5 OPERATION

0463 479 001

- 22 -

© ESAB AB 2017

NOTE!

Make sure the correct feed/pressure rollers are used. For more information see

appendix WEAR PARTS.

NOTE!

Remember to use the correct contact tip in the welding torch for the wire diameter

used. The torch is fitted with a contact tip for 0.030in. (0.8 mm) wire. If you use

another diameter you must change the contact tip and drive roll. The wire liner

fitted in the torch is recommended for welding with Fe and SS wires.

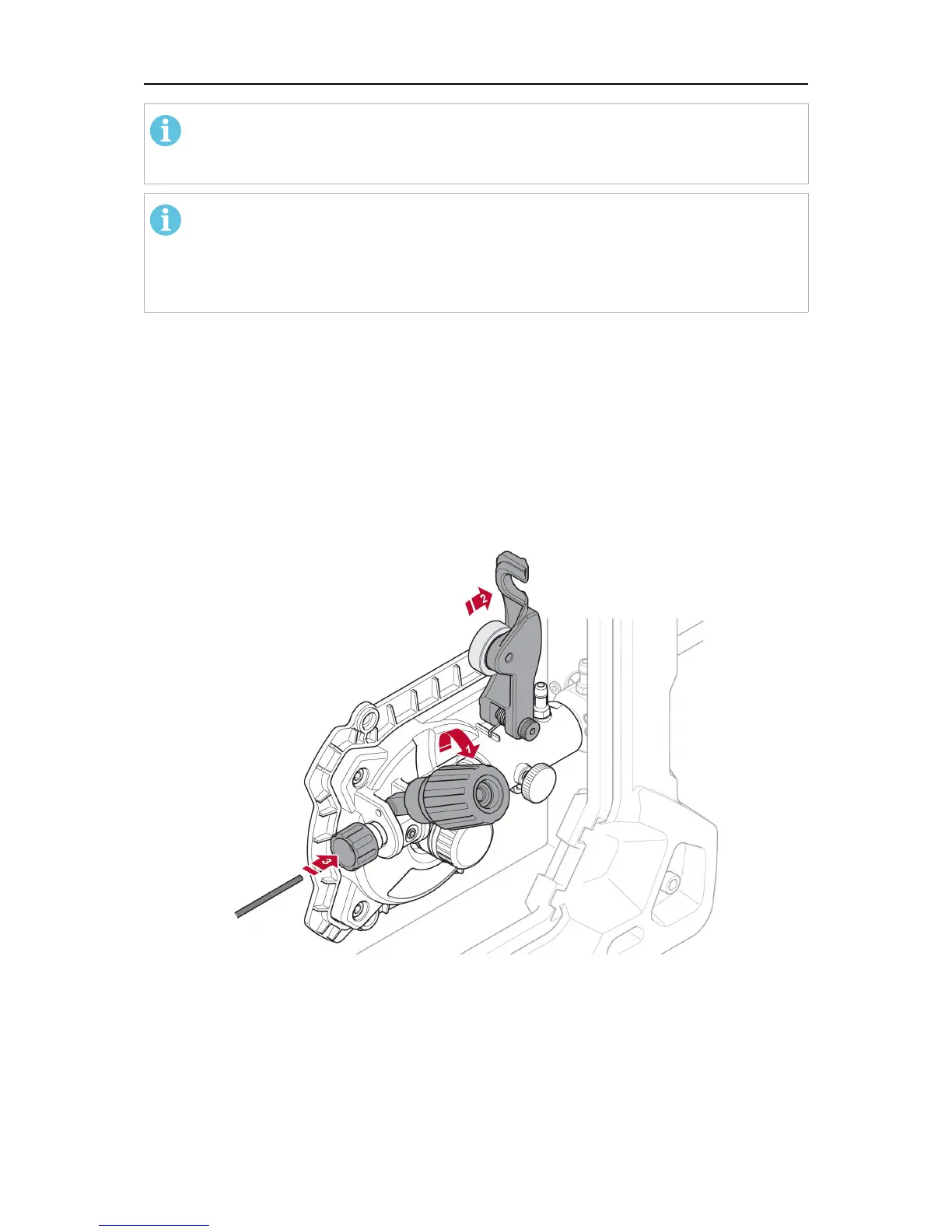

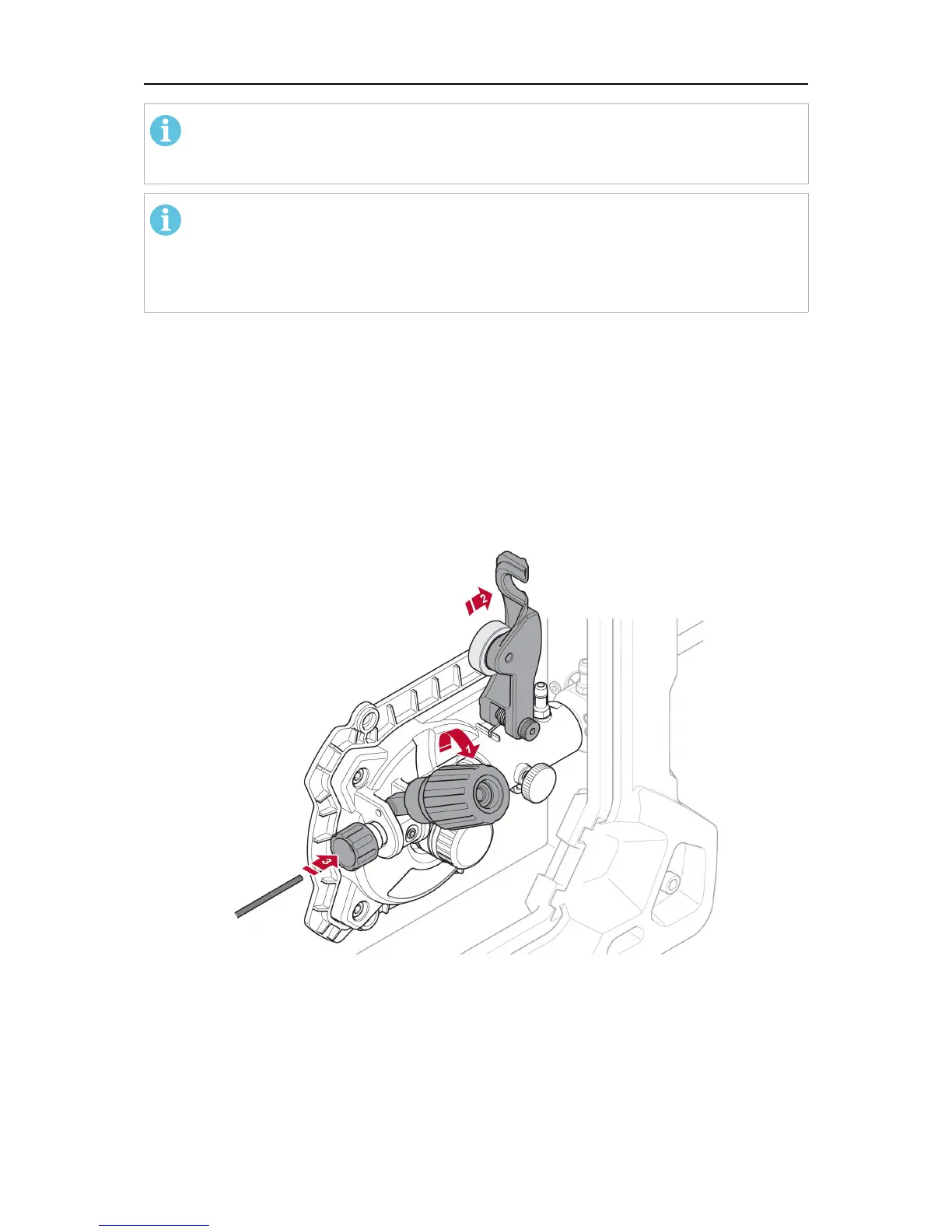

1. Open the side cover.

2. Release the pressure roller arm by pushing the tension screw toward you (1).

3. Lift the pressure roller arm up (2).

4. With the MIG welding wire feeding from the bottom of the spool pass the electrode

wire through the inlet guide (3), between the rollers, through the outlet guide and into

the MIG torch.

5. Re-secure the pressure roller arm and wire drive tension screw and adjust the

pressure if necessary. Remove the velocity nozzle and contact tip from the MIG torch.

6. With the MIG torch lead reasonably straight, feed the wire through the MIG torch by

depressing the trigger switch. Fit the appropriate velocity nozzle and contact tip.

7. Close the side cover.

Welding with aluminium wire

In order to weld with aluminium wire use optional Spool gun. Refer to Instruction manual for

Spool gun for set up.

Loading...

Loading...