189

FUEL SYSTEM

FUEL COMPONENT SERVICING

8

supplied with all replacement injectors on 3.5 in.

floppy disk.

The following items and their mating surfaces

must be cleaned before reassembly:

• Injector

• Cylinder head

• Adapter

• Screws

• Threaded areas

Place injector and insulator in the proper cylinder

location.

IMPORTANT: Be careful not to pinch any wiring

or hoses during assembly.

Lubricate mounting screw threads and under the

head of the screw with a light coat of Triple-Guard

grease. Install washers (one per screw) on injec-

tor retaining screws. Install screws and washers

through mounting flange of injector and thread

into cylinder head.

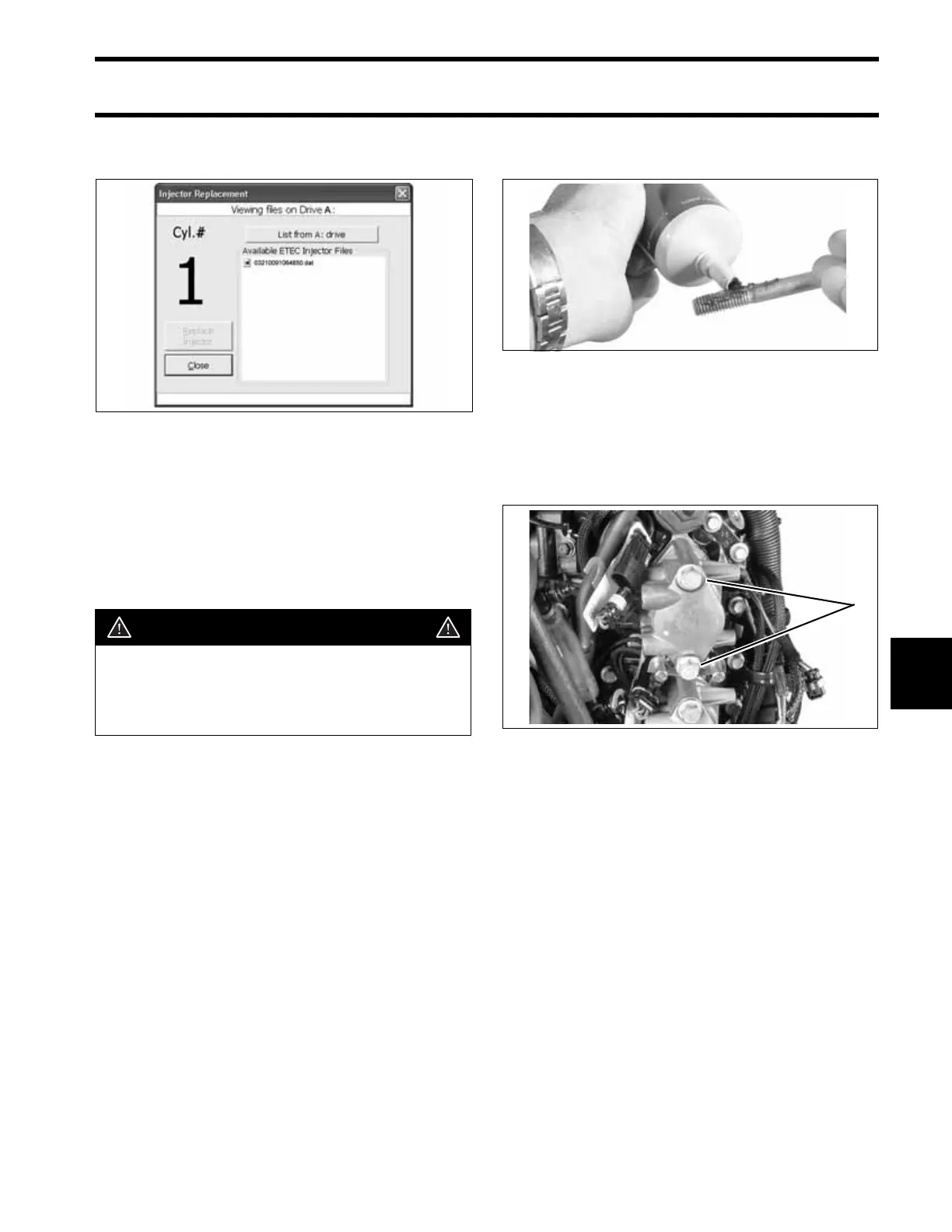

Tighten screws in stages, starting with the lower

screw.

• First torque is 5 ft. lbs. (7 N·m)

• Second torque is 10 ft. lbs. (14 N·m)

• Final torque is 24 to 26 ft. lbs. (33 to 35 N·m).

Reconnect fuel injector/coil electrical connectors.

If ignition coil lead was removed from connector,

refer to CONNECTOR SERVICING on p. 164.

Install fuel manifolds. Refer to Fuel Manifold Ser-

vice on p. 186.

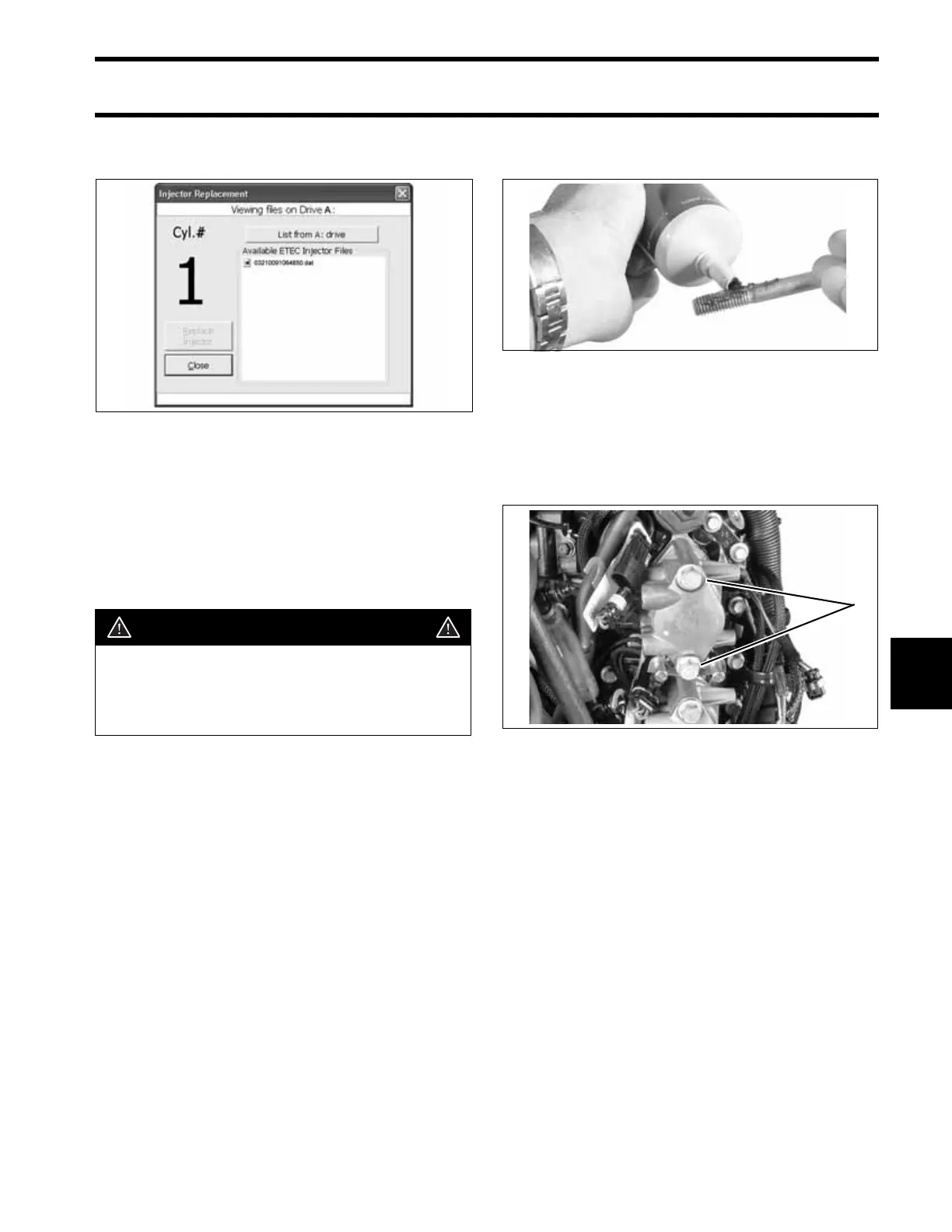

IMPORTANT: Install injector service data (3.5

in. floppy disk) by using the Injector Replacement

Utility of Evinrude Diagnostics software. Check

the Injector Coefficients screen to make sure that

all injectors are positioned properly.

004160

CAUTION

All injector components must be clean to

ensure correct torque tightening specifi-

cations. To prevent fuel leakage, carefully

follow these installation instructions.

002316

Tighten Screws in Stages

1. Screws

005338

1

Loading...

Loading...