5 OPERATION

0463 479 001

- 23 -

© ESAB AB 2017

5.5 Setting the wire feed pressure

Piece of wood

Start by making sure that the wire moves smoothly through the wire guide. Then set the

pressure of the wire feeder's pressure rollers. It is important that the pressure is not too

high.

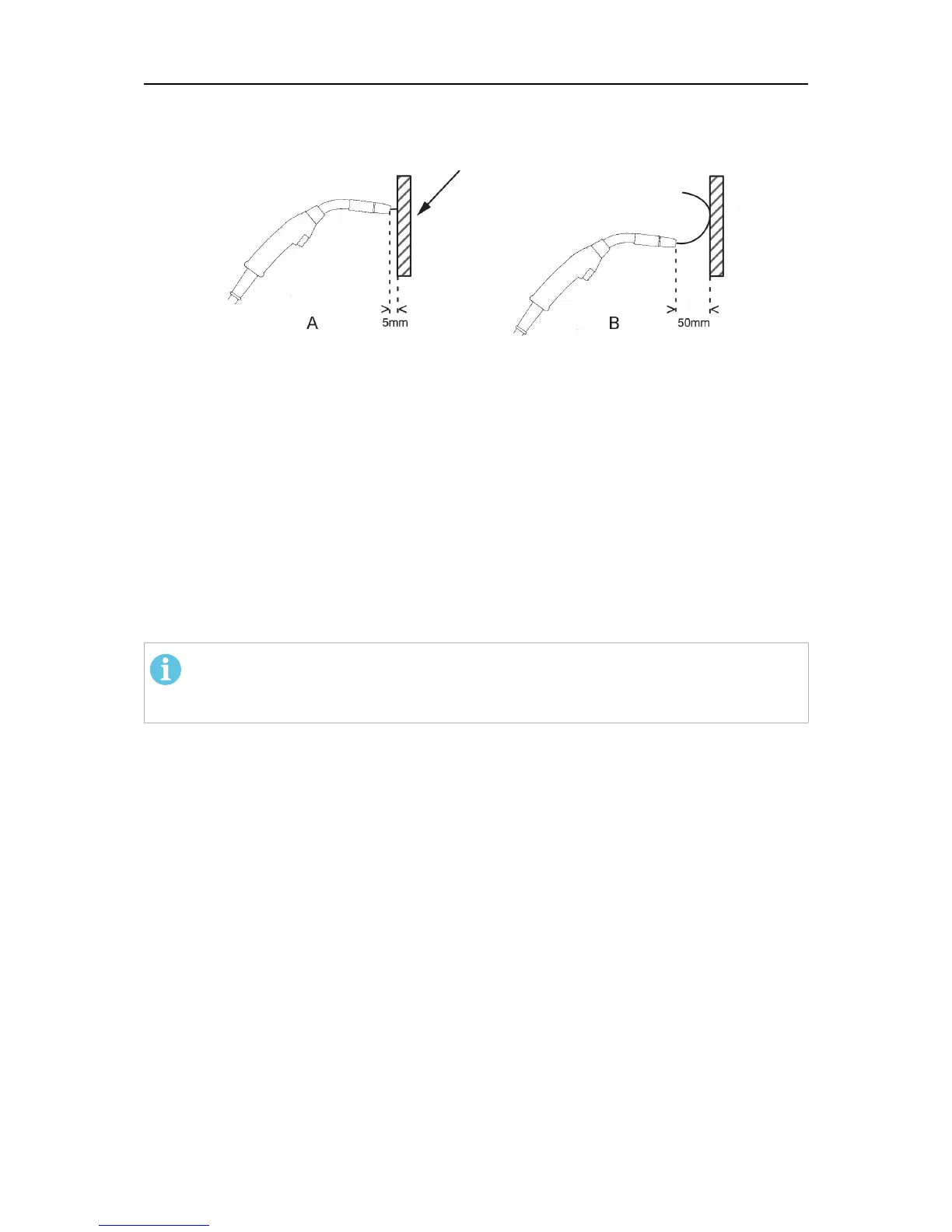

To check that the feed pressure is set correctly, you can feed out the wire against an

insulated object, e.g. a piece of wood.

When you hold the welding torch approximately ¼in. (6mm) from the piece of wood

(Illustration A) the feed rollers should slip.

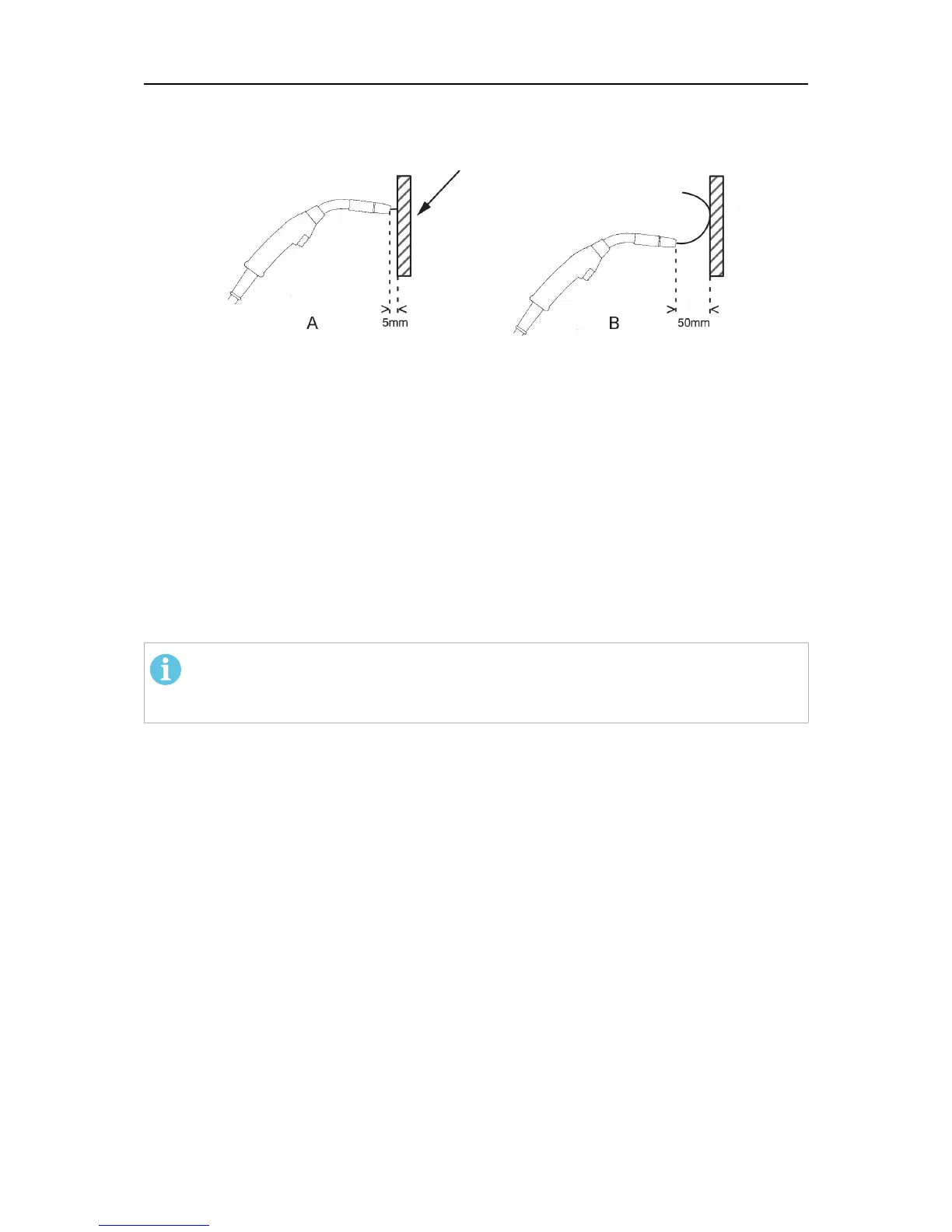

If you hold the welding torch approximately 2in. (50mm) from the piece of wood, the wire

should be fed out and bend (Illustration B).

5.6 Changing the feed/pressure rollers

Three dual groove feed rollers are supplied as standard. Change the feed roller to match the

filler metal.

NOTE!

Be sure not to lose the key that is located on the drive motor shaft. This key must

align with drive roll groove for proper operation.

Loading...

Loading...