151

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

7

FLYWHEEL AND STATOR

SERVICING

IMPORTANT: Weak flywheel magnets can

cause low alternator output and affect outboard

performance. Weak flywheel magnets can also

cause low readings on ignition test equipment,

such as a peak-reading voltmeter, which might

cause unnecessary parts replacement.

An accurate test of alternator output can help

determine the flywheel’s condition. Refer to

CHARGING SYSTEM TESTS on p. 137.

Flywheel Removal

Remove the EMM. Refer to EMM SERVICING on

p. 110.

Disconnect the vapor separator vent hose, crank-

shaft position sensor, throttle position sensor, air

temperature sensor, and oil pump electrical con-

nectors.

Disconnect the stator connector, two port side trim

system connectors, port engine temperature sen-

sor, and the port ground terminal.

Remove the four screws holding the electrical har-

ness base.

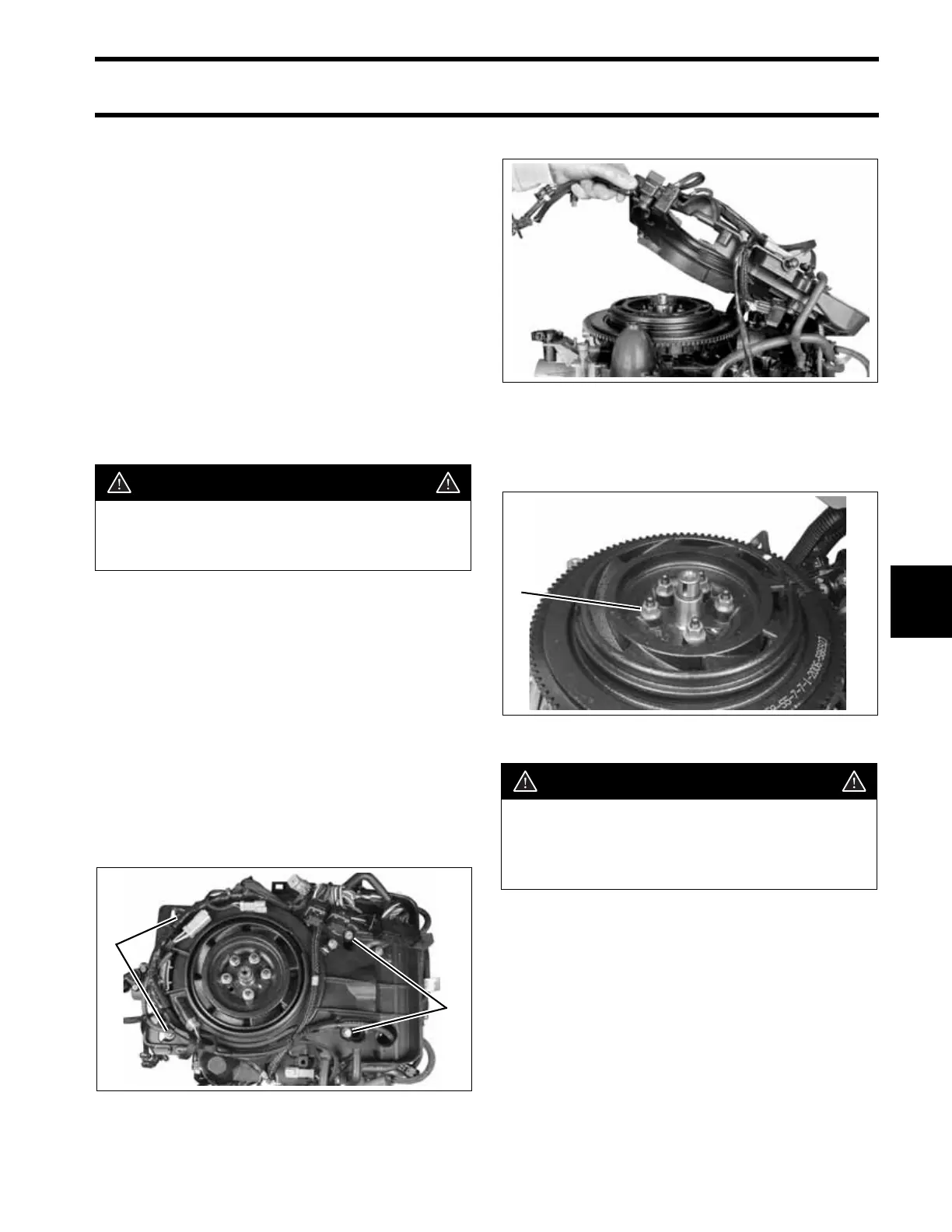

Lift the electrical harness base out of the way.

Use Flywheel Holder, P/N 771311, or equivalent,

and a socket to remove the five flywheel retaining

nuts and washers. Discard flywheel nuts.

Install bushing from Flywheel Puller Adaptor Kit,

P/N 5007181, on top of crankshaft. Place puller

from Flywheel Service Kit, P/N 434649, over

bushing.

WARNING

To prevent accidental starting while ser-

vicing, disconnect battery cables at the

battery.

1. Harness base screws 005378

1

1

005379

1. Flywheel retaining nuts 005380

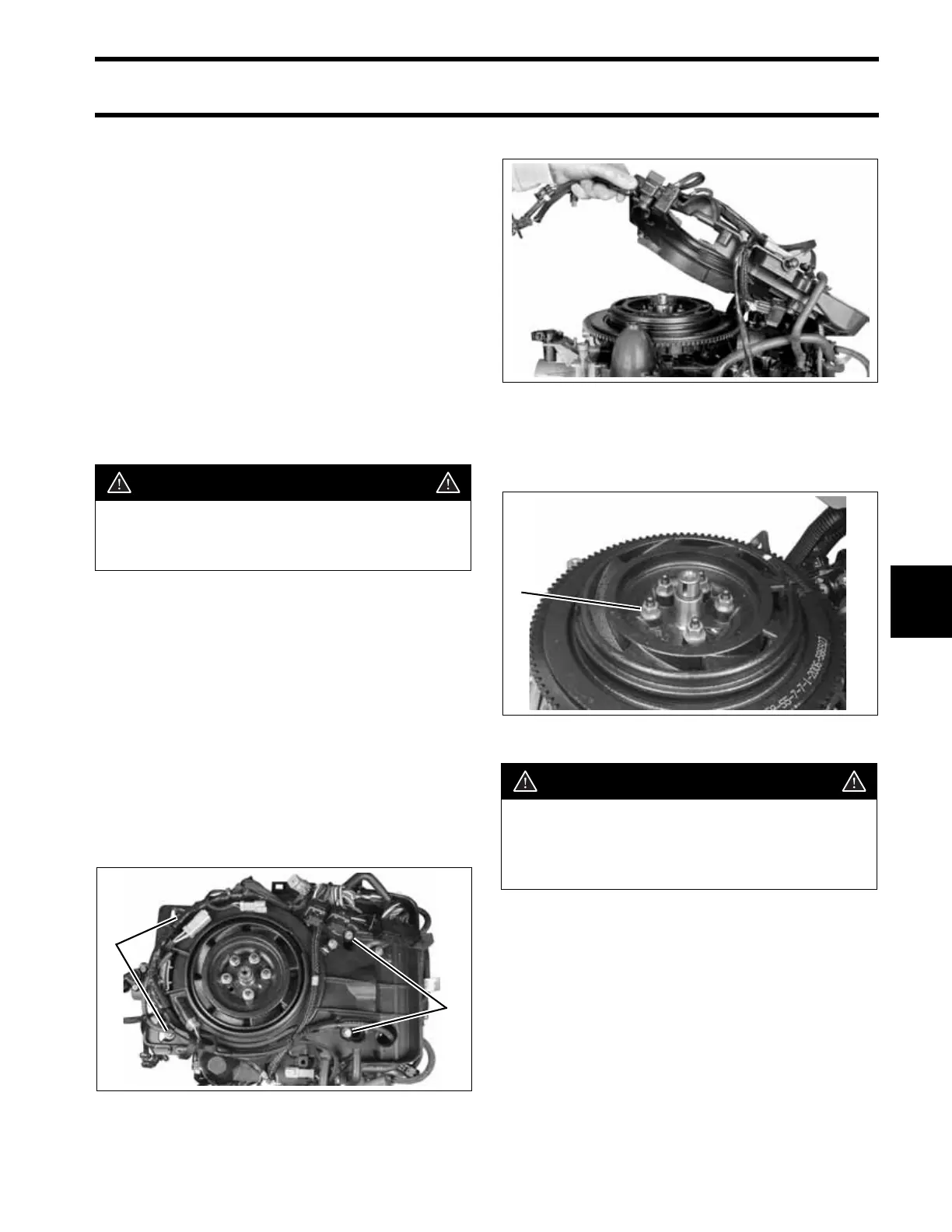

CAUTION

To avoid damage to flywheel magnets, or

injury to fingers, Flywheel service kits,

P/N 434649 and P/N 5007181, must be

used to remove or install the flywheel.

1

Loading...

Loading...