Commissioning

Inserting the wire electrode

Item No.: 099-004934-EWM01 65

6.10.5 Inching the wire electrode

WARNING

Risk of injury due to inadequate wire feeding!

In the event of inadequate wire guidance, the welding wire can be ejected in an

uncontrolled way and cause serious injury.

• No wire feed with inadequate wire guidance!

• Check the wire guidance at regular intervals!

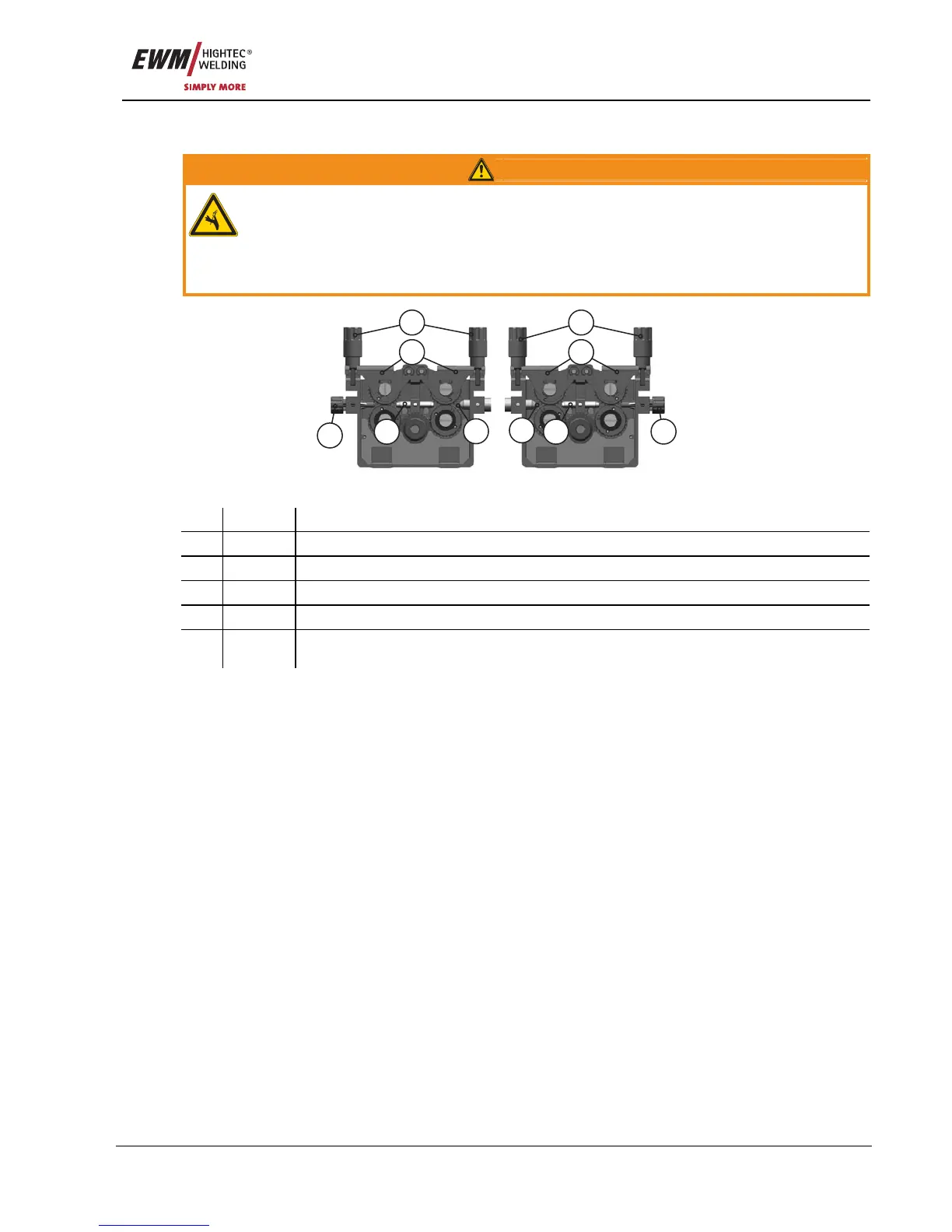

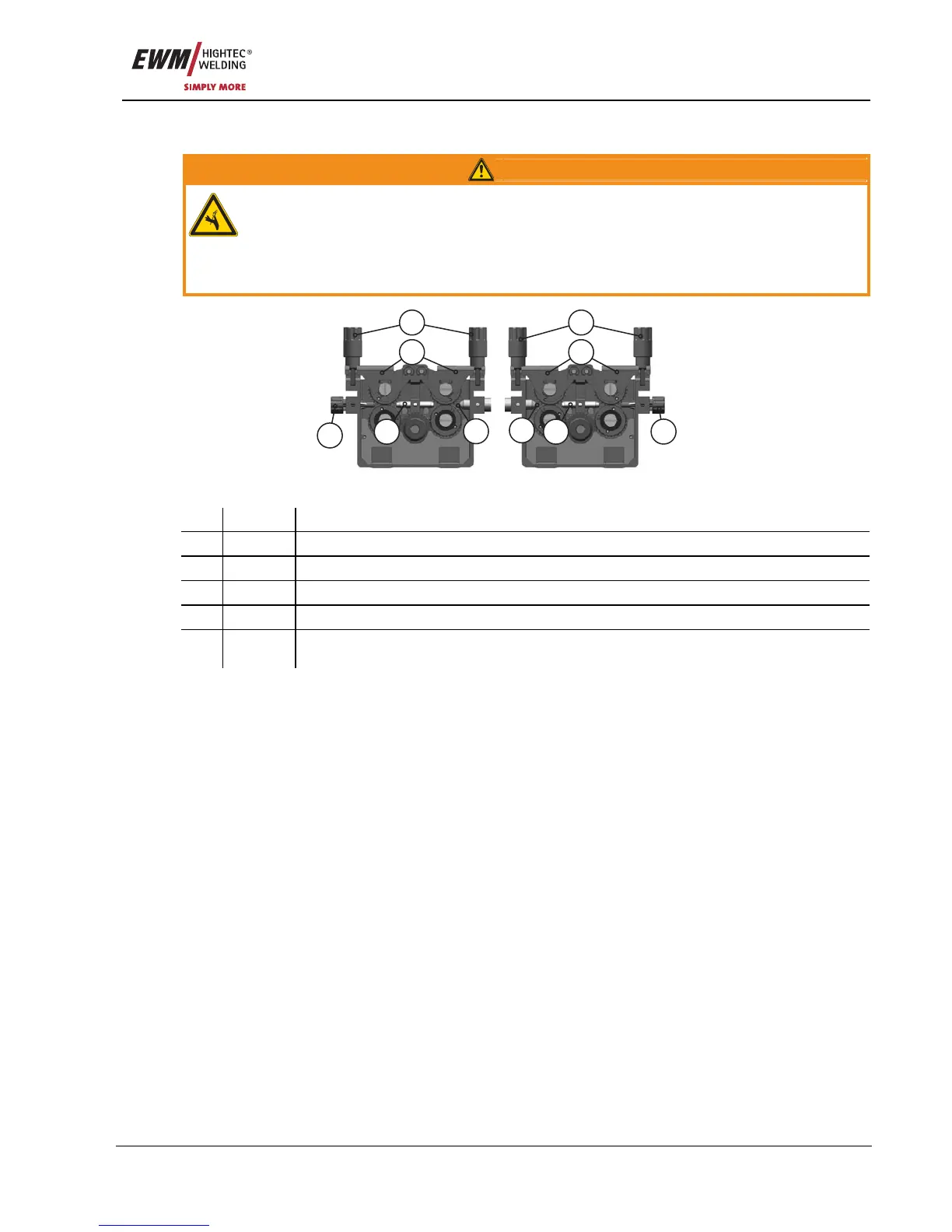

4 4

3

3

2 2

1 1

5

5

Figure 6-10

Item Symbol Description 0

1 Pressure units

2 Clamping units

3 Wire feed nipple

4 Guide tube

5 Capillary tube or plastic core with support tube, depending on the torch

equipment

• Extend and lay out the torch tube package.

• Unfasten pressure units and fold out (clamping units and counter-pressure rollers will automatically flip

upwards).

• Unwind welding wire carefully from the wire spool and insert through the wire inlet nipple over the drive

roller grooves and the guide pipe into the capillary tube and Teflon core using guide pipe.

• Press the clamping element with the counter pressure roller back downwards and fold the wire units

back up again (wire electrode should be in the groove on the drive roller).

The clamping pressure must be set on the adjusting nuts of the pressure units so that

the wire electrode is conveyed but will still slip through if the wire spool jams.

The clamping pressure for the front rollers (viewed from the direction of the feed) should always

be slightly higher than that of the rear rollers.

• Press the wire inching button until the wire electrode projects out of the welding torch.

Loading...

Loading...