Proceed to the Diagnostics screen and prime the IS vessel(s) three times

with methanol. NOTE: Refer to section 4.5.3 of the Diagnostics

Chapter on how to prime the IS vessel(s).

De-pressurize the system, remove the IS vessel(s) and rinse and re-fill

them with your required IS and place them back on the system.

Re-pressurized and prime a second time with the IS.

2.5.11 Water and Soil Axis Calibration

Perform a Mechanical Test; refer to section 4.5.5 in the User

Maintenance and Troubleshooting Chapter.

If the system fails the Mechanical Test, the water and soil axis will need

to be calibrated. Refer to section 4.6.1 for instructions on how to auto

calibrate the Centurion.

2.5.12 Method Build

Setup a user method by setting all times. NOTE: Make sure that

the set desorb time on the Centurion WS method is the SAME as the

desorb time of the concentrator.

Use the water waste line to monitor if the sample fill time has been set

correctly.

Verify the water sample delivery time by evidence of gas flow into the

sparge tube after complete water delivery.

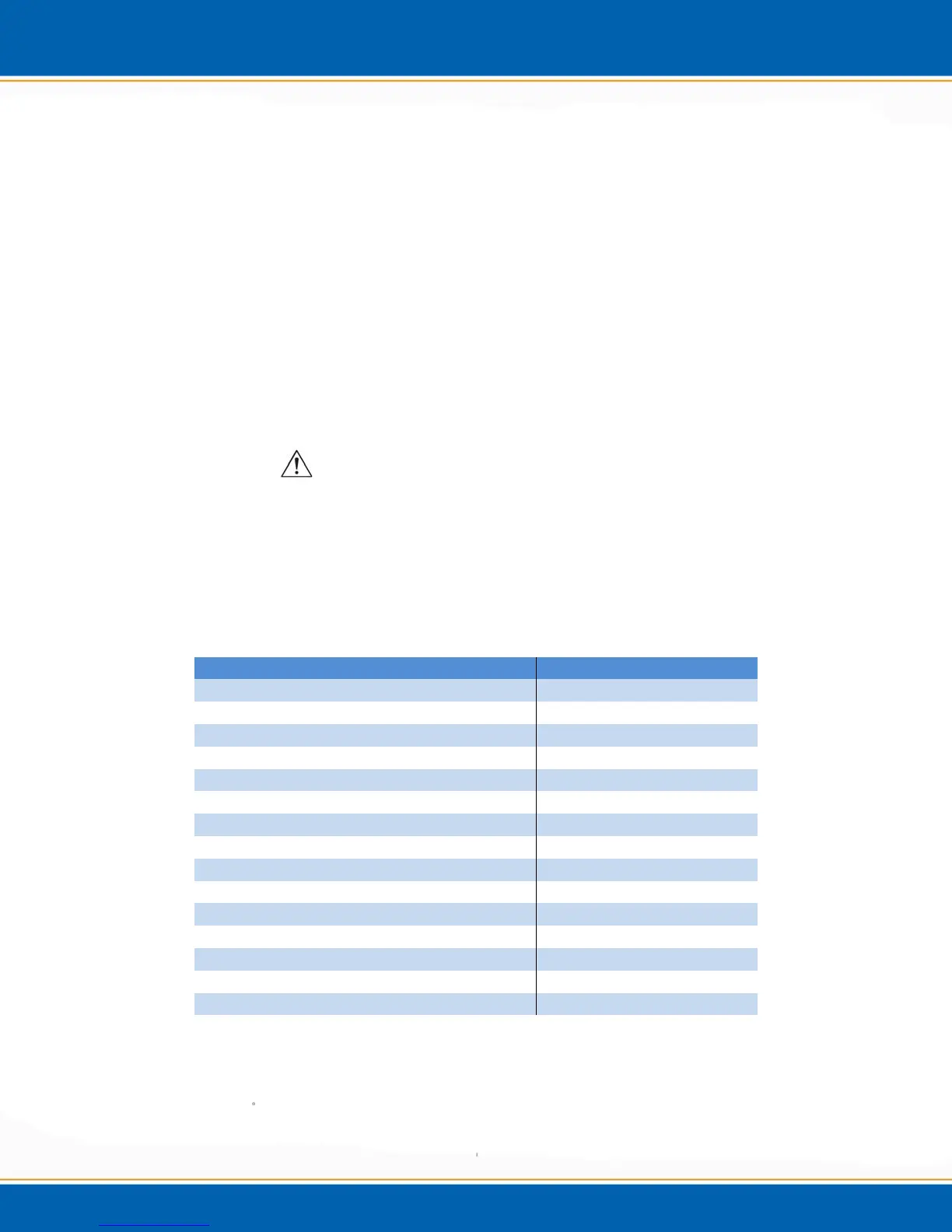

Refer to Table 2a for typical Method settings for the WS with a 5ml loop.

Purge and Trap Auto-Sampler EST Centurion WS

Sample Type Water

Sample Loop Fill Time (sec) 12

Loop Equilibration Time (sec) 5

Sample Transfer Time (sec) 15

Needle Rinse Time (sec) On/10

Needle Sweep Time (sec) 5

Sample Loop Rinse Time (sec) On/10

Sample Loop Sweep Time (sec) 5

Concentrator Desorb Time (sec) 60

Sparge Rinse Time (sec) On/25

Sparge Rinse Transfer Time (sec) 20

Concentrator #1 Cycle Time (min) 0

Number of Rinse Cycles 2

Number of Foam Cycles 1

Water Heater Temp. (°C) 85

Table 2a: Typical Centurion Water Parameters for a 5ml Loop

2.5.13 System Set-up is Complete

You are now ready to run.

Loading...

Loading...