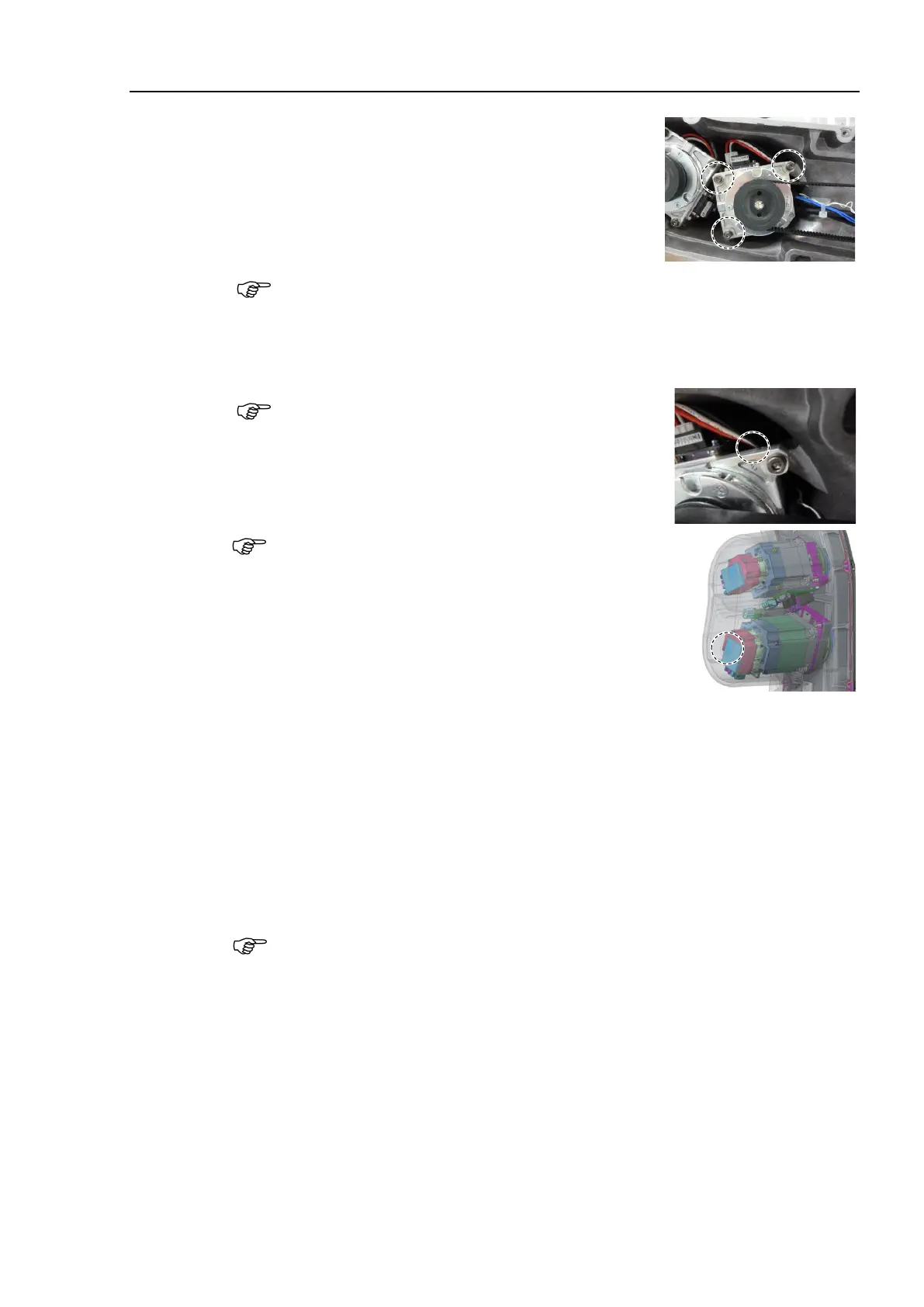

thermal conductive sheet on the rear side of

the motor unit to the round convex part at the end of

the Arm #2.

Apply proper tension to the motor unit and fix it.

Joint #2 timing belt tension: 34 - 58 N

Belt tension meter setting values

Weight: 2.5g/mm width×m span

Width: 9.0mm

Span: 172mm

Hexagon socket head cap bolts: 3-M4×22 (with slotted hole washer)

Tightening torque: 4.0 ± 0.2 N·m

ay occur if the value is below the lower limit.

Vibration (abnormal noise) or reduction in life of the parts may occur if the value

exceeds the upper limit.

When you replace with a new belt, belt extends and the belt tension may decrease in

the initial sta

ge. Make sure to operate the robot two to three days and check the belt

Loading...

Loading...